Heavy Lift and Offshore Fleet of the Jumbo Shipping Company

FURTHER JUMBO HEAVY LIFT and OVERSHORE PROJECTS

Jumbo Shipping Company used their heavy lift vessels to perform fifteen loaded voyages of 131 Transition Pieces (TP) and install them onto their monopiles at a record breaking rate of one TP per day in May of 2010 for an offshore wind farm in U.K. waters. The use of quick release spreader bars, levelling and grouting using a motion compensated access system and passive lift compensators had achieved this high rate of installation. The offshore wind farm was the Greater Gabbard OWF located in the South East sector of the North Sea for client Fluor Ltd.

During 2013, Jumbo Shipping Company B.V. laid thirty monopiles for the Borkum Riffgat Offshore Wind Farm (OWF) nine miles north west of the German island of Borkum. This wind farm has thirty wind turbines producing 108 megawatts of electricity, with heavy piledriving equipment weighing in at 830 tonnes having to be brought in from manufacturer American Piledriving Equipment (APE) to install the monopiles after being loaded on to the Jumbo vessel.

The Anholt Offshore Wind Farm (OWF) involved the transport and installation of 111 Transition Pieces (TP) by Jumbo Javelin from Aalborg to the site in early 2013. The project management, engineering, and inshore loading and tow out were successfully made to install all of these TPs exactly on to their monopiles. The Anholt OWF is located in the Kattegat near Norddjurs between Djursland and Anholt island, and was opened on 4th September 2013 as a 400 megawatt wind farm in a maximum water depth of between 46 and 56 feet. The vessels Sea Installer and Sea Power completed the erection of the turbine towers, nacelles and blades in record time, with Sea Installer completing one turbine erection in only seven hours. The Danish power companies Dong Energy and Orsted Energy were involved in the completion of the project.

The heavy lift installation of subsea structures in April and May of 2015 to the Wheatstone offshore field of Western Australia involved the project management, engineering, load out and sea fastening of three voyages made from Singapore to Dampier. Sixteen subsea manifolds and associated equipment were transported to the offshore site, and were combined with an on site survey before installation, and final lifting and exact positioning of the subsea structures. The Chevron operated Wheatstone field is located 120 nautical miles north of Onslow in water depths of between 75 and 240 metres. The gas is exported from the platform to the onshore LNG facility by a dedicated pipeline.

The Papa Terra oil and gas field in the Campos Basin of offshore Brazil received a Tension Leg Wellhead Platform (TLWP) installed in 2015 and held by eight anchor piles and 128 tendon strings and eight buoyancy modules. The load outs were performed at Morgan City near the Mississippi river in Louisiana, with careful supporting of the platform during the delicate heavy lifts at the oilfield site. The Campos Basin oilfield operates at a water depth of 1,200 metres and began producing oil in 2013.

Fairplayer performed the transport and installation of a subsea crossing suspension system for the Turkish to Northern Cyprus Water Supply Project. The project is designed to supply drinking and irrigation water from a large Turkish dam reservoir to water poverty areas of Turkish Northern Cyprus. The project management, load out and sea fastening from the Port of Mersin in Turkey to the installation site near Cyprus involved an on site survey, pre-tensioning of 126 gravity anchors, tethers and buoy assemblies of this water pipeline project. The long water pipeline was completed in September 2014.

During October 2016, Fairpartner transported an oilfield riser tower of 1,525 tonnes in weight from the United Arab Emirates (UAE) to the Enfield oilfield at Exmouth Gulf in Western Australia. The riser tower was 100 metres in height and was laid horizontal on the deck of Fairpartner for delivery to clients Woodside Petroleum and Single Buoy Moorings (SBM), and was then deployed to its subsea position.

The largest underwater restaurant in the world was installed in March 2016 at Hurawalhi in the Maldive Islands. The Jumbo vessel was positioned as close as the shallow water allowed to a beach, and a large steel platform structure was lowered onto pre-installed concrete piles at a water depth of around 10 metres. After completion of the restaurant, the international tourists enjoyed drinks and meals in the surface part of the restaurant, as well as the underwater part at a depth of ten metres with ‘see through’ walls and roof in this unique underwater structure firmly built on steel.

During the early months of 2015, Fairplayer laid on the seabed the moorings at the Alma and Galia tie-back developments at the Argyll oilfield in the North Sea ready for the FPSO Enquest Producer to take up position for oil production. This ship of 99,500 dwt was built as Dirch Maersk at the Odense yard of Maersk in 1983, and was sold in 1994 for conversion to an FPSO named Uisge Gorm. The Enquest oil company purchased her in 2012 and renamed her Enquest Producer and sent her to the Blohm & Voss yard at Hamburg for conversion to a refinery FPSO. She arrived in the Tyne in the summer of 2014 for eight months of further work creating 600 jobs, moving upriver without engine power in charge of five tugs to the Hadrian yard of OGN at Wallsend. She was moved downriver to Riverside Quay at South Shields on completion of this work in March 2015, with final adjustments made to her complex refinery pipework while awaiting a calm weather window.

Jumbo Shipping B.V. was in charge of the move in April 2015 of Enquest Producer to position her above the moorings using four tugs and anchor handlers, with her anchor chains pulled in and hooked into the FPSO. When all of the mooring lines were connected, the chains were tensioned, and all excess chain, rigging and installation aids were removed. Enquest Producer was expected to produce oil for ten years, but just five years after the first oil was produced, Enquest submitted plans to the U.K. Government to shut down the Alma and Galia oilfields in April 2020. These were approved, and Enquest Producer ceased production of oil in July 2020, and was docked at Nigg Bay on Cromarty Firth on 27th October 2020.

Enquest Producer was the last of many FPSOs converted on the Tyne over several decades, and the construction yards then moved from oil industry work to the production of wind turbine towers, leg extensions, and associated equipment. The Dogger Bank Offshore Wind Farm will be the largest wind farm in the world when completed after work begins in 2023 on the installation of 190 turbines each of the Dogger Bank A and B segments of a total of three segments that will eventually produce 3.6 gigawatts of electricity. The site is 60 miles off the coast of North East England in water of depths varying from 18 metres to 63 metres. Power cables will connect to the existing converter station at Lackenby on Teesside and to a new converter station to be built at Cottingham in North Yorkshire. A state of the art Operations and Maintenance facility will be built at the Port of Tyne to service the largest wind farm in the world from a new base at South Shields on the Tyne.

The Pierce Field in the central North Sea in the three early months of 2016 saw Fairplayer and contracted vessel Olympic Zeus lay a replacement mooring system for the Haewene Brim FPSO owned by Bluewater and contracted to Shell Oil. This was an eight leg FPSO mooring system consisting of eight anchor piles driven into the seabed and connected by 1,290 metres of anchor chain and 2,300 metres of sheathed spiral strand wire to the FPSO. This was a life extension project for the FPSO with all of the mooring system loaded in German ports with a pile guide frame used to install the anchor piles within the tolerances allowed by the contractors.

A subsea tie-back located forty kilometres off Mossel Bay in South Africa from the existing FA oil production platform of the Izhwezi oilfield involved the subsea installation of an oil riser and protection mattresses by Fairplayer in early 2015. This was a development of an existing oilfield to prolong the life of the Mossgas gas to liquid plant at Mossel Bay. The client was Petrosa (National Oil Company of South Africa) and Jumbo Shipping Company had previously worked on the Izhwezi oilfield subsea structures.

The Danish waters of the German Bight sea area saw Jumbo Javelin install eighty Transition Pieces (TP), each of 330 tonnes in weight and height of 31.0 metres and loaded at Esbjerg and Aalborg, and installed on the monopiles of the Butendiek Offshore Wind Farm during the summer and autumn months of 2014. Jumbo Shipping Company designed and supplied all of the installation aids, lifting gear, sea fastenings and associated equipment, and used a fly jib weighing in at 704 tonnes on the heavy lift crane of Jumbo Javelin to handle the TPs. Jumbo Javelin needed only ten voyages from the loading ports to complete their TP installation onto the monopiles of the new wind farm.

During July and August 2015, Fairplayer laid FPSO mooring piles and ground chains for the oilfields of Dana Petroleum located 90 kilometres to the north east of the Shetland Islands and serviced from Lerwick. The contract was placed by Subsea 7 using subsea wells tied back to a centrally located FPSO, with the oil exported by shuttle tanker and the gas exported through a dedicated pipeline to the existing Tern platform in the Northern North Sea.

An indication of the colossal amount of transport work completed annually by the fleet of Jumbo Shipping Company B. V. in the oil, gas, LNG offshore fields, oil refinery and petrochemical industries, power generation and renewable forms of energy, port construction, giant ship loaders and new quay facilities, mining conveyors, floating cargo lifts, heavy crane transport, manufacturing modules and railway locomotives, carriages and rolling stock is shown by the full employment of a fleet of fourteen specialist vessels. The installation of subsea monopiles, production manifolds, modules and structures, together with the heavy lift transport of tugs, barges, yachts, tall reactor cylindrical columns, tressles and platforms, mobile cranes, heavy reels of flexible pipe, containers and general cargo, SBM single buoy moorings and many other heavy lifts of all manner of maritime and land equipment keep this heavy lift fleet based at Rotterdam very busy.

During September 2014, Jumbo Shipping B. V. completed the installation of an FPSO mooring system using Fairplayer and the contracted vessel Olympic Hera for the Greater Stella Area oilfield in the Central Graben area of the central North Sea. The mooring system consisted of thirteen anchor piles, seven kilometres of chain, 9.5 kilometres of spiral strand wire, and the mooring legs were pre-tensioned. Ithaca Energy was the developer of the oilfield, and Jumbo Shipping B. V. was managed by Costain Upstream during this work.

Fairlift sailed from the anchorage of Cascais near Lisbon in October 2015 for Rostock in the Baltic to load a partly assembled Liebherr crane for delivery through the narrow harbour entrance of St. John’s in Newfoundland. The route chosen was via the Pentland Firth, which has a bad reputation for weather and currents in winter. Four storms were encountered in the Kattegat before Fairlift avoided another during her passage of the Pentland Firth. The narrow defile of St. John’s harbour entrance was sighted on 18th November, but on her attempt to enter port the helmsman could not control the ship due to her rolling and pitching in the swell, but after switching to autopilot control she passed through into the spacious bay of the harbour to make a tricky manoeuvre to berth without thrusters as Fairlift was built in 1990 without these aids.

Capt. Denis Terpstra of Fairlift had made another interesting voyage a year earlier from Singapore to Shanghai. The transit of the 24 miles length of the Huangpu river, formerly known as the Whangpu, to the financial tower buildings of the Pudong area and onwards to her upriver berth to load three knuckleboom cranes, each of weight 235 tonnes, took seven hours. The total length of the manmade Huangpu river is 70 miles, and it was first excavated and created by the ‘Four Lords of the Warring States’ of China. Fairlift was sold in 2020 and was trading as Maher under the flag of the Togo Republic.

During June 2015, Jumbo Jubilee loaded two French naval minehunters using special lifting cradles that wrapped around their hulls, and transported them to the Persian Gulf for a joint exercise with similar craft of the United Arab Emirates (UAE). At the end of the exercises, Jumbo Jubilee reloaded the minehunters and returned them to the French naval base of Brest.

During August and September 2017, Jumbo Javelin made two voyages each of 22 days duration from Tianjin in China to Richards Bay to the north of Durban in South Africa with two shiploaders for client Sandvik. The shiploaders were loaded athwartships across the deck of Jumbo Javelin with their booms projecting over the port side, and after installation they increased coal loading at Richards Bay from 8,500 tonnes per hour to 12,000 tonnes per hour. The shiploaders were loaded and discharged using the ‘forklift’ method, comprising two lifting beams firmly connected to each other and acting as a lifting platform placed underneath the shiploaders.

During the end of 2017, 60 yellow Transition Pieces (TP) were installed by Fairplayer in the German waters of the Baltic Sea for the Arkona Becken Sudost OWF. This included the loading out of the TPs at Sassnitz, each of weight 290 tonnes and height of 18.0 metres, offshore transport, and the use of hydraulic lifting beams, lift compensators, and installation aids for clients EON and Van Oord Offshore Projects. There was a tight range for the fitting of the TPs with careful alignment and bolting of the TPs onto the submerged monopiles.

Moheskhali Island in offshore Bangladesh was the setting for the mooring installation of a Floating Storage Regasification Unit (FSRU) by Fairplayer during the early months of 2018. The Macgregor mooring system components were loaded out and consisted of eight anchor piles, eight bottom chain segments, a steel landing structure for the oil turrets on the seabed, and over 150 bags of rock to prevent scour around the subsea structures. The work was difficult due to strong currents, poor visibility, and the very remote location for clients Geocean Entrepose and Excelerate Energy.

The offshore Kribi oilfield in Cameroon saw Fairplayer install a soft yoke mooring system for the Hilli LNG vessel in the summer of 2017. Pile driving of the anchor base, anchor piles, and lifting of the yoke weighing in at 704 tonnes, and connection of risers and control umbilical lines involved difficult hook up work in this warm African offshore location. The clients were Golar LNG and Perenco with jack hammers used during the pile driving, and yoke installation, grouting and levelling work performed by the Jumbo Shipping Company and partner N-Sea.

The ERHA FPSO working for Mobil Oil in offshore Nigeria was the scene for Jumbo Shipping Company to install a Calcium Nitrate Injection Vessel (CNIV) to increase the flow of oil to the FPSO. This new type of injection module, weighing in at 100 tonnes, was loaded out by Jumbo Javelin of the Jumbo Shipping Company fleet during July 2018 at Lagos. The operating limits at the site were carefully assessed and the heavy lift was executed safely to allow the CNIV module to be aligned precisely onto its intended position.

Fairpartner transported two container cranes weighing in at more than 1,500 tonnes each from Taicang in China to Immingham during 2018. The cranes were manufactured by Nanhua International and weighed 788 tonnes and 810 tonnes on a voyage that lasted 36 days, with the container crane jibs having to be lowered to pass under the Mubarak Peace Bridge in the Suez Canal. Fairpartner had to widen her portside by 6.1 metres by using her ‘tween decks as extensions to accommodate the cranes, with a 100 tonne counterweight on the starboard side during lifting operations. The tricky part of the voyage was the narrow Immingham access dock with the container jibs then raised on arrival at Immingham to pass through the narrow entrance lock giving access to the calm water berths at Immingham Dock and separated from the open water berths on the Humber used by large bulk carriers bringing in biomass and other cargoes. The access dock accepts a maximum vessel beam of only 26.8 metres, and the clearance margins at high tide of Fairpartner and her load were only one metre horizontal clearance and three metres vertical clearance from the dock structures. Fairpartner then transported two heavy eco hoppers from Holland to Australia for client Breston B. V.

RECENTLY COMPLETED JUMBO SHIPPING COMPANY PROJECTS

During 2019 and 2020, many important contracts were completed, including a valuable contract won by Jumbo Shipping Company in April 2020 for the installation of wind turbines on the Yunlin OWF project in offshore Taiwan.

This would require new switchboards and power management systems to power the thrusters and electrical equipment of Jumbo Javelin, chosen for the project. The Jumbo team of specialists were prevented from flying from Rotterdam to Singapore to make the updates due to Corona virus, thus Solis Marine provided assistance to Jumbo at Singapore in August 2020 for these alterations to her working gear.

Jumbo Javelin was working on the Yunlin OWF project in November 2020 together with a chartered anchor handling tug. Twenty heavy lift shipments of monopiles, transition pieces (TP) and other cargo were made from Laem Chabang to Taichung, giving a total weight of cargo of 7,500 tonnes of steel. The first shipment was made in October 2020 by Jumbo Javelin, with side and stern loading ro-ros also chartered for this big project.

The remainder of the Jumbo fleet were dispersed around the world at this time in early November 2020 with Fairmaster at Eemshaven, Fairpartner at Gibraltar, Fairplayer at Algeciras, Fairlane anchored off Luanda (Angola), Fairlift at Limassol, Fairload at Durban,

Jumbo Kinetic was transitting the Panama Canal, Jumbo Jubilee was in Singapore, Jumbo Vision was at Setubal, while Stellanova was anchored off Vladivostok.

Stellaprima had arrived in the Tyne from Halden in Norway to load heavy reels of flexible pipe, which she transported to Flushing. Fairmaster was transporting 165 monopiles from Rostock to Eemshaven and 135 yellow Transition Pieces (TPs) from Aalborg to Eemshaven in connection with the Hornsea 2 Offshore Wind Farm, adjacent to Hornsea 1 OWF around 65 miles off the Yorkshire coast. A contract had been won from client DEME, a leading dredging and offshore contractor, for the transportation, in turn awarded from Orsted Energy for this 1.4 gigawatt power OWF.

Jumbo Javelin had in early 2020 transported four new trawler hulls, each weighing in at 500 tonnes, from Vietnam to a shipyard in Norway for deep sea fishing off Norway. She was anchored off Kaohsiung in November 2020 working on the Yunlin OWF project.

The El Hamra oil project in Egypt used Fairplayer in June 2019 for the pre-tensioning and installation of a shallow water CALM buoy mooring system at a water depth of 26 metres for the Mersa El Hamra offshore terminal near El Alamein. This involved the laying of ten huge drag anchors and six chain moorings and associated mooring equipment for this new oil terminal.

Jumbo Vision during 2019 made five voyages from the Mediterranean ports of Toulon, Tarragona, Algeciras, Genoa and Piraeus to ports in Florida, Texas and Louisiana of the U.S.A. One cargo consisted of nine large yachts and super sized motor cruisers, while other cargoes carried included a 368 tonne urea reactor, an 87 tonne temperature shifter unit, and a 23 tonne methanator unit.

In between two of these voyages, Jumbo Vision managed to make a short coastal voyage between Malaga and Motril, a sugar port in Andalucia, to transport a 230 tonne harbour mobile crane, and also to move a Gottwald crane of 426 tonnes within Castellon harbour to a new site.

Jumbo Vision in the summer of 2020 picked up an empty carousel of 24 metres in diameter from the headquarters of Subsea 7 in Dusavik in Norway and transported it to Halden in Norway to load subsea umbilical cable, the combined weight of carousel and umbilical being 1,255 tonnes. She then returned to Dusavik to trans-spool the umbilical to Seven Arctic, a Subsea 7 offshore construction vessel.

The latter vessel was on contract to the Angolan offshore oilfield of Total, and after her arrival in these waters in October 2020, Fairlane arrived with a cargo of ten loaded flexible pipe reels from Denmark. Fairlane then supplied reels consecutively to Seven Arctic at the site 150 kilometres off the Angolan coast, and then returned the empty reels to Denmark.

The Port of Sergipe in Brazil comprises an LNG Terminal together with a 170,000 cubic metre Floating Storage Regasification Unit (FSRU), an LNG pipeline of 6.5 kilometres in length, and a gas powered electricity station of output of 1,516 megawatts. Jumbo Shipping Company was awarded a contract for the FSRU mooring system in 2019 including the hook-up of risers and umbilical lines to the FSRU.

Fairmaster in 2020 loaded sixteen large petrochemical columns and placed them horizontally on her long deck, together with general cargo, at Mailiao in Taiwan for clients Pacific Ocean Group and Formosa Heavy Industries for delivery to Point Comfort in Texas via the Panama Canal. The columns and cargo weighed in at a total of 6,695 tonnes, and included three ultra heavy columns, one Wash Tower of 1,720 tonnes and 105 metres in length, and two oil reactor columns weighing 1,147 tonnes each. In a separate voyage, she transported two giant shiploaders from the Port of Gdynia in Poland to the Port of Djen Djen International in Algeria for a new life at this new container port near Skikda to the east of Algiers.

Geodis Wilson was the client in Australia using Jumbo Jubilee for two voyages to the Amrun Bauxite Project in Northern Queensland near Cape York. She transported a heavy stacker, heavy reclaimer, and a giant shiploader for the Rio Tinto Alcan bauxite plant at Weipa from Henderson, and discharged all of the cargo onto a barge in the Hey river at Weipa. Weipa has seen this large Rio Tinto Alcan aluminium plant in operation for several decades in this remote location.

A subsea production manifold weighing in at 410 tonnes was successfully installed by Jumbo Shipping Company off the coast of Israel at a water depth of 1,643 metres on the Leviathan oilfield situated 125 kilometres west of Haifa and 35 kilometres west of the other Israeli Tamar oilfield for client Technip FMC during 2020. More projects were completed during this year, including a decommission contract from Taqa Energy to remove, transport and dispose of three subsea protection domes and piles from a North Sea field.

Jumbo Kinetic had been kept busy during 2020 in transporting multiple cargoes, including a 1,250 tonne turret buoy mooring system from Dubai in the UAE to a position 150 kilometres west of Lerwick in the Shetlands, and two ethylene oxide reactors weighing in at 1,140 tonnes each from Hazira in India to a port in the U.S. Gulf. These heavy lifts were all transported on the same voyage, with the cargo for America delivered first, and then a Transatlantic voyage to the Shetlands for the remaining cargo. Jumbo Kinetic then sailed to Trelleborg in Sweden to pick up two heavy gangway structures, each weighing in at 300 tonnes for discharge in the U.S.A. with very careful lifting during loading and discharge as each gangway had a glass roof. Jumbo Kinetic also lifted in August 2019 a record breaking Wash Tower of 1,929 tonnes and four columns including transport saddles from ports in China and Korea to the Jubail JUPC project in Saudi Arabia. This was the heaviest ever tandem crane lift for the company with the Wash Tower having dimensions of 101.1 by 10.8 by 11.4 metres.

At the end of 2020, her sister Fairmaster moved to Mipo in South Korea to load the heaviest fractionator in the world and other propylene, ethylene and gasoline fractionators at Nantong in China together with a quench tower for Tanjung Setapa in Malaysia.

The fractionators varied in weight from 1,003 tonnes to 1,911 tonnes with dimensions varying from 121.3 by 11.2 by 10.6 metres to 64.0 by 8.9 by 8.7 metres. The client was Toyo Engineering, which is building a refinery with a capacity of 300,000 barrels per day of crude oil to supply naptha and LPG to a gasoline and diesel producing petrochemical complex.

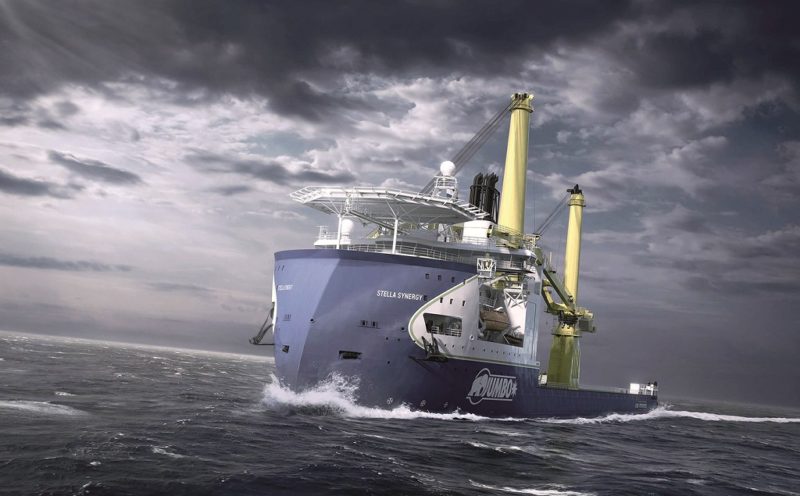

NEW SUBSEA and HEAVY LIFT VESSEL FOR JUMBO SHIPPING COMPANY

A multi-functional XBOW dynamically positioned Heavy Lift Crane Vessel (HLCV) was expected to enter service during March 2020 as Stella Synergy for Jumbo Shipping Company. She has an overall length of 185.4 metres, moulded beam of 36.0 metres, moulded depth of 12.6 metres, with comfortable accommodation for her crew and 150 offshore workers. She is equipped with a helipad for a Sikorsky S-92A helicopter, a mast crane of 2,500 tonnes lifting capacity and can work in water depths of up to 3,000 metres.

She has dual fuel engines and can operate at a service speed of 15.0 knots on cleaner natural gas (LNG), and is currently the largest XBOW hull design vessel operating in the world.

The main crane has a triple hoist and an active heave compensation auxiliary block of 600 tonnes capacity. The second crane for heavy lift and subsea work has a lifting capacity of 400 tonnes, and also has an active heave compensation main hoist. This new Heavy Lift Crane Vessel (HLCV) combines technical efficiency and fuel economy together with the highest standard of safety for her crew and contract workers in a new, clever and exciting way for all of her future heavy lift and offshore projects.

The general design of Stella Synergy was by the Ulstein yard in Norway, a yard noted for a long line of offshore ships since their well designed first ships appeared in the North Sea oilfields in the 1970s.

A contract was signed on 8th December 2017 with China Merchants Industry Holdings (CMHI) for the detailed design and construction of the vessel in China. Stella Synergy will work on wind farm monopile, transition pieces (TP) and wind turbine tower, nacelle and blades installations, as well as on oil and gas fields with their FPSO, FLNG and FSRU heavy mooring systems. Huisman Equipment has supplied both of the cranes of the new XBOW design ship, with the latest vessel in the offshore Van Oord fleet of the same XBOW design and named Bravenes at the Ulstein yard. Jumbo Shipping Company ran an internal company employee competition to name the ship, with three names on the shortlist before the final name was chosen.

Stella Synergy will work on complex subsea infrastructures involving subsea heavy lifting to the seabed wellheads, installation of mooring systems for Spar and Flexlay systems.

She will also work on wind turbine farm foundations and installation of turbines, and on all types of worldwide transport and heavy lifting of project cargo for oil and gas projects, and the offshore removal of redundant oil and gas facilities.

HEAVY LIFT CLUB

Jumbo Shipping B. V. belongs to the Heavy Lift Club (HLC), which was formed in Antwerp on 1st June, 2009 by 15 specialised heavy lift carriers in a forum to represent the industry and to discuss industry issues e.g. the overprovision of container terminals worldwide to the detriment of new quay facilities for heavy lift cargo. Some other members at that time were Beluga Project Carriers, HLL Heavy Lift Shipping, American Heavy Lift Shipping, Songa Shipping, AHL Shipping Company, Nordic Heavy Lift ASA, SMT Heavy Lift (Europe) B.V. and Rickmers Line. Several of the Heavy Lift Club members have since gone out of business or have merged together in this highly competitive and specialised area of shipping.

HLC is a worldwide club of owners of heavy lift ships, multi axle trailers and specialist engineering equipment, tug and barge owners, crane owners and operators, steel fabrication companies, rail equipment owners for heavy cargo, port and terminal operators, engineering services and special rigging and skidding equipment for heavy installations, and rigging and heavy equipment lifters. The members collaborate together in an attempt to gain additional business.

In common with all members of the Heavy Lift Club, Jumbo Shipping Company operate a Quality Health and Safety (QHSE) program, with employees expected to intervene if they see a potentially unsafe situation and they are required to stop work if they feel in any way unsafe.

The huge heavy objects handled by the deck crews of heavy lift ships, with full safety clothing and gloves to handle the bolts and linkages, are required to be manoeuvred by the heavy lift cranes with a precision of a few millimetres. Jumbo Shipping Company had trialled at Rotterdam in February 2020 on Fairlift a new remote controlled crane lifting safety system designed to cut down accidents, and developed by Verton Technologies of Australia.

POSTSCRIPT

The death was announced on 18th May 2018 of the founder of Jumbo, Hans Kahn, at his home in Caesarea in Israel at the age of 95 years, surrounded by his family including his son Michael Kahn and friends. Jumbo Shipping Ltd. is still a family owned company and is managed by Michael Kahn, who joined the Board of Directors as Managing Director in 1990 at the age of 28 years. The founder had a vision of a dedicated concept for handling heavy lift items that were not suitable for container or pallet handling.

The vessel Stellaprima was introduced in 1955 with the co-operation of Borchard Lines. Tributes were paid by Michael Kahn, Peter Bloch, formerly Commercial Director of Jumbo, Richard Borchard of Borchard Lines and a long time friend, and the directors of the Huisman Equipment Heavy Lift Crane company, which was founded in Rotterdam in 1929 as a steel stockholder, later building very famous floating cranes such as Taklift 4 in 1980 of 1,600 tons lift capacity for Smit Tak and many other heavy lift cranes.

Hans Kahn had a long and eventful life, having survived World War II after serving in the Dutch Navy in exile.

A partnership by Jumbo with Arkon Shipping and Projects was created in March 2015 but was dissolved exactly a year later. Jumbo Maritime N.V. then entered into an exclusive partnership in October 2017 with BBC Chartering for the transport of project cargo under the name of the Global Project Alliance (GPA).

The two family run companies then tendered for projects together while retaining their independence. Jumbo Maritime N. V. has its Headquarters Office in Havenstraat at Schiedam in Holland, and its Branch Offices in Houston, Singapore and South Korea, and over twenty offices of agents in the Far East, Europe and the Americas, all actively seeking heavy lift work for the combined fleets. BBC Chartering has a very large fleet of 160 ships of all sizes and equipped with a variety of heavy lift cranes. Their offices around the world offer heavy lift and project cargo solutions for customers using vessels in the range of 3,500 dwt to 37,300 dwt with lifting capacities of up to 800 tonnes. New vessels coming into service will lift this upper limit to 900 tonnes and will be able to serve almost any port and offshore operation anywhere in the world.

Jumbo Shipping Company and Jumbo Offshore have vast experience in the safe transport for worldwide clients of heavy lift items by sea, and in offshore subsea structures, drilling templates, conductors, pile driving, modules, SPM single point mooring systems, and multi anchor mooring systems for giant FPSO, FLNG and FSRU vessels.

The future prospects for the company are very good as long as the price of a barrel of Brent crude oil remains relatively high. However, this oil standard price fell below $40 for a barrel of Brent crude oil during part of November 2020, and actually fell by 9% in one day. This volatility is nothing new to major heavy lift and offshore companies such as Jumbo Shipping Company and its staff.

I wish to very sincerely thank the excellent website of the company at www.jumbomaritime.nl for the very good presentation of the company history and clarity of information of their descriptions of their many important projects.

The web blogs of their hard working Masters tell a story of technical mastery of the subject of very heavy lifting, as well as of patience when reducing speed after encountering or trying to avoid heavy storms.

Comments

Sorry, comments are closed for this item