One of the most interesting shipbuilding concerns of Tyneside was founded by Charles Mark Palmer and his brother George in Jarrow in 1851. Their names, along with those of William (Lord) Armstrong, Charles Mitchell and George Hunter changed the industrial landscape of Tyneside during the Victorian age. Charles Palmer was born at South Shields in 1822 and began his career in his father’s shipping business in the village of Jarrow but then branched out on his own, taking an interest in the John Bowes colliery whose output was sent to London on small sailing brigs. Jarrow was a small village on the south bank of the Tyne three miles from the river’s entrance, which had in earlier times built frigates during the Napoleonic wars. The Brothers leased some land to start shipbuilding as Palmer Bros. & Co. to build iron steamers for the coal trade which was the river’s main industry. The second ship they built was to revolutionise the trade.

John Bowes (above), of 437 grt ,650 dwt, was launched on 30th June 1852 and is generally regarded as the world’s first screw collier. It was powered by a twin cylinder engine built by Robert Stephenson’s works in Newcastle (this company would eventually become absorbed into the Palmer’s empire in 1912), aided with sails she could reach 8 knots, it cost £10,000 to build when an average sailing brig would cost £800 to £1,000.

Her maiden voyage took place on 29th July 1853, arriving back in the Tyne on 3rd August. Having completed the journey to the West India Docks in 48 hours, and took 18 hours to discharge.

The ship carried three times as much as a brig, which would take a month to get there and back.

The ship made its money back within a year, and the company quickly received orders for several others, leading to the death knell of the collier brig, which had almost disappeared from the East coast by 1873.The success of the venture led to great expansion.

The London gas industry was expanding quickly and had a huge demand for coal and large contracts were to be had. Palmer bought fourteen collieries to safeguard the supply of coal. Another collier the Samuel Laing of 606 grt, was built for Wm. Cory and partners and was the first of thirty colliers and lighters to be built for them.

In 1853 they started their own engineering business, and iron foundry, with boundless ambition the company prospered. A year later they received an order from The Admiralty for the armoured battery Terror. By 1855 twenty more colliers had been built. In 1854 the first rolled armour plates were produced for warships.

In 1865 Palmer managed to purchase ironstone mines a Port Mulgrave on the north Yorkshire coast near Staithes, and set up a rolling mill and four blast furnaces at Jarrow, for the production of up to 1,000 tons of pig iron, a week. The colliers on their return trips from London, called at Port Mulgrave and loaded the ironstone and limestone for delivery to the jetty in front of the furnaces. In the same year the newly amalgamated North German Lloyd company ordered six 500 grt passenger cargo ships for their new service to New York.

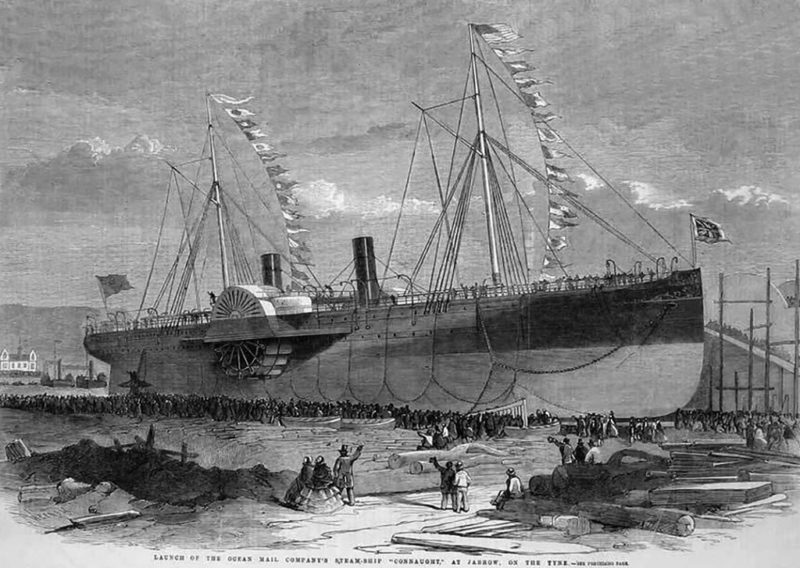

Charles Palmer soon got a reputation for his willingness to accept contracts for out of the ordinary ships. In 1860 he took on a contract for two ships for the Galway line but the specification was impossible and he incurred a large loss. The two 3,000 grt ships, Connaught (above) and Hibernia (launched as Leinster) were for the Galway to Boston passenger service. The new Connaught was destroyed by fire 150 miles off Boston on her second return voyage in September 1860, after five months in service, while Hibernia was sold in 1869 and was converted into a cable layer.

With the expansion of the railways and industrial growth it attracted a great influx of folks from Ireland looking for work in the pits, railways and the shipyards.

Andrew Leslie came to Hebburn from Aberdeen in 1853, where he had run a small engineering business, but moved south to establish a shipyard at two miles upstream from Jarrow. Many of Leslie’s fellow countrymen flocked to the area to be employed in the yard, he also built 400 houses, to the extent that the town was known locally as ‘Little Aberdeen’.

In 1859 Palmer opened a second disused shipyard at Willington Quay on the opposite bank of the river and by 1860 3,500 were employed.

Palmer was always on the lookout for novel ways to attract publicity for the Company. On 15th August 1863 he arranged for four ships to be launched at the same time. John M.McIntyre (985 grt) and The No. 1 (730 grt) were launched from the Willington yard, while from the opposite bank Europa (1,284 grt) and Latona (699 grt) took to the water at Jarrow. At 4 pm,a gun was fired as a signal to launch the four ships, and when the last ship was clear of the ways, a second gun announced the success of a unique event. The criss-cross launch of four vessels was an unparalleled event in shipbuilding annals at the time.

In 1861 there were 3.55 million tons of coal shipments to the Thames by sea while 1.64 million tons by rail.

In 1864 it was reported that Palmers was the only shipyard in England where every branch of manufacturing was done on the premises, from delivery of ore at one end of the yard to delivery of the finished ship.

The Jumna (above) was the largest ship built by the Company which was 360 feet long and of 6,311 tons displacement, and was one of a class of five ships built to the order of The Admiralty, and whose contract was for £187,650 each ship. As a troop ship, it was capable of carrying a whole battalion and their families 1,200 people, for service with the British Army of India. Admiralty inspectors at the yard caused delays in her construction. Just before her launch in September 1866 flaws in the shell plating were spotted. The delays while they were replaced delayed the launch by a month, by which time it had been on the berth for two years. Poor quality of cordage for her extensive rigging had to be replaced too. The Palmer’s yard managers must have thought that their troubles were over, and gave a ball onboard for the Captain and his Officers just prior to handover in March 1867. But the next morning the Admiralty Inspector reported that the carpet of the saloon had been worn thin by all the dancing, and he would not accept it, until it was replaced at the builders expense! One only can imagine the sense of relief of the builders as the ship finally sailed out of the river.

Meanwhile the company continued to make money from the bread a butter contract in building eight colliers in 1866.

On 21st July 1865 Palmers became the first north eastern shipbuilder to convert to a public liability company status, with Manchester interests holding most of the shares with Charles Palmer as Chairman and Managing Director.

Between 1866-1873 they built eleven ships for the Gunion Line, their largest ships to be built were the 4,321 grt Montana and Dakota with accommodation for 64-first, 68-second and 1,200 emigrants, on the Liverpool to New York service taking 6 days. Their hull design included tumblehome and it was hoped that they would win the Blue Riband, Both ships were wrecked on Anglesey within thirty four months of each other. Their loss was a relief to the owners, as the ships did not match up with expectations.

An order was received for three pioneering emigrant liners for the Red Star Line’s fortnightly Antwerp to Philadelphia service and the Vaderland (2,748 grt, 2,000 dwt) was the first to be launched in August 1872. They were designed for 70-first class passengers and 800 emigrants, and to carry oil in bulk on the return voyages, but the authorities banned the company from carrying oil as they considered the concept to be too dangerous.

Business was difficult in the 1870s and 1880s with industry in the doldrums worldwide, the era became known as the ‘Long Depression’.

In 1872-73 Two broadside ironclad battleships of 6,640 tons displacement were built. HMS Swifture and HMS Triumph which was launched in September 1870, but in November HMS Triumph was severely damaged by fire, and as a result was not completed until April 1873. The ships were built specifically to serve as flagships on distant stations, primarily with the Pacific squadron.

In 1875, the company built five clippers ships for the New Zealand Shipping Co., for the emigrant and wool trade.

1876 was a very depressed year only saved by The Admiralty ordering twelve 363 ton, shallow draught gunboats for inland waterways. But the output for the year was only 8,635 tons.This was followed by a steady rise leading to a sevenfold increase in tonnage of 61,113 tons in 1883, followed by yet another shipbuilding slump lasting until 1889. Consequently Palmers closed the Willington Quay yard from 1884 until 1888.

George Palmer died in 1879 and in 1886 the shipyards started to use steel for construction and the company also owned the largest graving dock (440x70ft) on the north east coast and a 600 ft patent slipway. Charles Palmer by this time was an M.P. and in 1886 his services in connection with the settlement of the costly dispute between British shipowners and the Suez Canal Company, of which he was then a director, were rewarded with a baronetcy.

The output from the yards were purely dry cargo ships, of increasing size and a constant stream of warship orders and their refits. The company had the highest output of ships of any yard in the UK. Between 1881-1890 the yards built 214 cargo ships and six warships and by 1890 the Jarrow yard had nine shipbuilding berths and Willington Quay six.

The first oil tanker to be built by the Company was in 1887, the 2,875 grt Era for London owners. During World War I she was owned by SA d’Armement, d’Industrie et de Commerce of Belgium, but was captured and sunk in the Black Sea when being used as a Russian Naval transport. Eleven others were built by 1902.

In the 1890s shipbuilding and the general economy was in the doldrums, with orders not forthcoming. In that year the company made a loss of £10,997. Strikes and demarcation disputes were not uncommon in the yards as men struggled with poor health and living conditions, and the constant threat of redundancy if orders failed to materialise.

Accidents and death were a fact of life in these cold, wet, dirty dangerous workplaces. The directors were obliged to pay interest on their preference shares of £5,773 out of the reserve fund, but were unable to pay ordinary shareholders anything. The shares suffered considerable depression in consequence. The directors reported that due to joiners and shipwright strikes deliveries of ships had not been met. They were soon troubled by demarcation disputes between plumbers and engineers. Strikes appeared to be quite common in those days. But the company were on a downward spiral and in 1890/91 they made a loss of £33,0000.

For ship repairs the company used their 600 ft long slipway worked by hydraulic power, while the graving dock is 440 ft long by 70 ft wide did some notable repairs to vessels. The repairs to the oil steamer Rotterdam, built in 1895, returned to the yard in August 1897 and occupied the dock for 137 working days after grounding on the coast of Newfoundland which ripped out most of its bottom shellplating, was one such case.

Sir Charles had been a great philanthropist for his workforce and the town and the people of Jarrow. In 1864, he had the Jarrow Mechanics’ Institute built, designed to give the working men an opportunity to better themselves through education. This contained a library with 6,000 books, reading and billiard rooms and a large public hall. 1870 he paid for a hospital to be built for his employees and their families, and ten years later added a maternity wing.

In October 1893 at the AGM it was revealed that profits for the year were £23,552.

After a good deal of friction within the company at the end of 1893, the Board decided to accept Charles Palmer’s, then aged 71, resignation as chairman and to separate the financial administration from the industrial management of the concern following a series of poor financial returns and the threat of insolvency. With other senior officials also resigning as very considerable economies were put in place.

In 1896 the value of the shares was written down from £35 to £15 each, which permitted a reasonable dividend for the next eleven years, after which the yard sustained heavy losses again.

In 1898 amongst the orders for The Admiralty the Willington Quay yard completed two 3rd class cruisers HMS Pyramus and Pegasus, each armed with eight 4” guns and two 14” torpedoes. In World War I, HMS Pegasus was based at Cape Town to protect shipping in transit via the Cape of Good Hope. She was moored in Zanzibar in September 1914, under repair with her guns out of action, when the German cruiser S.M.S. Konigsberg, appeared on the scene and shelled the defenceless ship which sank in eight minutes. The German ship made a dash to escape retribution and sailed up the Rufiji River, which was then blockaded by the Royal Navy, with the ship being eventually sunk by the Royal Navy. This event became the catalyst for the story and film “The African Queen”!

By 1900, the population had risen to 34,000 and the Willington Quay yard was closed, being sold in 1912. The Jarrow shipyard, with only five building berths produced 30,127grt in 1900. Thereafter there was a gradual slump in orders down until 1908, when only three merchant ships were built. The slump affected builders nationally. From then the trend was reversed up until the outbreak of war. The Company was kept afloat with orders for battleships and destroyers, as the Government matched the Germans in their preparations for war.

The total number of ships built by the end of the century was 691 merchant ships and 51 warships.

The first ship to be launched in the new century was the 7,477 grt passenger cargo ship, Belgia on 14th April for the Hamburg America Line. The owners sold a number of their fleet to The Russian Imperial Navy in 1904 in support of their ill-conceived war with Japan. Belgia was used as a supply ship for the fleet with the name Irtysh. On 27th May 1905, during the Battle of Tsushima, she was damaged and scuttled by her crew the next day.

In August 1901, the British Empire, (9,291 grt/10,500 dwt) was one of three launched for Liverpool owners, for their service, from Antwerp and Liverpool to New York. Initially laid up on the river after completion, The ships were chartered by the Government to carry troops to South Africa for the Boer War. In 1906 they were both sold the Navigazione Generale Italiana of Genoa. The British Empire returned to the red duster when the Cunard line bought her and renamed her Flavia in 1916. On the 24th August 1918 she was sunk by U-107 off Tory Island, en-route from Montreal to Avonmouth. Of the 500 passengers onboard, including 300 Serbian soldiers, 100 cattlemen and 100 crew, only 126 were saved. In the holds there were 750 horses and mules, all of which also drowned.

The ship owner Sir Charles Furness who already owned the Tyneside shipyard, Northumberland Shipbuilding Co. which he bought from Rowland Hodge in 1901, and became chairman. The yard sat directly opposite the Jarrow yard, on the north bank, and half a mile upstream from the Willington yard. Building standard sized tramps which were powered by machinery which came from Richardson, Westgarth & Co., another part of the Furness industrial empire.

In 1902, Sir Charles acquired the interests in the company of the late Sir Charles Mark Palmer and was appointed a director a year later. After he joined the board renovations and modernisation were put in hand. He was a person who was always on the look-out for methods of new technology to improve production and output, overseeing takeovers and the modernisation and transformation of the facilities. In 1910 he was elected Chairman with further plans to extend and consolidate the company.

In February 1904 there were fourteen warships either building or refitting at Jarrow but with the continuing slump in merchant shipping the Company were laying off workmen and becoming more reliant Admiralty orders.Lord Furness foresaw that with war coming the yard would require more building berths, and he set his sights on the failing R. Stephenson’s yard at Hebburn with their seven berths and a larger dry-dock and he acquired the lease in 1904. It was the largest dry dock on the North East coast (700 x 90 ft) with an option to purchase. It was situated two miles upstream and had already been used for docking their battleships.

In 1905 the skyline at Jarrow changed when a gantry system of cableways installed over an area 700 x 150 ft covering two building berths. The installation consisted of overhead lifting and transporting trolleys was supplied by J.M. Henderson & Co. of Aberdeen. The erection of the apparatus created much interest locally owing to its novel appearance, and generated much comment in the technical press of the day. On each cableway there was a trolley carriage, from which hoisting, lowering, longitudinal and cross traversing motions controlled by one man.The electrically powered system had a longitudinal travel of 600 ft per minute, while the transverse speed was 25 ft per minute. The hoist had a 3 ton S.W.L. This system covered every part of the building berth, having collected the various parts from the railway wagons at the end of the berths.

The first notable ship to be built on the berth was the battleship HMS Lord Nelson of 17,820 ton (displacement) in May 1905.

Sir Charles Palmer died in June 1907 (aged 85).

In 1908 Palmers employed 7,500 men and the town had grown, with housing for 70,000 people.

In May 1909 the company received an order for the largest warship to be built at the yard, the 26,500 ton (displacement) battle cruiser HMS Queen Mary (above) which was laid down in March 1911. The ship sailed from the Tyne on 30th August 1913 and joined Admiral Beatty’s Grand Fleet. In the confusion of war she was lost in May 1916 at Jutland, when a German salvo pierced the un-armoured deck plating and blew up in the magazine, with only nine crew surviving out of a crew of 1,275 Officers and men.

In 1910 the new Chairman, Lord Furness, expanded the business and laid out large sums of money for extensions and new machinery and in 1911 the seven berth Robert Stephenson shipyard with a 715 ft dry-dock was leased and bought a year later, establishing Palmers Hebburn Co. Ltd. In the same process the Willington quay yard was sold.

In 1912, following the reluctance of the shareholders to contribute further capital to the company the £1 shares fell to about 3/-. Lord Furness whose health was failing resigned, and in the same year the national coal strike cost the company £30,000 and caused considerable disruption to the steel mills.

During World War I, the shipyards were extremely busy, building all manner of warships from battleships to submarines while the repair departments were struggled to cope with the volume of work. In June 1914 Palmers were building one battle cruiser, two light cruisers and 12 torpedo boat destroyers.

With the Rosyth Dockyard was still under construction, The Admiralty had a problem as there were no repair facilities for the Royal Navy between Scapa Flow and the English Channel bases.

So the large Medway Admiralty Floating Dock No. 4, with a lifting capacity of 32,000 tons, which had been built by Swan Hunter & Wigham Richardson Co. Ltd. in 1912 , was moored in Jarrow Slake between June 1915 and November 1923, and placed under the management of Palmers. Prior to its arrival over 1.5 million tons of the river bed had to be excavated to allow for the ballasting down of the dock.

The Admiralty needed repair facilities within easy reach for any damaged ships from the North Sea. One hundred and forty five warships were repaired including Admiral Beatty’s flagship HMS Lion after Jutland, and five American battleships in 1918.

At the Jarrow and Hebburn dry docks another 347 ships were repaired.

On the night of 15th June 1915 the shipyard was bombed in a German Zeppelin raid on Tyneside, aimed at destroying the shipyards. The bombs hit the fitting shop and coppersmiths workshops resulting in the deaths of twelve of the workforce.

Palmers contribution to the Royal Navy’s World War I effort included three more battleships Lord Nelson, Hercules and Resolution, the battle cruiser Queen Mary, three monitors, eleven cruisers, forty eight torpedo boat destroyers and two submarines.

The shipyards were still completing war time orders until 1921 and with the acquisition of the Stephenson yard Palmers now had twelve berths to keep busy. This proved difficult, as owners bought second hand standard ‘War’ type vessels and the surrendered units of the German merchant fleet instead.

After the war Palmers’ management had plans for a large modernisation of the two yards, but these were abandoned when another slump started in the 1920s and the industry remained in the doldrums for the rest of the decade with poor profit margins. The steel works closed in 1921, opening again briefly in 1923 before closing completely by 1927.

In 1923 a large cable laying ship was built for Siemens Brothers of London. Nine others had been built or converted in the nineteenth century for various companies for this business. The Faraday (above) had a capacity of 91,000 cubic feet of coiling space in her four cable tanks. She worked worldwide either for Siemens or on charter. As HMS Faraday she was bombed and sunk by a Heinkel III, on 26th March 1941 when on passage from Falmouth to Milford Haven.

After the war the output concentrated on oil tankers and dry cargo ships with over fifty being built between 1921 and 1930. One of these was Blue Funnel’s 7,628grt/1922 built Automedon (above) which was at the centre of a major blunder by the War Cabinet’s Planning Division, which cost thousands of lives. On 14th November 1940 when on passage near Sumatra, it was spotted by the German commerce raider Atlantis, which opened fire and killed everyone on the bridge and destroyed much of the superstructure. A German boarding party discovered 15 bags of Top Secret Mail bound for the C. in C. of British Far East Command which detailed the strength details of Singapore’s defences, and the status of the Military and Naval forces based there. Consequently the Germans handed over copies to Japan, which in turn led to the invasion and fall of Singapore in February 1942. Surely, such dispatches should have gone via the Royal Navy!

In October 1928 two of Palmer’s ships collided off the Nore Lightship. Those involved were the Hebburn built San Gerardo (12,915 grt/1922 built), one of eight ships built for the Eagle Oil Transport Co. and the Jarrow built City of Lancaster (2,996 grt/built 1924), which went ashore on the Kent coast, before being towed back to Jarrow for repairs.

Poor trading conditions for the world’s fleets followed by the Wall Street crash and a considerable trading loss in 1930 sounded the death knell for the company as they posted a loss of over £5.5 million at today’s rates.

In 1930 two Jarrow built tankers from 1918 for the Anglo-American Oil Co., the Cadillac and Sararnac, came back to Palmers drydocks to have 350 foot midship cargo sections replaced. The deterioration in the steel was caused by the highly corrosive oil cargoes the ships had been carrying, in the days before the anti-corrosive paint applications we have today.

In April 1930 one of the last ships to be built, at Palmers Hebburn Co. Ltd. was claimed to be the largest refrigerated vessel afloat, with 659,600 cubic feet of refrigerated insulated holds with a 12,000 dwt capacity. The Tuscan Star (above) was also the first motor ship built for the Blue Star Line. In September 1942 she was lost when sunk by U-109 off Monrovia , when homeward bound from Buenos Aires with the loss of 51 crew members.

At the beginning of 1931 there were 8,405,000 grt tons of shipping laid up worldwide, 885,000 tons (653 ships) in UK ports with 108 laid up in the Tyne of 194,949 tons.

In 1931, the company recorded a loss of £88,867 and was given an extension of credit, but the writing was on the wall.

In a last attempt to stave off the inevitable The Admiralty awarded a contract for two ‘D’ class destroyers and HMS Duchess (yard No. 1007) was launched on 19th July 1932 and completed on 27th January 1933. Since 1900, 183 merchant ships had been built by Palmers of 989,479 grt and 53 warships of 171,426 tons displacement.

In 1930 there were 684 berths in the country and a further 116 were purchased by National Shipbuilders Security Ltd. whose policy was to secure as far as possible a balanced reduction of facilities for the varying types of shipyard work, properly apportioned throughout the shipbuilding areas.

The complete closure of the shipyard, engine works, blast furnaces and steel mill happened at the end of 1933.

So another iconic shipbuilding company shut it’s gates for the last time, which had a devastating effect on the town leading to destitution and despair for thousands in Tyneside.

Comments

Sorry, comments are closed for this item