Ports of Jersey Limited is the incorporated business that operates the Channel Island of Jersey’s Airport and Harbours, providing the necessary infrastructure for these vital facilities to function.

The authority’s role is to continue to develop the facilities, services and products for the benefit of residents, visitors and businesses as well as to undertake a number of public service obligations on behalf of the Island’s government, including Jersey Coastguard and Historic Harbours. Since the incorporation of Ports of Jersey Ltd. in October 2015, and each year since, the authority provides the equivalent of £500k of community benefit by supporting local clubs and societies, raising money for local charities, supporting Jersey events and continuing the educational programmes on sea safety.

Ports of Jersey Ltd. operates 4 brands, namely Jersey Airport, Jersey Harbours, Jersey Marinas and Jersey Coastguard. One of the maritime sectors is Marine Services, which undertakes an array of such services throughout the UK and Europe, with the benefit of being in a prime location, providing world class services. These services include Bed Levelling and Dredge Support, Engineering and Project Management, Hydrographic Services, Mooring, Maintenance and Anchor Handling, Renewable Energy Support, ROV, Survey and Dive Support, Salvage and Towing/Pushing.

In 2005 the 212gt Duke of Normandy, a 26m long Damen Shoalbuster 2609 became Marine Services’ flagship, undertaking the aforementioned maritime duties across Northern Europe. Being part of the Damen Shoalbuster family, the Duke of Normandy has an 8m wide bed levelling plough which is rigged and levelled with the use of cable counters. This can be used either as a standalone operation or in support of maintenance dredge operations, and can be validated by in-house MBES surveys. The vessel is also an ideal platform for commercial dive teams, with space on deck for a dive control centre in a specialised container which has power, light and heating. The 18m outreach and 12 tonnes capacity deck crane also offers an engineering, infrastructure and salvage support role, along with a shallow draught and precise manoeuvrability. A large crane capability and A-frame rig allows for the safe deployment of a range of sub-sea survey instruments and a 26 tonnes bollard pull fulfils coastal towage services.

Fleet Expansion

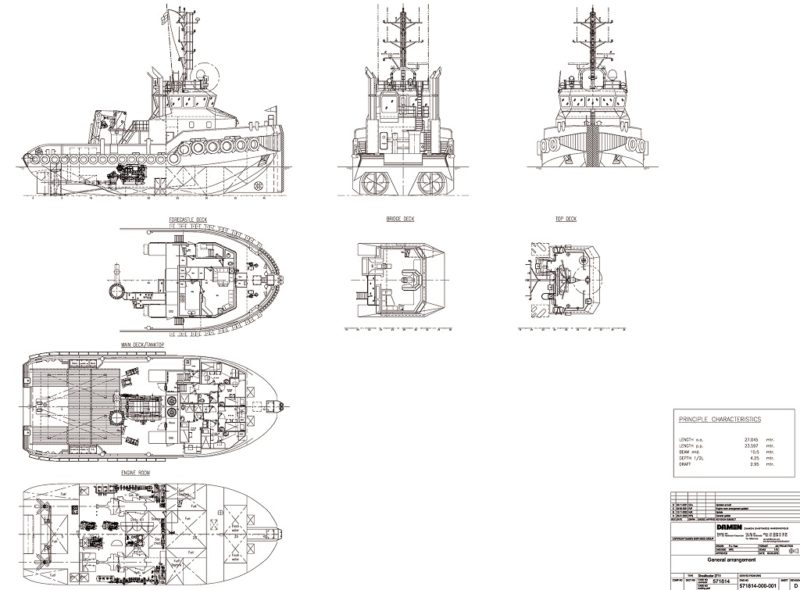

Such had been the success of the then 15-year-old Duke of Normandy that a sister vessel was sought, culminating in the signing of a contract with Damen Shipyards Group, as announced on 1st February 2021, for a Damen Shoalbuster 2711, the second vessel of her specific type ever to be built.

In the early years the Duke of Normandy was kept occupied around the waters of her home island, carrying out normal harbour tasks like ploughing, maintaining Aids to Navigation and assisting ferries during bad weather. But, since Ports of Jersey became a Private Limited Company in 2015 options were explored regarding chartering her out, which proved to be very successful, hence the expansion. The award of the contract followed a tender procedure during which Ports of Jersey Ltd. was looking for a vessel offering versatility to equal or surpass that of the Shoalbuster 2609 to maintain its presence in the commercial maritime world that had been developed over the previous 6 years, both locally and further afield. By this time, Ports of Jersey Ltd. also had a keen focus on sustainability so it was their goal to support forthcoming offshore wind projects that will take place in UK and EU waters nearby. The Damen Shoalbuster 2711 was selected after representatives visited the very first of this new class of Shoalbuster on display at the Seawork Exhibition in Southampton. The 2711 is an evolved version of the 2609, featuring an additional 2 metres of beam to provide extra stability, work space, storage and space for a larger crane. As with all standard Damen vessels, the Client can select their own options to suit their individual requirements, so Ports of Jersey Ltd. specified the latest Heila crane based on the performance of and familiarity with the Heila equipment aboard the Duke of Normandy. In fact, the operation of the 2005-built 2609 effectively sealed the deal for the 2711 newbuild, along with a competitive price. The present Shoalbuster family also includes the 2308, 2609, 2709 ICE, 3209, 3311, 3612 and 3815 SD. The first 2 digits relate to the length in metres and the second 2 digits refer to the beam of the vessel in metres. The prefixes SD and ICE are shallow draught and ice-class variants. Damen had also cultivated a good working relationship with Ports of Jersey Ltd., which included Damen Shipyards Gorinchem winning the tender to conduct the Duke of Normandy’s 15-year drydock and renewal survey. This process proved a little more complicated than expected as, no sooner had the vessel docked than the coronavirus outbreak occurred. The crew had to leave The Netherlands and return to Jersey until the situation eased again. From that moment onwards the project was managed remotely with Damen’s support.

The Duke gets a Duchess

Damen Shipyards Group can provide newbuilds quickly via their routine of keeping examples of certain vessels in stock having been prefabricated elsewhere and generally fitted out once shipped to The Netherlands. The Jersey contract was one such example with the basic shell of the vessel having had her keel laid on 18th June 2020 before being completed and lowered into the water at the Safe Shipyard in Gdansk, Poland around New Year 2020/21. YouTube footage uploaded on 3rd January 2021 duly showed the vessel getting her bottom wet. The Shoalbuster 2711 was then shipped to Damen Shipyards Gorinchem for fitting out and completion ahead of being launched as a finished vessel on 27th September 2021. Safe Shipyard has operated commercially since 1995, with locations in both Gdansk and Gdynia, including on the site of the former Gdańsk Shipyard. The prefabrication and assembly of hulls, anti-corrosion works on new-built and repaired ships are specialities with other clients including Chantiers Piriou, Chantiers de la Haute Seine, Larsnes Shipyard (Norway), Karstensen Shipyard in Denmark and Sietas in Germany. The Damen Shipyards Group features regularly in the Newbuild series thanks to their impressive array of vessel types and willingness to assist with feature information. The Damen story began with brothers Jan and Rien Damen opening a small yard on the River Merwede in Hardinxveld, The Netherlands in 1927. By the end of the 1930s, though still a small concern, Damen was nonetheless successful and had delivered its 100th vessel.

The second generation began in 1969 when Kommer Damen took over the company with a new vision of standardised shipbuilding and the HQ moved down the river from Hardinxveld to Gorinchem.

From 1978 Damen began to construct vessels outside The Netherlands and expanding, acquiring De Groot (1988), Amels (1992) and Royal Schelde (2000) and entering the dredging, yachting and naval markets. The Sea Axe Bow revolution began in 2006 and, in 2020, Arnout Damen, son of Kommer, became CEO. Arnout’s appointment came at an exciting time for the company as it aligned towards the future with a focus on sustainability, digitalisation and operational excellence. Following completion and sea trials, the new Shoalbuster 2711 was transferred to Damen Shipyards Hardinxveld on 10th November 2021 and christened there as Duchess the next day. During the ceremony the newbuild was officially named by Ports of Jersey Limited employee Fiona Planterose. The Duchess was formally handed over to Ports of Jersey Ltd. at Damen Shipyards Hardinxveld on 12th November 2021 before setting off for Le Havre to undertake her first revenue earning job two days later. The Duchess is 27.02m long overall with a beam of 10.50m, a hull depth of 4.25m and a minimum/maximum draught of 2.80/3.00m. This particular example of the Shoalbuster family was first introduced in 2019 with the prototype being EMS Offshore Service GmbH & Co. KG’s 320gt/2019-built EMS Tug, with a notably greater gross tonnage than the 193gt of her younger sister. The 2711’s beam is increased by 2 metres compared to similar Shoalbuster models and this provides multiple benefits including space for 7 crewmembers instead of 6, increased stability (permitting additional crane lifting capacity) plus increases in cargo deadweight and bollard pull. Despite the robust and purposeful “large vessel” character, the 2711 is also still within the 24m load line length, a key point for operators working in U.K. waters or out of U.K. ports. This multipurpose, shallow draught workboat is defined by a heavy-duty construction and large work deck as well as a broad scope of towing/anchor handling equipment. A bollard pull of 43 tonnes establishes the Duchess’ towage credentials with the power being provided by a pair of Caterpillar 3512C HD DITA 12-cylinder main engines with a power output of 2,610kW/3,546 HP at 1600 rpm.

Propulsion is via two 2.25m diameter/248rpm screw propellers in nozzles with the maximum service speed being 11 knots. A 200bhp Veth electrically driven bow thruster is also installed plus two 107kVa Caterpillar C-4.4 TA auxiliary engines and one 375 kVA Caterpillar C9.3 generator for the deck equipment. Aft of the deck house is the unobstructed 75m2 working deck with a cargo capacity of two TEU and a deckload of 15 tonnes per m2. The carrying capacity deadweight is 120 tonnes. Located forward of the clear deck area is a Heila HLRM 140-6S electro-hydraulic knuckle boom crane with a maximum lift capacity of 5.65 tonnes at an outreach of 19.03m and 19.70 tonnes at an outreach of 6.28m. Other deck equipment includes a double drum winch of 100 tonnes (pull), a 12 tonnes capacity tugger winch and hydraulic coupling winches for pushing mode. All deck equipment operates on biodegradable lubricant oil.

Other equipment includes an integrated moonpull located within the push bow and a 135 SWL stern roller. The stern can also accommodate an optional 30 tonnes SWL A-Frame for seabed ploughing, survey work, dive support roles etc. The forward mounted superstructure caters for the crew and navigational needs on three levels. The main deck level houses the sleeping quarters for the crew, Chief Engineer and Captain. Above on the Forecastle Deck can be found the Messroom, Galley and Stores with the third level above being the Navigation Bridge with 360-degree visibility.

Team Work

At the time of writing both the Duke of Normandy and Duchess were engaged in dredge support duties on the south coast. The Duchess departed from Liverpool on 10th January with the Boskalis backhoe dredger Odin in tow, arriving at Southampton’s eastern docks 4 days later. Spoil barge 1002 arrived the next day under tow by Holyhead Towage’s 131gt/2009-built Afon Wen with spoil barge 1001 arriving behind the Duke of Normandy that afternoon, having departed Liverpool on 12th January. Boskalis’ 330gt/2012-built Terramare 1 arrived the following day with another spoil hopper barge and the dredge barge Odin was moved into position adjacent to Southampton’s Container Port. The equipment was all present for a 5-week project to dredge the container berths. This dredging project was part of a £40 million investment programme announced in April 2021 to make improvements the DP World container terminal so as to take the port to the next level as a premier international freight and logistics hub. The facility’s new infrastructure investment includes the dredging/widening of berths to continue to accommodate the world’s biggest ships, a £10 million investment in a new class of 11 hybrid straddle carriers, a planned £3 million investment in the redevelopment of the yard for the storage and delivery of customers’ empty containers, thereby increasing capacity by 25% and the extension of a quay crane rail by 120m to ensure that the world’s largest container cranes can service all berths at the terminal, accompanied by the relocation or decommissioning of other quay cranes. The improvements to the container terminal were also expected to ease the congestion that Southampton, like many ports around the world, has been experiencing as the world tries to catch up from the effects of the pandemic, exacerbated in the UK’s case by the need for greater paperwork and inspections following Brexit.

Comments

Sorry, comments are closed for this item