On 6th March 2014 a contract was signed by vehicle shipment specialist UECC with Kawasaki Heavy Industries (KHI) for two new vessels to be constructed at the NACKS shipyard in Nantong, China which is a joint venture between KHI and China Ocean Shipping (Group) Company. Deliveries of both the vessels were scheduled for the second half of 2016. The 181m long and 30m beam ships were designed with 1A super Finnish/Swedish ice class, facilitating year round trading in the Baltic area with the vehicle deck configuration optimised for both present and predicted future cargo mix. The duo also became the first Pure Car & Truck Carriers (PCTCs) in the world capable of operating with LNG fuel or heavy fuel oil and marine gas oil, providing greater flexibility and efficiency. An LNG fuel propulsion system had not previously been installed in such a vessel and the new ships would be able to complete a fourteen day round voyage in the Baltic using solely LNG fuel, including main engine and auxiliary power generation. LNG (Liquid Natural Gas) is of course recognised as the cleanest and most environmentally friendly choice of fuel suitable for marine transport with the cruise and ferry sectors already embracing this eco-friendly technology. The choice of LNG as a fuel significantly reduces CO2 and NOx emissions, as well as almost eliminating Sulphur Oxide and particulate emissions.

E for Eco

UECC has a tradition of inviting employees to name the company’s new vessels. This proves to be a highly popular process and especially so when it came to naming the two new LNG vessels.

All employees were given the chance to submit their ideas, which were subject to certain criteria. Suggested names needed to start with “Auto” and end with a word that reflected the green/environmental profile of LNG fuel. A team of UECC judges then compiled a short list of the best suggestions. All employees were given the opportunity to vote for their favourite two names in the short list during Round Two of the process. The names receiving the most votes were to be given to the new vessels. In total, 66 UECC employees took part during the 30 day period for names to be submitted and 597 names were suggested. Ten names went forward for the final voting, 54 UECC employees voted and 109 votes were gathered. The two most popular choices were Auto Eco and Auto Energy (in that order) so the newbuilds had their identities. Collectively the new LNG powered class of ships are known as the E-Class. UECC (United European Car Carriers) was founded in 1990 and is jointly owned by Nippon Yusen Kabushiki Kaisha (NYK) and Wallenius Lines. The head office is located in Oslo, Norway, with eight offices and four port related terminals situated across Europe. UECC operates a fleet of 18 pure car and truck carriers (PCTC) that are designed to meet the necessary flexibility and efficiency requirements of the short sea market. The company’s aim is to be the leading short sea ro-ro operator in Europe. Matching the Operator’s initials, the company values are Unity, Energy, Challenging and Commitment. In total there are 353 employees, 112 shore based and 241 sea going personnel aboard the UECC owned ships.

The 18-strong fleet consists of the two new E-Class ships, three S-Class (AutoSky/Star/Sun), four P-Class (AutoPrestige/Premier/ Pride/Progress), four Breeze Class (Aegean/Arabian/Asian/ Baltic Breeze) and 5 Leader Class (NYK) ships (Coral/Emerald/ Opal/Vega/Victory Leader). Around 1.7 million units are shipped annually and UECC’s network consists of the following:

Baltic: Southampton-Zeebrugge-Bremerhaven-Malmo-Hanko- St. Petersburg-Southampton weekly with Gdynia served every two weeks. Two E Class ships are deployed; Norway: Bremerhaven-Oslo-Drammen-Bremerhaven-Oslo using a P-Class ship twice weekly;

North Sea: Cuxhaven-Immingham-Cuxhaven-Immingham using a P-Class ship twice weekly;

Biscay: Santander-Pasajes-Zeebrugge-Southampton using an S-Class ship weekly; Santander-Pasajes-Rotterdam-Zeebrugge using an S-Class ship weekly and Pasajes-Zeebrugge- Southampton-Le Havre using a P-Class ship weekly; Pasajes- Portbury using an S-Class ship weekly;

Atlantic: Vigo-Le Havre-Zeebrugge-Sheerness every eight days using a Breeze Class ship; Vigo-Zeebrugge-Bremerhaven- Drammen-Wallhamn-Cuxhaven-Southampton weekly using two Breeze Class ships; North-South: Autoport-(Yenikoy)-Borusan- Vigo-(Southampton)-Bremerhaven-(Vlissingen)-Zeebrugge- Portbury-Vigo-Sagunto-Tarragona-Livorno-Piraeus with weekly calls using 5 Leader Class ships.

Driving Forward

On 6th August 2015 the project took a major step forward when the formal steel cutting ceremony for the first of the two vessels, the Auto Eco, took place at the NACKS shipyard in Nantong, China. The ceremony was attended by Mr. Masataka Ishino/Bank of Tokyo Mitsubishi, Mr. Takashi Yonesawa/NYK Planning Team/Technical Group, Mr. Peter Anderson/UECC New Building Project Manager, Mr. Glenn Edvardsen/UECC CEO, Mr. Han Chengmin/NACKS President, Mr. Thomas Thue/UECC CFO, Mr. Carl Fagergren/Wallenius Marine Project Manager of Strategic Projects, Mr. Akira Ryu/Bank of Tokyo Mitsubishi, Mr. Jim Smith/Lloyds North Asia Marine Manager and Mr. Masanori Mizuno/NACKS, President. The keel laying ceremony for the same vessel followed on 14th December 2015 and launching took place on 14th April 2016. The keel laying and launch of the Auto Energy took place on 15th December 2015 and 30th June 2016 respectively. The birthplace for the new ships, Nantong COSCO KHI Ship Engineering Co., Ltd. (NACKS) shipyard in Nantong, China, is a large-scale shipbuilding joint venture between China COSCO Shipping Corporation Limited and Kawasaki Heavy Industries Ltd. (KHI). NACKS mainly engages in the construction of various kinds of bulk carriers, 150,000dwt to 300,000dwt oil tankers, super-panamax container ships and large-scale car carriers plus Special Ships, LNG carriers etc. NACKS was founded in 1999 and has completed a remarkable array of ships since that time, setting several new records in Chinese shipbuilding industry in terms of ship type, its steel use ratio, power consumption per $10,000 of output value plus other economic and technical achievements. The Auto Eco (built as Kawasaki hull no. 8019/NACKS hull no. NE212) was delivered to UECC by Kawasaki Heavy Industries Ltd. on 29th September 2016.

Kawasaki is focusing on the building of a wide array of ships that run primarily on LNG in response to the predicted rise in global demand for LNG-fuelled vessels. In addition to transport vessel construction, the company plans to build LNG supply ships and also take advantage of the synergy achieved through co-ordinated application of the wide range of LNGrelated technologies possessed by the Kawasaki Group in order to establish the supply chains necessary for the transition to widespread LNG fuel dissemination. All of these measures are part of active efforts toward making LNG a primary fuel source throughout the commercial shipping industry. The EClass vessels employ a number of other design elements and technologies to help reduce fuel consumption and emissions, ensuring safer and more efficient operations. With capacity for approximately 3,985 cars, the two ships are the largest PCTC type vessels specifically designed for transitting the Baltic and other ice prone areas. The vessels have been jointly developed by UECC, Wallenius Marine and NYK Technical Group, together with Kawasaki Heavy Industry in Japan. The second vessel, the Auto Energy (built as Kawasaki hull no. 8020/NACKS hull no. NE213) was delivered to UECC by Kawasaki Heavy Industries Ltd. on 29th November 2016.

The world’s first dual fuel LNG PCTC, the Auto Eco, had her formal Naming Ceremony at the Port of Zeebrugge, Belgium on 21st November 2016 whilst under the command of Captain Henryk. The ship’s Godmother was Mrs. Claire Tillekaerts, CEO of Flanders Investment & Trade. The event was also attended by Mr. Geert Bourgeois, the Minister- President of the Government of Flanders, Flemish Minister for Foreign Policy and Immovable Heritage not to mention the Secretary of State for the Belgian North Sea Coast (Mr. Philippe De Backer), Mayor of Brugge (Mr. Reneet Landuyt), Norwegian Ambassador to Belgium (Mrs. Ingrid Schulerud), Japanese Ambassador to Belgium (Mr. Masafumi Ishii) and representative from the Port of Zeebrugge (Mr. Joachim Coens/President & Managing Director). Zeebrugge is the largest car handling port in the world. In 2015 a total volume of 2.4 million new cars was handled and in 2016 the total volume was an estimated 2.8 million units. In addition Zeebrugge constitutes an authoritative LNG hub following 30 years of experience of the LNG terminal of Fluxys Belgium in the outer port. The Auto Energy, forever to be known as “sister vessel to the world’s first LNG-powered PCTC Auto Eco,” was christened at the Port of Malmö, Sweden on 7th February 2017. Coinciding with a rare heavy snowfall that had not happened in Malmö for many years, Bjorn Svenningsen (Head of Sales & Marketing/UECC) was the Master of Ceremony once again and he welcomed the guests with an introduction to the history of naming ceremonies held in Malmö. The ship’s Godmother was Mrs. Eva Kleberg, wife of Mr. Jonas Kleberg (Owner and Chairman of Wallenius Lines). Also in attendance were Mrs. Katrin Stjernfeldt Jammeh, the Mayor of Malmö, plus Dr. Cleopatra Doumbia-Henry (President of the World Maritime University), Mr. Johan Röstin (CEO of Copenhagen Malmö Port) and Mr. Takao Kusakari (Senior Advisor of NYK Line).

Blue & Green

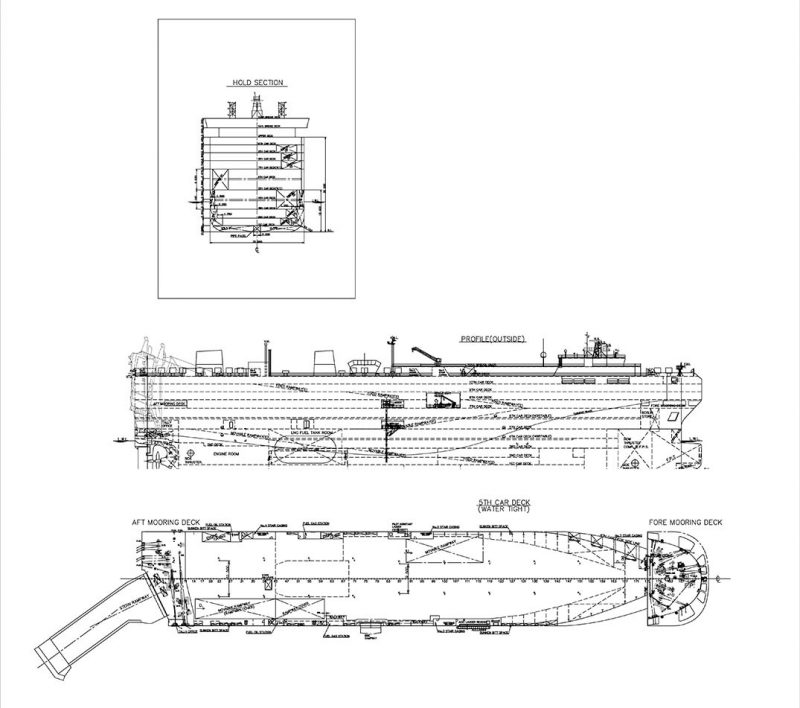

The two ships may carry the trademark blue colour scheme of UECC but they are most definitely green on the inside. The 42,424gt and 181m long E-Class sisterships offer a beam of 30m and a hull depth of 30.22m. Each vessel has a summer draught of 9.60m, deadweight of 16,995dwt and a length between perpendiculars of 170.50m. The bow and hull is 1A super Finnish/Swedish ice classed to tackle whatever the Baltic Sea presents her with plus the slender bow profile also provides minimal resistance as the ship cuts through the water. The choice of propulsion machinery was dictated by the need to efficiently comply with the strict environmental criteria governing operation in emission control area (ECA) waters, as UECC’s new tonnage serves the Baltic and North Sea regions. The MAN B&W 8S50ME C8.2 ME-GI 12 dual-fuel, two-stroke main engine affords the flexibility to sail on heavy fuel oil (HFO), marine gas oil (MGO), or LNG. Produced under licence by Kawasaki, the ME-GI machinery has a maximum output of 11,000kW at 113rpm and uses high-pressure fuel gas injection technology. The normal engine output, at 80% MCO, is 8,800kW at 105rpm. The auxiliary engines for electrical power generation are also of a dual-fuel type, from the Wartsila range. These consist of one 900kW, 450 V, 60 Hz @ 1200 rpm unit and two 1400 kW, 450 V, 60 Hz @ 1200 rpm units. With a 760m3 LNG fuel tank manufactured by German cryogenic system specialist TGE Marine positioned forward of the engine room but aft of Decks 1-4, the Auto Eco and Auto Energy have the capability to fulfil a typical 14-day Baltic round voyage operating solely on LNG. UECC has contracted for LNG to be supplied to the new vessels in the port of Zeebrugge using a dedicated LNG bunkering tanker.

Engie, its parent company Fluxys, Mitsubishi Corporation, and NYK has taken delivery of the world’s first purpose built liquefied natural gas bunkering vessel (LBV) from Hanjin Heavy Industries & Construction Co. Ltd., at the Yeongdo shipyard in Busan, Korea. On her delivery voyage from Korea to Zeebrugge the 7,403gt Engie Zeebrugge ran on LNG that was loaded by trucks prior to departure from the shipyard, a loading process that took some days to be completed. The ship arrived at Zeebrugge on 1st April and, with a 5,000m3 LNG capacity, will supply LNG as a marine fuel to ships operating in Northern Europe. The Engie Zeebrugge marks a milestone in the development of the European LNG bunkering chain and, while LNGfuelled ships up to now have been largely dependent on fixed bunker locations or the limited bunkering capacity of LNG trailers, the Engie Zeebrugge can take the LNG to the ships and therefore hugely improve the flexibility of the fuel’s use. Compared with heavy fuel oil firing, use of LNG as the main engine’s fuel source can cut carbon dioxide (CO2) emissions by 23%, nitrogen oxide (NOx) emissions by 13%, sulphur oxide (SOx) emissions by 92% and particulate matter (PM) emissions by 37%. Furthermore, the adoption of LNG as fuel enables the fulfilment of Energy Efficiency Design Index (EEDI) Phase 3 standards. For use as a fuel the LNG is cooled to -160 degrees Celsius, forming a liquid 600 times smaller in volume than in gas form. The gas supplied to UECC will still be in liquid form, kept under pressure on the Bunker Vessel. The LNG is transferred from the Bunker Vessel to the ship and stored directly in a highpressured tank. When reverted to gas the LNG is compressed in the engine and then ignited using Marine Gas Oil as a ‘pilot fuel’. A single KHI 4-bladed, skewed-type Controllable Pitch Propeller with a diameter of 6,300mm pushes each ship through the water to produce an optimised (most efficient) service speed of 16.5 knots whilst the design speed is 18.6 knots.

Manoeuvrability in port is assisted by a KHI 1,500kW and 2,200mm diameter transverse tunnel thruster at the bow and a KHI 800kW and 1,650mm diameter transverse tunnel thruster at the stern. Both are equipped with 4-bladed skew type propellers. On the top deck, port side, can be found two slender funnels, one for the main engine and one for the auxiliaries. The deck furniture that immediately sets the LNG ships apart from their counterparts is the trestle style structure between the two funnels that supports the vent pipes for the LNG system. The maximum cargo capacity for the E-Class is stated as 4,000 cars (RT43) but the general capacity is listed as 3,985 cars. The 10-deck configuration provides for 6,000m2 of ‘high and heavy’ cargo and a maximum weight for an individual piece of cargo of 160 tonnes, catering for a broad mix of vehicles, machinery, and wheel borne freight. The arrangements also take account of evolving and predicted traffic developments and market requirements. Overall the car deck area per ship is 32,000m2.

The vehicle decks are accessed via the traditional large, 22.7m long hinged ramp on the starboard aft quarter. The ramp serves an opening at Deck 5 level that is 15m wide and 5.7m high. The safe working load (SWL) is 160t. A secondary side ramp located amidships on the starboard side with a 30t SWL serves a 6.5m wide access door. The internal decks are linked by a system of ramps with Decks 3/2/1 served via a movable hydraulic ramp from the starboard side of Deck 5 whilst another such ramp links Deck 5 with Deck 7 on the port side. As can be seen from the data panel, the clear heights on the decks range from 1.85m (Decks 1 & 10) to 5.30m on Deck 5. Decks 4 and 6 are hoistable so can be placed at respective heights of 2.00m/1.70m and 2.20m/1.90m or stowed away altogether to provide space for the largest/heaviest loads on Decks 3 & 5. Deck Loads vary from 2.15kN/m2 to 24.5kN/m2 whilst the axle load is generally 15.6kN/axle except 196kN/axle on Deck 3 and 490kN/axle on Deck 5. Vehicles loaded with dangerous substances or cargo can be secured on the boarding deck (Deck 5) for shipment. The crew of 19 is accommodated on the uppermost deck, Deck 11, in a block located forward beneath the navigation bridge. The crew facilities include 7 Officers cabins, 18 crew cabins including the Cook, 6 cabins for drivers, 5 spare cabins and 1 pilot cabin. The accommodation block also includes a Common Mess Room, Common TV-room, Lobby, Mess Room for Drivers and a Gymnasium.

On 27th February UECC announced the deployment of the Auto Eco and Auto Energy on the weekly Baltic Service, which also now includes the Swedish port of Malmö in the loop, hence the naming ceremony for the Auto Energy being held there. The Baltic loop has a weekly frequency and serves Southampton-Zeebrugge-Bremerhaven-Malmo-Hanko-St. Petersburg-Gdynia (every two weeks)-Southampton. UECC is rightly delighted with its new vessels and has even boldly stated that “you can count on them 365 days a year!” Mechanical gremlins permitting, this must surely be an accurate expectation of such workhorses.

Signifying a further stage in the uptake of LNG fuel technology by the vehicle carrier sector, Volkswagen Group Logistics announced a charter commitment to a pair of PCTCs planned by the Norwegian company, Siem Car Carriers. Two newbuildings, each with capacity for about 4,500 vehicles, are to be phased into traffic between North America and Europe from 2019 onwards. In each case, the main engine will be a 12,600kW dual-fuel unit developed by MAN Diesel & Turbo, which is majority-owned by Volkswagen.

Special thanks must go to Bjorn O. Gran Svenningsen, Head of Sales & Marketing, UECC, Oslo and Evie Khoo, Sales & Marketing Co-ordinator, UECC, Oslo

Specifications

| Ordered | 6th March 2014 |

| Keel Laying | 14th December 2015 (Auto Eco)/ 15th December 2015 |

| Launched | 14th April 2016 (Auto Eco)/30th June 2016 (Auto Energy) |

| Delivered | 29th September (Auto Eco)/29th November 2016 (Auto Energy) |

| Yard No | 8019/20 (Kawasaki) – NE212/213 (NACKS) |

| Shipyard | Nantong COSCO KHI Ship Engineering Co., Ltd. (NACKS) |

| Location | Nantong, China |

| Class | Lloyd’s Register of Shipping |

| Class Notations | +100A1, Vehicle Carrier, Movable Decks Ice Class 1AS FS, +IWS, LI, +LMC, UMS, NAV1, IBS, GF, SCM |

| Port of Registry | Funchal, Madeira |

| IMO | 9736365 & 9736377 |

| Registered Owner | UECC IoM Ltd. c/o United European Car Carriers Unipessoal Lda, Sala 212, 2 andar, Avenida Arriaga 73, 9000-060 Funchal, Madeira. |

| Registered Manager | UECC Unipessoal LDA, Sala 212, 2 andar, Avenida Arriaga 73, 9000-060 Funchal, Madeira. |

| Length overall | 181.00m |

| Length bp | 170.50m |

| Moulded Breadth | 30.00m |

| Moulded Hull Depth | 30.22m |

| Summer Draught | 9.60m |

| Design Draught Moulded | 8.40m |

| Gross Tonnage | 42,424 |

| Deadweight Tonnage | 16,995 |

| Deadweight @ Design Draught | 12,182 |

| Deadweight @ Summer Draught | 16,582 |

| Optimised Speed | 16.5 knots |

| Design Speed | 18.6 knots |

| Ice Class | Finnish-Swedish Ice Class 1A Super |

| Total Car Capacity | 3,985 cars |

| Total Vehicle Decks | 10 |

| Main engine | MAN B&W 8S50ME C8.2 ME-GI 12 |

| Maximum Continuous Output | 11,100 kW @ 113rpm |

| Normal Output (80% MCO): 8800 kW @ 105rpm | |

| Auxiliary Generators | 1x 900kW, 450 V, 60 Hz @ 1200 rpm and 2x 1400kW, 450 V, 60 Hz @ 1200 rpm |

| Propeller | 1x KHI 6300mm diameter Controllable Pitch Propeller(CPP) Four blades, skewed type |

| LNG Tank | 760m3 capacity |

| Endurance | 8,800nm on fuel oil / 4,600nm on LNG |

| Bow Thruster | 1 x KHI 1,500kW 4-blade skew type, 2200mm diameter |

| Stern Thruster | 1 x KHI 800kW 4-blade skew type, 1650mm diameter |

| Stern Ramp | 22.7m long x 15m wide. SWL 160t |

| Stern Access | 5.7m Clear Height |

| Side Ramp | 30t SWL |

| Side Access | 6.5m wide |

| Crew Complement | 19 Officers & Crew |

Deck Particulars:

| Deck No. | Height (m) | Deck Load (kN/m2) | Axle Load (kN/axle) |

| 10 | 1.85 | 2.45 | 15.6 |

| 9 | 2 2 | 45 | 15.6 |

| 8 | 2 | 2.45 | 15.6 |

| 7 | 2.25 | 2.94 | 15.6 |

| 6 | *2.20/1.90 | 2.15 | 15.6 |

| 5 | 3.10/3.40/5.30 | 24.5 | 490 |

| 4 | *2.00/1.70 | 2.15 | 15.6 |

| 3 | 2.60/2.90/4.60 | 14.7 | 196 |

| 2 | 2.1 | 2.45 | 15.6 |

| 1 | 1.85 | 9.4 | 15.6 |

*= hoistable deck

Comments

Sorry, comments are closed for this item