As a follow-on from the April issue’s Newbuild of the Month feature about Incat’s latest delivery, the 9,044gt/2019 built Saint John Paul II of Virtu Ferries, this month’s subject was spawned from rival Australian fast ferry builder Austal. The company was founded on 8th August 1988 in Perth, Western Australia, so celebrated 30 years of business in 2018. The headquarters are now in Henderson, Western Australia. Austal set out with a vision to build high quality commercial vessels for the international market and, three decades later, continue to do just that. Today, Austal is a global shipbuilder and defence prime contractor. A recognised world leader in the design and construction of customised commercial and defence vessels, the company lists many of the world’s leading ferry operators, navies and defence forces as valued clients. Austal has delivered and continues to construct more than 300 vessels for 100 operators in 54 countries around the world. An extensive product range includes passenger and vehicle-passenger ferries, patrol boats, high speed support vessels, surface combatants and revolutionary, multi-role vessels.

Austal established a shipyard in the USA in late 1999, and is now one of the largest employers in Mobile, Alabama, serving as the centre of manufacturing for the Littoral Combat Ship (LCS) and Expeditionary Fast Transport (EPF) programmes for the US Navy. In 2011, Austal acquired a major commercial shipbuilding facility at Balamban on the Island of Cebu in the Philippines to construct high speed passenger, vehicle-passenger ferries, offshore crew transfer and windfarm vessels for growing South East Asia markets and beyond. On 14th May 2018 Austal announced investment of up to $30 million for capacity expansion. This investment was focussed on the Company’s commercial shipbuilding facilities in Western Australia and Asia. The Henderson yard received an upgrade to the facilities, including enhanced launch facilities to support large vessel construction and infrastructure upgrades to support improved efficiency across the operations. The Cebu, Philippines, facility received an $18 million investment to more than double the capacity of its existing shipyard with upgrades including a new 120m long and 42m wide assembly hall to enable larger craft to be built here. The work also involved additional assembly bays, material storage and accommodation facilities to allow the workload at the site to increase to more than twice its historic peak. A small commercial shipyard was also opened in Vung Tau, Vietnam, to provide additional high-quality aluminium construction support to Austal’s commercial operations both for modules for larger ships (supporting Austal Philippines) and to build smaller high-speed aluminium vessels. Austal Vietnam operations are operating in a leased facility requiring only minimal capital investment. Austal’s passenger catamarans and monohulls range in length from 24m to 56m (the 56m Halunderjet of FRS was a previous newbuild subject) and can be found at various locations around the world. The Auto-Express range of passenger and vehicle ferries range from 40m to 112m in length with the stabilised monohull varieties (described as trimarans) being 102m long (6,307gt/2010 built Condor Liberation) and 126.70m long (Fred. Olsen Express’ 8,973gt/2005 built Benchijigua Express). At present, only two Austal vessels operate from U.K ports, the Condor Liberation and Irish Ferries’ 8,403gt/2001 built Dublin Swift (built as the Westpac Express). The Austal website shows around 44 vehicle/passenger highspeed craft of which the latest is the subject of this article, the 11,345gt/2019 built Auto Express 109, Express 4.

New Client

Molslinjen, previously called Mols-Linien, is a Danish company that operates ferry services across the Kattegat between the island of Zealand and Jutland, namely Odden-Aarhus/Ebeltoft with crossing times of 75mins and 55mins respectively. Mols-Linien was formed by DFDS in 1964 and sailings began from 18th May 1966. A reduction in traffic following the 1973 oil crisis prompted the company to enter into a joint venture with rival operator Grenaa-Hundested Linien in 1979. In 1984 DFDS sold both operations to J. Lauritzen A/S before a further sale in 1988 to Danish investment company DIFKO. In 1999 Mols-Linien merged with Scandlines’ subsidiary Cat-Link and Scandlines sold its share of the company to the Clipper Group in 2008. The company now trades as MolsLinjen A/S. The Aarhus-Kalundborg route closed on 15th September 2011. The first fast vehicle ferries that Mols-Linien operated were the distinctive 3,971gt/1996 built Mai Mols and Mie Mols, built in Denmark and both scrapped in 2014. The merger with Cat-Link modernised the fast ferry fleet but the region’s first Austal built AutoExpress craft, the 4,859gt/1995 built and 80m long Cat-Link III, was disposed of in 1998. The company’s primary craft became the 5,619gt/1998 built and 91m Incat Mads Mols (ex-Cat-Link V) and the 5,617gt/1998 built and 91m long Max Mols (ex-Caen Express/Cat-Link IV) in tandem with the Mai/Mie Mols. The Mads Mols was sold in 2005 before passing to Fjord Line as Fjord Cat in 2007. A new arrival joined the fleet in the form of the 10,879gt/2009 built and 112m long KatExpress 1 in 2012. She was built as the Norman Arrow and served Dover-Boulogne and then Portsmouth-Le Havre for LD Lines until the sale. She was renamed Express 1 in 2017 and the Max Mols was renamed Max in early 2019. The arrival of the 10,500gt/2013 built and 112m long KatExpress 2 in 2013 pretty much spelt the end of the older craft. She too was renamed in 2017 as Express 2. In 2017 the fleet was boosted by the delivery of the 10,842gt/2017 built and 109m long Express 3, making a quartet of Incat craft. On 1st September 2018 MolsLinjen assumed control of the Bornholmstraffiken services under the name Bornholmslinien. The Express 1 was transferred to the Ystad-Ronne service with the Max (renamed from Max Mols and marketed as the company’s fastest catamaran) as back-up vessel. The new operation also employs two conventional ferries, the 18,009gt/2018 built Hammerhus and the 12,358gt/1978 built Povl Anker. The changes to the Molslinjen fleet and operations prompted the requirement for a newbuild. Reports suggest that the company went to Incat first but they could not deliver a newbuild at the required time as they already had the contract for the new Saint John Paul II of Virtu Ferries (see April issue). So, the Express 4 became the company’s first Austal newbuild when ordered on 24th June 2016 by a A$109 million contract for a 109m long fast ferry. So, a new chapter began with the plate cutting for the vessel getting underway on 26th April 2017. The futuristic looking AutoExpress 109 emerged from the building hall resembling precisely the artist’s impressions of the vessel on 27th August 2018. The passenger accommodation was lifted onto the hulls once the Express 4 was out in the daylight. The complete ferry was launched on 29th October 2018 and then underwent final preparations and sea trials. The AutoExpress 109 is based on Austal’s proven catamaran design integrating a sleek hull form and modern superstructure. The all-aluminium hull is constructed with laser-welded and composite aluminium structural panels. The optimised hull shape and lower deadweight will ensure improved performance and greater fuel efficiency, resulting in lower operating costs and enhanced passenger experience. Austal’s Ocean Leveller ride control system is also fitted. The beam of the 11,345gt vessel is 30.50m, the depth of the large hulls is 7.60m and the hull draught is 3.80m

First in Class – Fourth in Fleet

This first in class newbuild would also become the largest by volume commercial ferry designed and constructed by Austal since 2011 when the 10,371gt and 112m Leonora Christina was delivered.

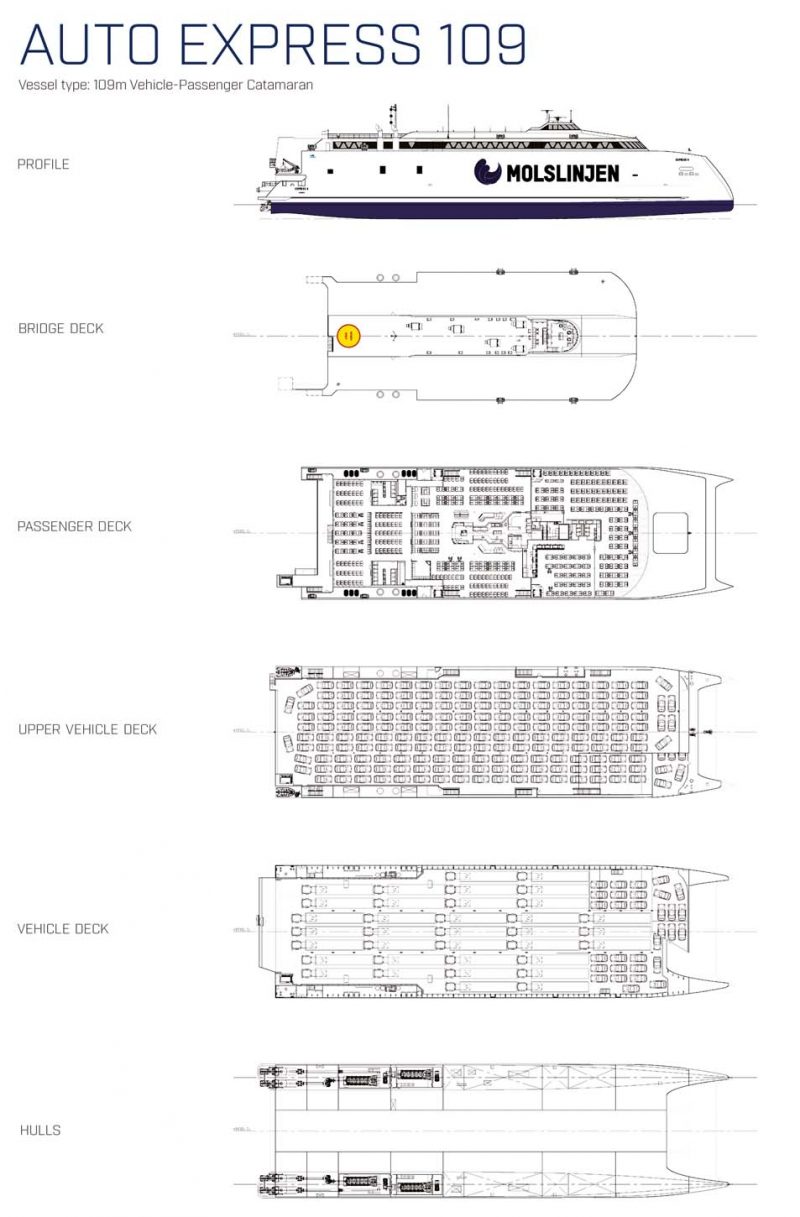

The commercial ferry market has further strengthened over the last 18 months, with various conventional and fast ferry manufacturers seeing their orderbooks expand. Austal is no exception and the Express 4 (Yard No. H363) brings with her a whole new look for the AutoExpress series. The profile maximises capacity and this example is also Austal’s first build that features two full vehicle decks with a total capacity for 425 cars or 610 lanemetres of freight (35 HGVs) and 232 cars. The main vehicle deck is 9 lanes wide with 3 full lanes through the centre, all able to accommodate freight. Areas in the bow also provide space for 31 cars. The deck load for the main deck is 9 tonnes per axle with single tyres at each end and 13 tonnes per axle with double tyres at each end. The truck lanes are 3.13m wide. The upper mezzanine deck (for 186 cars) is 10 lanes wide. A car equivalent unit of 4.5m long and 3.25m wide is the basis for the capacity figures. The deck load for the mezzanine deck is 2 tonnes per axle. One fixed ramp located forward links the two vehicle decks. The vessel is not fitted with any other ramps as what is required is located on the shore based linkspans.

The full width passenger area on the third deck provides up to 1,006 passengers with different seating configurations in the aft, centre and forward lounges along with food and drink outlets plus a small sun deck. The wheelhouse is located above on Deck 4. The machinery spaces are located in the two vast hulls, which also house storage tanks for carrying fuel, lube oil, bilge/sludge, fresh water, grey water and black water. Wärtsilä was contracted to supply four waterjets, hydraulics and a control system for the ferry in May 2017. The Wärtsilä LJX1500 SRI Waterjets offer higher efficiency and cavitation margins, as well as a lower impeller tip speed. The high-performance components were built using stainless-steel to reduce wear and corrosion, while water-lubricated bearings improve the reliability of the waterjets. The bearing block also integrates a sump enabling lubrication to the bearings under all conditions. The waterjets are each driven via ZF 60000 NR2H reduction gearboxes with the power being provided by four MAN 20V 28/33D STC diesel engines that run at 900-1000rpm and provide 10,862-12,069bhp. Each engine is 7.33m long, 2.10m wide, 3.18m high and weighs 46t. Naturally, the machinery is divided between the two hull spaces. With a deadweight of 600t, the ferry operates at a speed of 37 knots at 85% maximum continuous rating (MCR). The maximum service speed will be 40 knots but trial speeds recorded an impressive 47.8 knots (88km/hour). Austal’s ride control system is fitted for passenger comfort.

Express Delivery

The Express 4 was delivered on 30th January, the fourth high-speed catamaran ferry introduced by Molslinjen in just 6 years and reflects the continuing success of the company, which has seen a 46% increase in passenger numbers across its network since 2011. The handover triggered the final A$20 million-plus payment on the vessel, which was built on budget. Approximately 400 Austal employees worked on the vessel during the design, pre-fabrication, construction and fit-out phases of the vessel, drawing upon a supply chain of over 1,000 suppliers Australia-wide and internationally. The Express 4 then embarked upon her 27-day/20,000km delivery voyage to Aarhus, Denmark, from Henderson via Perth, Galle in Sri Lanka (where fresh supplies including clean drinking water and bunkers were taken on), the Suez Canal, Valletta (Grand Harbour), Malta for bunkers and supplies on 18th February prior to arriving home on 24th February. The vessel is expected to commence regular ferry services across the Kattegat from 14th March 2019. Construction of a similar design vessel, a 109-metre vehicle passenger catamaran for Fjord Line of Norway, is already well advanced at Austal Philippines, using the same hull enhancements. Other commercial ferries currently in build at Austal’s shipyards in Australia, Philippines and Vietnam include two 117m vehicle passenger trimarans for Fred. Olsen S.A of Spain, one 83m passenger trimaran for JR Kyushu Jet Ferry of Japan, two 50m catamarans for Brave Line of Taiwan, and one 49m catamaran for SNC Aremiti of French Polynesia. In addition, Austal’s joint venture in China, Aulong Shipbuilding, is currently constructing five 42m catamarans and one 69m catamaran for mainland China operators.

Special thanks must go to Paul Sparke, Austal Marketing Manager, for all their invaluable assistance with information & images.

Technical Specifications

| Order Date | 24th June 2016 |

| Plate Cutting | 26th April 2017 |

| Launched | 16th October 2018 |

| Delivered | 30th January 2019 |

| Shipyard | Austal |

| Place of Build | Henderson Shipyard, Western Australia |

| Yard No. | H393 |

| IMO | 9824564 |

| Flag | Denmark |

| Port of Registry | Aarhus |

| Registered Owner | MolsLinjen A/S – Hveensgade 4, 8000 Aarhus |

| Operator | MolsLinjen A/S – Hveensgade 4, 8000 Aarhus |

| Route | Odden-Aarhus |

| Class Society | DNV |

| Classification | 1A HSLC R1 Ferry B E |

| Gross Tonnage | 11,345 |

| Net Tonnage | 3,404 |

| Deadweight | 1,070 |

| Length Overall | 109.00m |

| Length b.p | 105.00m |

| Beam | 30.50m |

| Hull Depth | 7.60m |

| Hull Draught | 3.80m |

| Machinery | 4 x MAN 20V 28/33D STC |

| Power Output | 36mW |

| Auxiliary Engines | Information not supplied |

| Gearboxes | 4 x ZF 60000 NR2H |

| Propulsion | 4 x Wartsila LJX1500 SRI Waterjets |

| Ride Control | Austal Ocean Leveller |

| Service Speed | 37 knots with 600 tonnes deadweight |

| Maximum Service Speed | 40 knots |

| Trials Maximum Speed | 47.8 knots (88km/hour) |

| Range | 600 nautical miles |

| Capacity (Lanemetres) | 610lm for freight (35 HGVs – plus 232 cars) |

| Passenger Capacity | 1,006 persons |

| Car Capacity | 425 cars (with no freight aboard) |

| Crew | 22 |

| Main Deck Clearheight | 4.60m |

| Mezzanine Deck Clearheight | 2.10m |

Comments

Sorry, comments are closed for this item