Hagland Shipping, part of Hagland Bulk Transport KS, of Norway took delivery of the first in a series of three new battery-hybrid self-unloading bulkers from Dutch shipbuilding company Royal Bodewes in The Netherlands on 21st October. The first order for two such newbuilds was placed on 8th April 2021 with a third sistership being ordered at the end of February 2022. These newbuilds have zero emissions whilst in port and achieve a substantial reduction of emissions whilst underway at sea. Hagland Shipping aims to achieve greener short-sea shipping through reduced local and global greenhouse gases and reduced noise. The third ship is scheduled to be delivered mid-2023 whilst the first two sisterships were scheduled for delivery autumn 2022 and early 2023.

Together, the trio of newbuilds will replace older ships in Hagland’s fleet that are equipped with traditional propulsion systems. The ships are also prepared for zero-emission technology and satisfy IMO TIER III requirements. The total investment for each ship was in the regions of NOK 150 million ($16.8 million), totalling NOK 430 million for the series of newbuilds. The newbuilding contracts were entered into on the basis of substantial support from financial technology company ENOVA (the Norwegian Ministry of Climate and Environment’s organisation aiming to reduce emissions and develop energy and climate technology), which has been instrumental in the realisation of the project. The investment was also supported by the fleet renewal programme for short sea shipping. Hagland Shipping was established in 1983, and has since developed into a fully integrated ship-owning/operating company with a fleet of self-discharging dry-cargo vessels.

At the time of writing, the fleet consisted of 13 vessels, of which six were owned by Hagland and seven were on time charters, plus the two newbuilds expected in 2023. The fleet members were listed as:-

Famita (2,999gt/built 2002/6,063m3 capacity), Falkfjord (2,834gt/ built 1998/5,718m3 capacity), Falksea (2,999gt/built 2002/6,063m3 capacity), Falkbris (2,449gt/built 1992/4,650m3 capacity), Vestborg (2,446gt/built 1993/4,650m3 capacity), Imperator (2,446gt/built 1992/4,650m3 capacity), Hagland Borg (2,456gt/ built 1997/4,650m3 capacity), Hagland Boss (2,446gt/built 1997/4,650m3 capacity), Hagland Saga (2,999gt/built 2003/5,850m3 capacity), Hagland Chief (2,984gt/built 2012/5,720m3 capacity), Hagland Carrier (2,984gt/built 2011/5,720m3 capacity), Hagland Captain (2,984gt/built 2012/5,720m3 capacity) and the subject of this feature, the new generation Hagland Pioneer.

The fleet of ships are all dry-cargo self-dischargers, but the company has experience from other segments in the industry. Typical cargoes include timber, pulpwood, woodchips, sand, gravel and other stone products, as well as a number of other bulk cargoes. The majority of cargoes involve rock materials, sand and limestone with timber/woodchips being the second most prevalent cargo. The main operating area is in the North Sea and Baltic in the short-sea trade. The ships operate around 1,100 voyages per year, encompassing 250 different ports and around 2,500 port calls.

The company can trace its roots back to 1872 when Rasmus Gautsen Hagland established himself as a shipowner and shipbroker. In 1884 a hurricane in Iceland destroyed Hagland’s largest ship, the brig Norden, which lead to financial difficulties. In 1927 the company was taken over by the Aanensen family when Rasmus G. Hagland passed away. In 1950 the next generation of the family expanded the business, focussing on sale and purchase deals and newbuilding orders. Further expansion followed and, in 1983, Hagland also acted as broker for its first chemical tanker. In 2007 a fleet renewal and expansion programme commenced for Hagland Shipping with further growth in 2011. In 2012 newbuilds were delivered and in 2018 RG Hagland Shipbrokers and North Sea Shipbrokers joined forces in the renewables market. In 2019 came the rebranding of the shipbroking services in Haugesund, Esbjerg, Hamburg and Aberdeen with the new generation of ‘green’ newbuilds being ordered in 2021. The present-day Hagland embraces international shipbroking, shipowning, marine agencies, business management and accounting services and real estate. The company, with headquarters in Haugesund, Norway, is owned by brothers Arne and Knut Wendelbo Aanensen, representing a third generation of Aanensen family ownership.

Pioneering Era

The first two members of the new generation of ‘eco’ newbuilds were ordered 8th April 2021 from Dutch shipyard Royal Bodewes. These Bodewes-designed Eco-Trader 5150 self-discharging bulk carriers have a deadweight of 5,000 with an emphasis on zero emissions whilst in port and a substantial reduction of emissions during sailing. The company also aims to achieve greener short sea shipping through reduced local and global greenhouse gases and reduced noise so the vessels are optimised with a plug-in battery hybrid solution that satisfies IMO TIER III requirements. Compared to Hagland’s existing fleet, the vessels were expected to reduce CO2 emission by more than 30% and NOx emissions by 90-95% from delivery. There was an option for a further two sisterships with one option being taken in early 2022 as mentioned above. At the time of the newbuild announcement, Hagland Shipping was retrofitting the 2,984gt/2012-built Hagland Captain, which became the world’s first battery hybrid vessel in the dry cargo short-sea market, a project that was carried out in co-operation with Norwegian company NOAH. The Royal Bodewes Shipyard dates back to 1812 when Shipbuilder Geert Joosten Bodewes registered the company. The shipyard produced various types of wooden barges and coastal vessels. Geert’s second son, Wijnandus, became the second generation’s business leader and the business flourished. In 1882, he turned the management of the shipyard over to his sons Geert and Harmannus.

In addition to the traditional timber construction, the company introduced ironclad and later steel-clad vessels. Some of these are still in operation. In 1908 the focus turned to steamships and, in 1911, the two brothers (whose company was now called G. & H. Bodewes) transferred the leadership of the company to their oldest sons Herman and Nandus. The introduction of the diesel engine led to the construction of motorised barges and coastal vessels. NB 606 was launched on the 18th May 1916. In January 1918 the vessel was sold to her first owner Holmen Bruks & Fabriks, Norrköping where she was used for towing wood to the paper factories in Norrköping or in Hallstavik. In 1969 the vessel was sold to the captain and was renamed Holmvik. In 1976 the vessel was sold to the AVRO (a Dutch television organisation) and was renamed Furie. After being used for a television series, she was sold to the foundation Hollands Glorie and the vessel even has her own website. In 1924, the company was expanded by the purchase of a shipyard in the town of Hasselt. After the Dortmund-Ems Canal was opened, the Hasselt and Martenshoek shipyards produced dozens of ‘Dortmunders’. The first wholly engine powered coastal vessels were built in 1931. In the 1970s, an imposing construction hall was built at the shipyard and, for a number of decades, the shipbuilding business also operated its own shipping company with an average fleet of five vessels. In 1986, when the shipyard management no longer had family members to serve as successors, it was transferred to non-family members.

In 1988, the company signed a contract to build two multi-purpose ro-ro vessels. These were the very first of their kind, so the shipyard found itself designing technically advanced parts like loading flaps and loading lifts without any frame of reference. The 4,250dwt ship was introduced to the world in 1990 and six were built. The new millennium brought a succession of new ship types designed by Bodewes that responded perfectly to the needs of the market. In 2010, Bodewes Shipyards and Universal Africa Lines (UAL) arrived at a partnership for the building and operating of the Eco Trader 8700 series of ships. In 2012, the shipyard celebrated its 200th jubilee and received the honourable title of ‘Royal’ on this occasion. On 30th November that year her majesty’s provincial governor Mr Max van den Berg officially granted the honourable predicate of ‘Royal’ at the Hoogezand shipyard on behalf of the Queen of the Netherlands. Since then, the Bodewes Shipyards have been known as Royal Bodewes.

Another building hall was then added to the site and the waterway next to the shipyard, the Winschoterdiep Canal from Groningen, was widened for the purpose of launching newbuilds sideways. The shipyard now has an impressive portfolio of designs for cargo vessels in a range of 1,500dwt up to 15,000dwt not to mention specific vessel types such as oil tankers, paper carriers, LNG carriers, cement carriers and tugs.

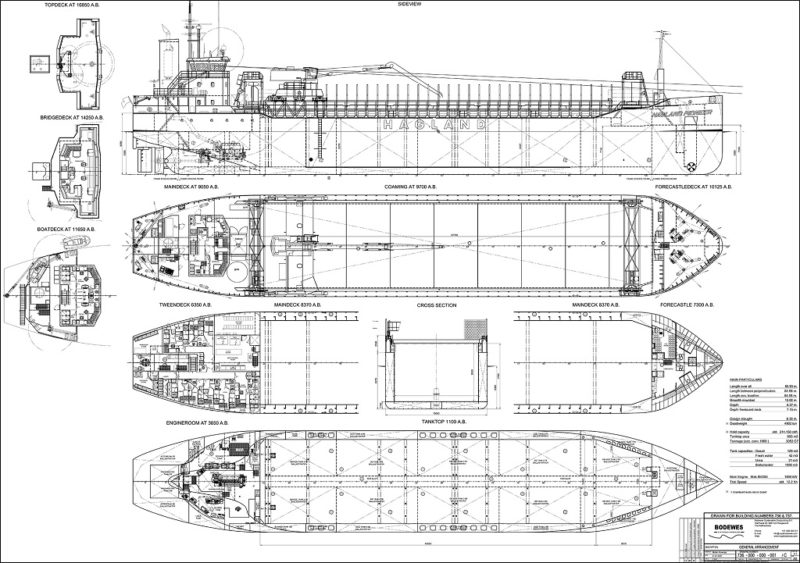

Yard No. 736 became an example of 21st century shipbuilding at the shipyard with a hybrid solution to make her as environmentally friendly as possible. The vessel was named Hagland Pioneer just prior to being launched at the Foxhol Shipyard, just along the canal from Hoogezand, on 27th May 2022. The sideways launching technique always delivers a spectacular sight, and this occasion was no exception. Once fitting out and sea trials were completed, the ship was handed over to Hagland Shipping on 21st October 2022. The deckhouse is situated at the stern with the box hold measuring 57.75m long and 12.40m wide with an internal clear height of 8.68m. The single hold is covered by 10 pontoon-type hatches that are removed/replaced by a gantry crane which travels on rails the length of the hold and is stowed in front of the superstructure. The load capacity of the tank top is 15 tonnes/m2 when the hatches are in place. The hold is designed for dry bulk cargoes and also has a pair of two-part grain bulkheads. The self-discharging capability of the ship is via a Fuchs MHL890 F. This 360-degree cargo handler is carriage-mounted on the rails that run along the edge of the cargo hold. Equipped with a 250kW electric motor, the machine has a maximum outreach of 24.50m and can handle various materials including coal, grain, logs, scrap and big bags using a grab, clamshell or lifting hook. The Operator’s cab is telescopic to maximise visibility during loading/unloading. The machinery spaces are located aft on the appropriately named Engine Room deck and house a MaK Caterpillar 6M25E 1,800kW/2,446hp and 6-cylinder marine diesel unit plus two 147kVA 118kW/175hp generators and a single 81kVA 65kW/101hp emergency generator. This engine is 8.70m long and 4.30m high when fully assembled with all components, and the width is 1.70m. The dry weight of the engine is 21 tonnes and the dry weight of the generator set is 44 tonnes. The cylinder bore is 255mm and the stroke is 400mm. Propulsion is via a 10m diameter/140rpm controllable pitch screw propeller driven via a Siemens gearbox. Manoeuvrability is assisted by a 450kW transverse tunnel bow thruster. Above the machinery spaces is the Tweendeck and, on the port side, is the battery room that houses a 1000kwh EST-Floattech DNV-certified Green Orca battery system. The ship can sail in fully electric mode in ports, fjords or near coastal communities plus the batteries are also used for peak shaving. EST-Floattech was contracted by system integrator Hoogendijk Electric to design and deliver the complete battery system for the Hagland Pioneer and her sisters. When there is no shore connection available the battery system also allows for zero-emission discharging of the transported bulk cargo. The batteries can be charged during transit or in harbour via the shore connection. The EST-Floattech system includes battery management software and control units for enhanced safety. The Tweendeck also offers 6 crew cabins and facilities plus en-suite accommodation for the Chief Officer and another Officer. At Maindeck level in the deckhouse is mess room, office, galley and pantry plus utility areas. One level up on the Boatdeck is the en-suite accommodation and day rooms for the Chief Engineer and Captain. The upper-most level (besides Topdeck) is the wheelhouse on the Bridgedeck. The new ship has a striking blue and green livery and, at the time of writing, was hard at work and en-passage between Kambo and Trondheim in Norway. Her sisterships will be joining her during 2023.

Comments

Sorry, comments are closed for this item