On 29th August Intermarine, LLC announced the delivery of the Industrial Skipper, an S-Type 500 Class Heavy- Lift Box-Hold MPP Tweendecker, from a shipyard in Rongcheng, China. Intermarine is a global leader in the transport of project, breakbulk and heavylift cargo. Founded in 1990, the company, through its subsidiaries and worldwide network of 20 offices, operates a flexible international fleet with lifting capacities up to 1,400 metric tons. The company also provides ocean transportation and marine logistics services with regular sailings in the Americas, West Africa, Europe, Asia and the Middle East, plus inducement voyages to Australia and other international ports. The company operates the largest U.S. flagged heavy-lift fleet and controls Industrial Terminals (Houston), the busiest project cargo terminal in the USA. As of October 2016 the company listed a fleet of 40 ships plus one SType 500 to still be delivered in 2016 (the Industrial Strength) and one S-Type 900 to be delivered in 2017. The oldest fleet members date from 1999. In 26 years the company has delivered 70 million cubic metres/31 metric tonnes of cargo and its ships have travelled 36 million nautical miles at sea. The ship began life as Yard No. HCY-166 at Huanghai Shipbuilding Co., Ltd. that manufactures Ro-Ro passenger ships, bulk carriers, and container vessels. The company was formerly known as Shandong Huanghai Shipbuilding Co. Ltd and changed its name to Huanghai Shipbuilding Co., Ltd. in 2007. The company was founded in 1944 and is based in Rongcheng, China. Rongcheng is a county-level city of Weihai City, at the eastern extremity of Shandong Province, China, looking out to the Yellow Sea in all directions but the west. Intermarine, LLC announced back on 12th May 2014 that it was adding a total of 15 vessels to its fleet to meet the rising demand from its valued customers regarding the shipment of heavy lift and project cargo. The fleet renewal programme involved long term charters on a series of new vessels from Sanfu Shipyard & Huanghai Shipbuilding Co. Ltd, two of the foremost builders of ships in China. These state-of-the-art, fuel-efficient, eco-friendly newbuilds, to be delivered 2016-2019, would form the backbone of the fleet and further enhance Intermarine’s commitment to maintaining its status as a high quality partner and operator in heavy lift/project transport.

An Eco-Lift 500 is Born

The keel for HCY-166 was laid on 15th October 2015 and the hulk of the ship was launched 15th January 2016 when fitting out commenced. The S-Type Eco-Lift 500 class of ship has an overall length of 147m, a beam of 22.80m and a draught of 8.10m. The ship’s deadweight is 12,500dwt.

Designed to be more ecologically friendly, the Eco-Lift 500 fleet members boast reduced consumption and lowered greenhouse emissions whilst complying with the latest waste water requirements and ECA zone fuel requirements. The specifications of the Eco-Lift 500’s class include, heavylift gear, long hatch, flexibility, green passport, and state-of-the-art hold and hull technologies that meet all modern standards. Yard No. HCY-166 had the name Industrial Skipper bestowed upon her. Perhaps not the most inspiring name, or series of names for the entire class, but like so many newbuilds, the name reflects the practical role of a working ship such as the Eco-Lift 500 within the marine trade.

Industrial by name and nature

The Industrial Skipper is the first S-Type Ecolift 500 vessel to be delivered in Intermarine’s Fleet of the Future fleet renewal programme. Vessels will continue to deliver until 2019. The size and configuration of these newbuildings’ holds improve capacity and flexibility for the worldwide trading of project cargo. The increased crane capacity and performance across the fleet will also speed up port time for cargoes. There are two additional models in the Fleet of the Future project, namely the Eco-lift 300 (8,500dwt, 300t lifting capacity, delivering 2018) and the Eco-lift 900 (13,300dwt, 900t lifting capacity, delivering 2017-18). Operating a core fleet of sister vessels of the same configurations will enable Intermarine to more quickly assess the requirements of its customers and to reap the benefits of crews that are experienced and knowledgeable with client cargoes and vessel capacities. After sea trials were completed the 11,436gt Industrial Skipper was delivered in July 2016.

Industrial Capacity

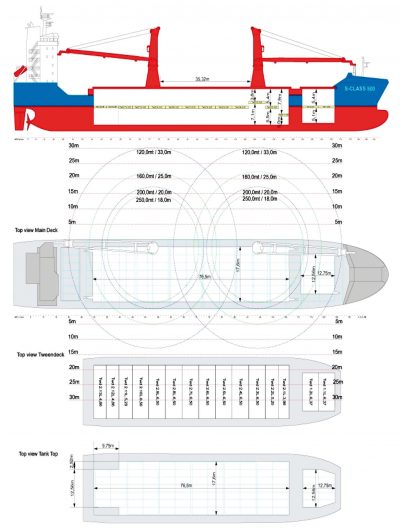

The ship’s cargo hold is split into two sections. The large box shaped hold (Hold 2) measures 76.5m in length and 17.6m in overall width. At the aft most end of the hold the width steps down by 2.52m each side to 12.56m for a distance of 9.75m. The depth of the hold is 12.50m and the hatch height is 11.60m. The smaller forward hold (Hold 1), located in the bow, is slightly tapered but measures 12.75m long, 12.56m wide with a depth of 9.30m and hatch height of 11m. The overall cubic capacity of the holds is 16,180m3 with tweendecks and 17,600m3 without them. The ventilation hatch dimensions match the length and width of both holds and the hatch covers are of the hydraulic folding and pontoon types. Hold 1 has two movable tweendeck sections with 1 position and Hold 2 has 13 movable tweendeck sections with 3 positions. The tweendeck in Hold 1 fixes to provide a lower level clearance of 4.90m (tanktop to below tweendeck). The tween-deck sections in Hold 2 can be positioned to provide a lower/upper level clearance of 3.00m/7.90m, 5.50m/5.40m and 7.10m/3.80m (tanktop to below tweendeck/tweendeck to hatch). The heights can vary between all three levels to accommodate varying cargoes in one shipment. The tweendecks (pontoons) can also act as bulkheads to sub-divide the cargo holds. The tweendeck sections are each 6.37m long in Hold 1 and are of various lengths in Hold 2. (3.98mx1, 4.86mx2, 5.20mx2 and 6.50mx8). The deck load capacities per square metre are as follows: Tanktop 16t/m2, Tween Deck Hatch, 4t/m2, Weather Deck Hatch, 4t/m2 on the hatch covers and tonnest/m2 on the strengthened pontoons over an area of 35.32m between the cranes. A fire resistant A60 bulkhead separates Holds 1 & 2 plus Hold 2 from the crew and machinery spaces located aft. As well as project and mixed dry cargoes the Industrial Skipper can accommodate 838 TEU containers. A total of 316 TEU can be stowed in the holds and a further 522 on the weather deck. Guides are positioned down the front of the superstructure to protect it from the cargoes being carried.

A total of 50 Reefer plugs are also provided to supply power to temperature critical goods within Reefer containers. This and other payloads can be loaded/unloaded by port cranes or by the ship herself, providing greater operational flexibility. So, the ship can service small or rural ports/quaysides, barges moored alongside or offshore facilities. The bridge is cut away on the port side to create operating space for the two electro-hydraulic cranes. The cranes are manufactured by TTS NMF GmbH of Hamburg, Germany, part of Norwegian TTS Group ASA. Interestingly, on 19th June 2016 the Boards of Directors of TTS Group ASA and Palfinger Marine GmbH entered into a transaction agreement regarding an acquisition of TTS Group ASA by Palfinger Marine GmbH. The maximum outreach of each crane is 33 metres at a safe working load (SWL) of 120 tonnes. At 25 metres the SWL is 160 tonnes, at 20m the SWL is 200 tonnes and the maximum load of 250 tonnes (500 tonnes combined lift) is achievable at a maximum outreach of 18 metres. The operational hook (lift) height for loading/ unloading cargo over the ship’s sides is 35 metres. The large dimensions of Hold 2 and the weather deck make both ideal for shipping 65m long and 10 tonne wind turbine blades among other abnormally sized consignment types such as 200t cable reels, 213 tonne pipe rack modules or 50m long/300 tonne reactors (loaded using the cranes operating in tandem).

Full-Ahead Skipper

The S-Type 500 Eco-Lift ships are powered by a single Wartsila two-stroke 6950kW engine that operates at 111 rpm. More precise details of the ship’s machinery had not been provided by the time the article went to press. Propulsion is provided by a single fixed pitch propeller and the maximum speed is 15.10 knots. The service speed for economy is 12.50 knots. A single 600kW transverse tunnel thruster is located in the bow for manoeuvrability and the ship can carry 734m3 of Heavy Fuel Oil (HFO) and 185m3 of Marine Grade Oil (MGO). An exhaust scrubbing system is installed so the cheaper HFO can still be used for sea voyages. The superstructure located aft consists of six decks that house the Hospital, Crew/Officer mess rooms, Crew/Officer day rooms, changing room, sauna, recreation room, fitness room and cabin accommodation for a minimum of 9 crewmembers. A diagram was not provided so the precise deck arrangement cannot be described on this occasion. Following her July delivery, the Industrial Skipper transported 185 tonne and 217 tonne pipe rack modules to Corpus Christi, Texas, for her maiden voyage. After discharging her cargo, the Industrial Skipper then participated in a welcome event during mid-September at Intermarine’s Industrial Terminals facility in Houston.

Special thanks must go to Leah Martinez, Director of Marketing, PR and Communications at Intermarine, LLC for the provision of information and images/diagrams.

Technical Specifications

|

Ship Class |

S-Type 500 |

|

Ship Type |

Heavy-Lift Box-Hold MPP Tweendecker |

|

Shipyard |

Huanghai Shipbuilding Co. Ltd. |

|

Location |

Rongcheng, China |

|

Yard No |

HCY-166 |

|

IMO |

9741138 |

|

Operator |

Intermarine, 55 Waugh Drive, Suite 300, Houston, Texas, 77007, USA |

|

Registered owner |

Jaune International SA c/o Argo Coral Maritime Ltd, Middenweg 35A, 4782 PM Moerdijk, The Netherlands |

|

Ship Manager |

Argo Coral Maritime Ltd, Middenweg 35A, 4782 PM Moerdijk, The Netherlands |

|

Keel laid |

15th October 2015 |

|

Launched |

15th January 2016 |

|

Delivered |

July 2016 |

|

Port of Registry |

Monrovia |

|

Flag |

Liberia |

|

Class |

Lloyds Register |

|

Gross Tonnage |

11,436 |

|

Deadweight |

12,300 |

|

Net Tonnage |

4,500 |

|

Draught |

8.10m |

|

Length Overall |

147.00m |

|

Beam |

22.80m |

|

Max. Speed |

15.10 knots (approx.) |

|

Eco-Speed |

12.50 knots (approx.) |

|

Machinery |

1x Wartsila two-stroke 6950 kW x 111 rpm |

| Auxilliary Engines | Details Not Supplied |

|

Propeller |

Fixed pitch propeller (Details Not Supplied) |

|

Bow Thruster |

1x 600kw transverse tunnel thruster |

|

Cranes |

2x 250t electro hydraulic cranes. Can combine to lift 500t maximum, incl. use of a spreader bar. Portside mounted |

|

Manufacturer |

TTS NMF GmbH, Hamburg, Germany |

| CAPACITIES | |

|

Cargo Holds |

16,180m3 with Tweendecks/Bale 17,600m3 without Tweendecks |

|

Containers |

838 TEU – Hold 316/Deck 522 + 50 Reefer Plugs |

|

Deckloads |

16t/m2 on tanktop, 4t/m2 on tweendeck, 4t/m2 on hatchcovers & 8t/m2 on pontoons between crane posts. |

|

Tank Capacities |

Heavy Fuel Oil (HFO) 734m3/Marine Grade Oil (MGO) 185m3 & Fresh Water 154m3 |

|

Crew |

9 (Minimum) |

|

Special Features |

CO2 fitted, IMO fitted, Lakes fitted, Australia fitted |

|

S-Type 500 Fleet |

Industrial Saint, Industrial Skipper, Industrial Song, Industrial Spirit, Industrial Star, Industrial Strength, Industrial Song, Industrial Success, Industrial Sun & Industrial Swift |

Comments

Sorry, comments are closed for this item