Maersk Supply Service (MSS) became the first Scandinavian shipping company to enter the offshore market in 1969 and was later established as an independent business unit in the A. P. Moller-Maersk Group in 1974. Five years later MSS had developed into the leading owner and operator in the field of large offshore support vessels with the delivery of the first anchor handling tug supply vessel of more than 10,000bhp. In 1994 MSS diversified into the cable laying market following the conversion of the platform supply vessel Maersk Fighter into a cable vessel. The following year the company exited the anchor handling tug supply vessel market in terms of tonnage with an output of less than 10,000bhp. Two years later the first 20,000bhp anchor handling tug supply vessel (AHTS) was delivered to the fleet. The first four custom built cable vessels were ordered in 1998 and in 2000 the first A-type AHTS of over 23,500bhp arrived in the fleet. Maersk Supply Service A/S was established in 2008 as a separate limited company with its own dedicated HSEQ function with a fleet renewal programme being completed two years later with the delivery of 18 new vessels, representing an investment of more than $1 billion. A further two AHTS were ordered in 2011 with a further 11 new-buildings (six AHTS and five subsea support vessels) ordered in 2014.

In response to a global downturn in the offshore market sector, Maersk Supply Service entered into agreements with two shipyards during the summer of 2017 to postpone the delivery of a total of nine newbuildings. The vessels in question included five Starfish Class AHTS which are under construction at the Kleven Yard in Norway, and the four Stingray Class subsea support vessels, being built by China’s Cosco Dalian shipyard. This deferral was seen by all parties as the best possible solution given the market situation at the time. The first Starfish Class AHTS, the 10,181gt Maersk Master, was delivered in March this year, while vessel number two, the Maersk Mariner, was delivered in late June 2017. The next three Starfish ships from Kleven will be delivered in 2018, and the last in the series will arrive in 2019. The present day fleet consists of over forty vessels as follows:-

Anchor Handler Tug Supply Vessels for supply & cargo duties, pipe transportation, stand-by and firefighting.

Anchor Handler Tug Supply Vessels for FPSO installation, hook ups, rig moves, towing, supply & cargo duties, subsea installation support, trenching & ploughing.

Subsea Support Vessels for support infrastructure, FPSO installation, trenching, cable-laying, dive support, surveying inspection, maintenance & repair, well stimulation and intervention.

Until the 2017 deliveries commenced the newest vessel in the MSS fleet was the 10,181gt cable layer Maersk Connector, delivered in 2016 and the subject of a previous newbuild feature.

First in Class

The aforementioned delivery delays also postponed the debut of the first member of the Stingray Class quartet, the subject of this feature. The four vessels represented a $470 million contract with the Dalian COSCO yard, a subsidiary of the COSCO Shipyard Group secured in August 2014.

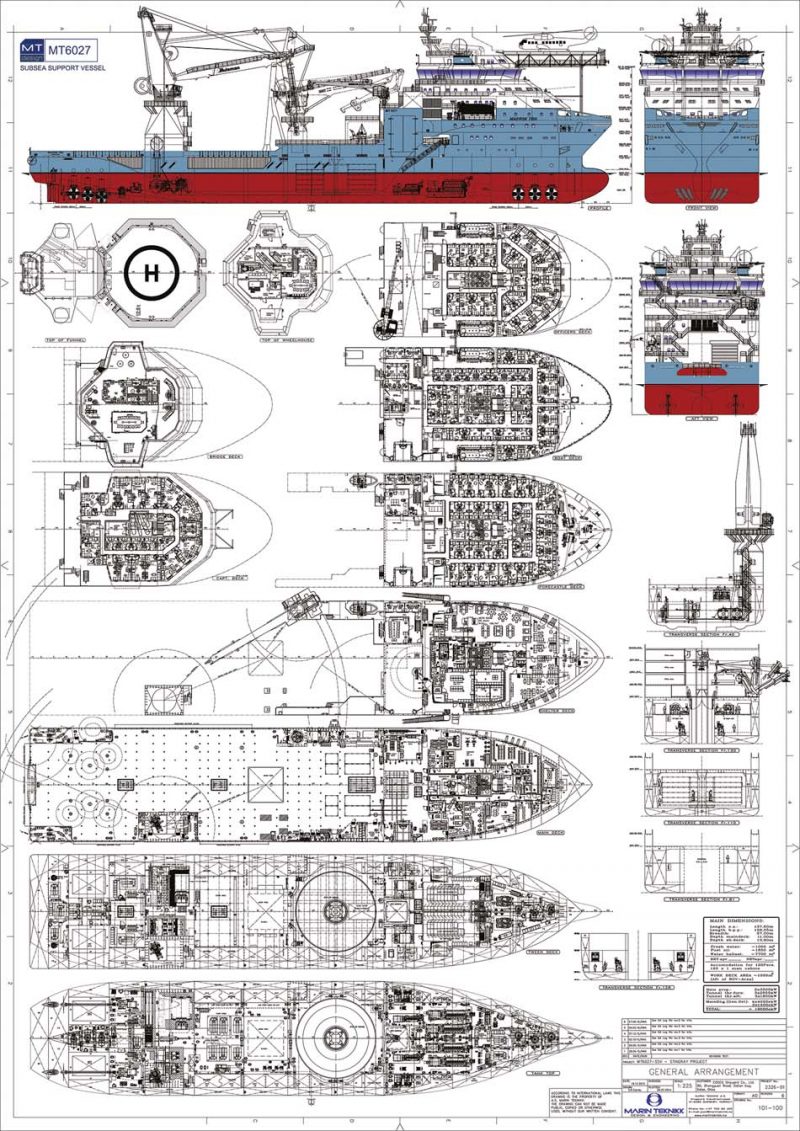

The keel laying ceremony for all four Subsea Support Vessels (SSV) took place on 9th December 2015. The new class of SSV was assigned the name Stingray as the stingray fish is an elegant and powerful fish able to ‘operate’ both at the sea’s surface and along the seabed, rather like a state-of-the-art SSV. The sleek profile of the ship even bears resemblance to its namesake cartilaginous fish. The vessels are of the MT6027 Marin Teknikk design with a length overall of 137.60m, a beam of 27m, a scantling draught of 8.00m and a hull depth from the main deck of 11.00m.

The Stingray class is a series of highly versatile vessels designed as a flexible, stable and reliable platform to carry out a wide range of deep and shallow water operations in challenging offshore environments. With a very energy efficient propulsion set-up, these DP3 equipped vessels feature a 400t active heave compensated crane and 2 work class ROVs capable of operating in a water depth of up to 3,000m. The first class member began life as Hull No. N450 when her keel was laid on 9th December 2015 at the Cosco Dalian Shipyard located in Dalian Bay, Dalian, China. This shipbuilding facility was established in 1992 and is currently one of the largest yards within the COSCO Shipyard Group, which is 51% owned by Singapore-listed COSCO Shipping International (Singapore). The site has a total land area of 1,400,000m2 and more than 2,500m of deep water quays and berth facilities. The shipyard has an annual capacity to repair or convert 150 vessels of various types and its annual building capacity is 1,500,000dwt. The Stingray newbuild was launched on 27th October 2016 with delivery following on 16th October 2017. The MSS ships generally carry a name relating to their function and purpose so it was rather appropriate that Hull No. 450 should receive the name Maersk Installer. The ship is 10 decks high with the superstructure located forward and the following serves as a “walk through” guide to the layout of the accommodation, with the equipment and machinery detail to follow. The lower decks (Tank Top & Tween Deck) are occupied by machinery and equipment whilst the third deck up is the Main Deck. In the bow section can be found a host of facilities including a 60m2 gymnasium, 67.6m2 locker room, 22m2 general store, 16m2 linen room, 36.9m2 laundry, 28m2 engine control room, a 15.5m2 coffee shop, a 14.6m2 coffee shop for smokers, an 11.7m2 hospital plus ROV services. The next level within the superstructure is the Shelter Deck. This area boasts a multitude of amenities including 3 lounges (56.3m2, 27.6m2 and 61.4m2 respectively) overlooking the bow, food stores, galley, bakery, scullery, a conference room, 2 offices plus a 157.6m2/66 seater mess room on the port side. The Forecastle Deck contains much of the modern, spacious and comfortable cabin accommodation aboard plus, at the aft end, a WROV hangar, control room plus a further 2 offices on the port side. The Boat Deck offers the remainder of the personnel cabins (38) plus 5 offices port side aft and stowage for the 2 lifeboats, one on either side. The Officers Deck consists of 14 crew cabins, 4 unallocated cabins plus those for the crane drivers and electricians (4 in total). Up another level is the Captain’s Deck containing the Captain’s accommodation plus likewise for his Officers, Navigators, Engineers and Chief Steward (11 cabins) plus a further 7 cabins including 3 for V.I.Ps. The Ship Management Office and Emergency Control Station are also on this deck. The large, 360 degree visibility Bridge Deck incorporates conference and office areas. From here all operations can be overseen including use of the cranes, the dynamic positioning when the ship is holding her position at a work site and of course for general navigation. Above the Bridge Deck is a further conference area plus a V.I.P office.

Built for Purpose with Versatility

At Tank Top level aboard the Maersk Installer can be found the machinery spaces located forward. There are three fixed pitch Schottel STT 7 FP transverse tunnel thrusters at 2,750kW each and aft of this equipment is the main engine room. Here can be found four 4,220kW and 8-cylinder MaK 8M32E and two 8-cylinder, 1,400kW MaK 8M20C engines that form the basis of the vessel’s diesel electric propulsion system. Caterpillar Motoren designed the M32E marine power unit based on the reliable M32C engine series. The M32E shares the same footprint as the successful M32C and is the first MaK 5 MW engine in the 320mm bore segment. The power range for these engines is 720-750rpm with a stroke of 480mm.

The M20C engines offer an output of 1020-1800kW, a 900-1,000rpm speed range, a 199mm bore and a 299mm stroke. Electrical power on board is supplied by four Siemens 6600V/4689kVA and two Siemens 6600kV/1556kVA generators. Aft of the machinery spaces is a 4.80m x 4.80m ROV Moonpool in the ROV garage that provides subsea access from the Main Deck. Astern of this is located an area for a 3,000t cable laying carousel followed by an 8.40m x 8.40m Moonpool that provides subsea access from the open Main Deck. These Moonpools are accessed from the Main Deck and run down through the ship from there. The Moonpools are covered by flush hatch covers when not in use and both are equipped with a splash damping system. The aft superstructure on the Main Deck also houses the ROV workshop, switchboard room and store. In the aft section of the Tank Top can be found various machinery spaces including the pump room, lower winch room plus the port and starboard propulsion rooms. Powered via the diesel electric system, each 3,500kW propulsion motor drives a 4.00m diameter controllable pitch Schottel SWL420 propeller. The service speed is 14.0 knots at a draught of 5.50m. Also located towards the stern are three Schottel STT 6 FP transverse tunnel thrusters at 2,000kW each. Together with the bow thrusters, these not only enhance manoeuvrability but are also employed when the vessel is operating with her Dynamic Positioning (DP3) system. The Tween Deck above features the upper areas of several of the machinery spaces and facilities below, plus a store area, upper winch room, transformer rooms and steering gear compartments. Cofferdams are built in above all tanks to ensure efficiency and flexibility for client operations. Around two thirds of the Main Deck consists of the large 83m long, 26m wide and 1,850m2 free deck, which is uniquely designed with hundreds of non-welded sea fastening features. The deck load is 5,300t per square metre above the deck and the deck strength aft of the frame is 126:10t/m2. In addition to the area below decks set aside for a cable laying carousel, the work deck is also prepared to receive a 275t cable laying tower to offer this range of subsea work. Located towards the stern of the work deck on the starboard side is a full active heave compensated Huismann crane able to operate to a subsea depth of 3,000m with a maximum capacity of 400t when lifting above the water.

The safe working loads are 377t at 1,000m, 297t at 2,000m and 217t at the maximum 3,000m depth. Just behind the superstructure on the port side of the work deck is a smaller full active heave compensated SMST crane also able to operate to a subsea depth of 3,000m with a maximum capacity of 100t when operating above the water. The safe working loads are 93t at 1,000m, 73t at 2,000m and 53t at the maximum 3,000m depth. Both cranes can perform lifting duties through the large Moonpool. The Forecastle Deck features, at the aft end, a two-storey high WROV hangar on the starboard side, including a hydraulic gantry to swing either of the two ROVs out from the ship’s side for launching. When not in use the hangar is protected by shell doors in the ship’s side. At the rear of the Officer’s Deck accommodation is the stores crane (10t SWL at 18m) on the starboard side plus a 290m3 roll reduction tank. Atop the Bridge Deck are the exhaust outlets on the port side, which are bare pipes so not aesthetically pleasing. Also at this level is the firefighting, reception and control room facilities for the forward mounted Helideck. This platform has a diameter of 22m, a take-off weight of 12.6t and is CAP 437 certified. The Helideck can accommodate Sikorsky S92/S61 helicopters. The Maersk Installer can not only perform numerous offshore/subsea maintenance and construction tasks but she can also undertake towage duties if required. The bollard pull is approximately 100t and a 3.00m long/50t capacity stern roller is fitted plus two 15t capacity tugger winches. As can be seen, the key philosophy behind the design and features of the Stingray Class ships is to be able to adapt to the diverse requirements of clients. The versatility and flexibility of the equipment spaces onboard allows this to be achieved with ease. The ships have also been designed with energy efficiency as a priority thus fuel consumption is kept to a very low level.

The Maersk Installer was both christened and delivered to MSS on 16th October 2017 at the Cosco Dalian Shipyard. The naming ceremony was undertaken by her Godmother (Sponsor) Annette Mikkelsen. The second $117.5 million Stingray Class member, the Maersk Involver (Hull No. N451), was delivered on 28th November and the first 2018 delivery will be Hull No. N452, the Maersk Inventor. In July 2017, Maersk Supply Service secured a contract with Subtec S.A de C.V. of Mexico, a subsidiary of the Blue Marine Group, for one of its Stingray vessels. The designated vessel will operate in the Bay of Campeche performing general support duties, including IRM and maintenance of Pemex’s platforms as well as enhancement and well stimulation. The contract is due to commence in autumn 2018 with a firm duration until June 2020. At the time of writing the Maersk Installer was at the Singapore anchorages but her first major deployment could not be disclosed by her owners. The fourth and final vessel in the Stingray series, N453, is expected later in 2018.

TECHNICAL SPECIFICATIONS

Designer: |

Marin Teknikk, Gurskoy, Norway |

|

Keel laying date: |

9th December 2015 |

|

Launch date: |

27th October 2016 |

|

Delivery date: |

16th October 2017 |

|

Shipyard: |

Cosco Dalian Shipyard, 80, Zhongyuan Road, Dalian Bay, Dalian, China |

|

Hull No.: |

N450 |

|

Naming date/location: |

16th October 2017 at Cosco Dalian Shipyard, Dalian, China |

|

Ship Type: |

Offshore Support Vessel |

|

Classification: |

A1 Offshore Support Vessel, (Supply) BWT Enviro+, FFV 1 Helidk Ice Class IC NBLES NIBS RRDA SPS CRC(I) ACCU |

|

Owner: |

Maersk Supply Service Subsea UK Ltd., Esplanaden 50, 1098 Copenhagen, K, Denmark |

|

Operator: |

Maersk Supply Service A/S, Esplanaden 50, 1098 Copenhagen, K, Denmark |

|

IMO: |

9753911 |

|

Flag: |

Isle of Man |

|

Port of Registry: |

Douglas |

|

Gross Tonnage: |

14,908 |

|

Deadweight: |

9,788 |

|

Length Overall: |

137.60m |

|

Length b.p: |

128.05 |

|

Beam: |

27.00m |

|

Draught: |

6.20m |

|

Scantling Draught: |

8.00m |

|

Hull Depth (Main Deck): |

11.00m |

|

Hull Depth (Shelter Deck): |

13.90m |

|

Freeboard: |

3.00m |

|

Main Engines: |

4 x MaK 8M32E & 2x MaK 8M20C |

|

Generators: |

4 x Siemens 6600V 4689 kVA & 2x Siemens 6600kV 1556 kVA – Syncronous generators |

|

Propellers: |

2 x Schottel SWL420, 3,500kW each/4.00m diameter |

|

Rudders: |

2 |

|

Speed: |

14.0 knots at 5.50m draught |

|

Economy Speed: |

10 knots |

|

Bollard Pull: |

100 tonnes approx. |

|

Stern Roller: |

3.00m/50t SWL |

| Tugger Winches: | 2 x 15t |

| Tunnel Thrusters – Bow: | 3 x Schottel STT 7 FP, 2,750kW each |

|

Tunnel Thrusters – Stern: |

3 x Schottel STT 6 FP, 2,000kW each |

|

Dynamic Positioning: |

DP3 |

|

Moonpool: |

1 x 4.80m x 4.80m & 1x 8.40m x 8.40m |

|

Firefighting: |

FiFi1 system – 2,400m3/hour |

|

Stern Work Deck: |

1,925m2 |

|

Helideck: |

22m Diameter/12.6t take-off weight/CAP 437 certified. |

|

Crew/Personnel: |

120 |

|

Accommodation: |

120 single cabins |

|

Crew Facilities: |

3 x Conference rooms, 10 x Client offices, 3 x Lounges, Gymnasium etc. |

CAPACITIES |

|

|

Fresh Water: |

1,000m3 |

|

Low Sulphur Fuel: |

1,850m3 |

|

Drill/Ballast Water: |

7,700m3 |

|

Low flashpoint liquids: |

Preparations for 260m3 |

Special thanks must go to Charlotte Holst, Head of Communication, and Hayley Morgan-Palmer at Maersk Supply Service A/S, Copenhagen for the invaluable assistance with information, diagrams and images.

Comments

Sorry, comments are closed for this item