Cecon ASA is a subsea contractor involved in the fields of project management, engineering and subsea installation for the offshore oil and gas and renewables industry. Contracts are undertaken in both the SURF (Subsea Umbilicals Risers & Flowlines) and Rigid Pipeplay markets. Based in Arendal, Norway, Cecon completed its first year of business in 2005 and has since completed a range of projects worldwide, in locations such as Angola, Nigeria and The Netherlands, primarily involving the installation of rigid and flexible pipelines, umbilicals and cables. The three newbuild subsea construction vessels, the Cecon Pride, Cecon Excellence and Cecon Sovereign were subsequently ordered to form the basis of a very powerful high specification construction fleet. In addition to the pipeline projects, Cecon personnel have carried out a number of marine operation projects including heavy lifts, towing operations etc. These projects have included piling and swaging, installation of suction anchors and drag anchors, installation of chain and wires, mooring buoys, risers, templates and more besides. Cecon has been involved in a number of pipelay projects where both carbon steel and CRA materials have been used. Cecon ASA also has an operation in The Netherlands, Cecon NL BV, based in Leiden.

National Pride

In November 2012 Cecon ASA entered in to a partnership with London based operation Zafiro Marine (now Inocea) to purchase Canadian shipyard Chantier Davie Canada Inc. in the Lauzon area of Quebec, Canada. Zafiro Marine continues to operate and comprises a fleet of specialist offshore support vessels engaged in the Oil, Gas and renewable energy markets. The Davie shipyard was founded in 1825 by Allison Davie, an English ship captain. The company was established on the south shore of the St. Lawrence River across from Quebec City in Lauzon (now part of the city of Levis, Quebec). Following Allison Davie’s death, the company was headed by his wife Elizabeth Davie until 1850, when his son George Taylor Davie took the yard over as George T. Davie & Sons.

The name changed in 1914 to Davie Shipbuilding & Repairing. The Davie family sold the shipyard to Canada Steamship Lines (CSL) in 1929, however, they also started another, the George T. Davie Shipyard immediately next door to the original facility. By the 1970s, CSL was owned by Power Corporation and, in a 1976 restructuring, it sold the Davie yard to Societé de Construction Navale (Soconav) which was established by former employees of Marine Industries Ltd. with financial backing of the Quebec provincial government’s Societé Générale de Financement. In 1981 the Davie shipyard was sold to Dome Petroleum and in 1985 it was sold to Versatile Corporation which changed the name of the shipyard to Versatile Davie Incorporated.

The yard’s fortunes deteriorated and in 1986 the federal government asked Quebec to rationalise its shipyards so Marine Industries Ltd. (MIL) merged with Versatile Davie Inc. to become MIL-Davie Shipbuilding. Under this new arrangement, MIL’s shipyard in Sorel, Quebec was called M.I.L. Tracy and the former Davie yard in Lauzon was called M.I.L. Lauzon. Shortly after the merger, the new company, MIL Davie Shipbuilding closed the Sorel shipyard along with the Versatile Vickers shipyard in Montreal, resulting in a total loss of 1,700 jobs but kept the Lauzon yard open as it was working on building two large vessels for Marine Atlantic and three warships for the Canadian Patrol Frigate Project. In the early 1990s MIL-Davie Shipbuilding, along with the Davie yard in Lauzon, went into receivership. Following purchase by the Quebec government, Davie was sold to the Dominion Bridge Company for $1. In 1998, the parent of Dominion Bridge Company went into bankruptcy and the Davie shipyard went into trusteeship in 1998. It was sold again in 2000 and became Industries Davie, Ltd. During this period, the company undertook a number of projects involving vessels and rigs which serve the offshore oil & gas market. In 2006 the facility passed to TECO Maritime ASA of Norway and was restructured into a new company called Davie Yards Incorporated. In February 2010 TECO received protection from its creditors and in early 2011 Italy’s Fincantieri Cantieri Navali and subsidiary DRS Technologies Canada made a bid to purchase the shipyard from TECO. This deal fell through in July of that year and the Davie yard was restructured with its now bankrupt remains purchased by the Upper Lakes Groups Inc. that same month.

The Canadian engineering conglomerate SNC-Lavalin, Upper Lakes Groups Inc. and South Korean shipbuilder Daewoo Shipbuilding & Marine Engineering (DSME) had by this time formalised a joint venture to bid for contracts under the name Chantier Davie Canada Inc. The targeted work proved fruitless and the Upper Lakes Group’s partners withdrew so the sole owner sold the beleaguered yard to Zafiro & Cecon. Canada’s largest shipyard had at last secured a brighter future and Cecon ASA’s three-ship order, placed with the yard in 2006, was stepped up in a revival of fortunes. Having been reduced to a skeleton staff of 35 a workforce of 1000 was recalled, just under two thirds of what it had previously been. The trio of VS4220 class and DP3 capable Subsea Construction Vessels, built in partnership with Wartsila Ship Design, can undertake a range of functions including pipe laying, diving, ROV support, subsea module installation and more besides. Built to North Sea standards(NMD), the vessels are compliant with the highest level of comfort class (level 3) to ensure crew comfort. With the Dynamic Positioning III (DP3) notation, the ships are built to the highest level of redundancy providing safe operations for each vessel. Ship No.2 was allocated the name Cecon Excellence (delivery 2015) and No.3 will become the Cecon Sovereign (delivery 2016). The latter will differ by having a larger 400t active heave crane. The first ship, the 130m long, 28m beam and 14,203gt Cecon Pride was first floated in the Champlain dry dock on 19th October 2013 and she was named on 25th October when 90% complete. Sea trials commenced in 2014 and were concluded on 19th August. On 25th August Chantier Davie Canada Inc. delivered the ship, Hull 717, the 717th ship built by the yard to Rever Offshore AS/Cecon Shipping 2 AS (subsidiaries of Cecon ASA).

This was a momentous occasion as the multipurpose offshore construction vessel is reportedly the most complex commercial ship ever built in a North American shipyard as well as the largest ship fabricated in Canada in over twenty-five years. It is true to say that there are now only a handful of shipyards across the globe, mainly in Europe, capable of building a ship to this specification and with this level of technology.

New Ship, New Name, New Owner

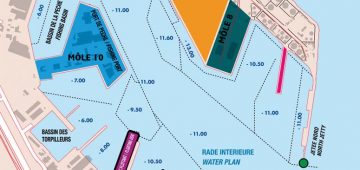

The Vik-Sandvik design VS4220 class SURF OSV Cecon Pride was originally due for an optimistic delivery date in 2009 but the shipyard’s tempestuous existence in recent years put paid to that. Three keels were left partially complete for some time until the shipbuilding version of pass the parcel concluded in 2012. A revised delivery date of February 2014 also passed by so the events of October 2014 were a huge relief to everyone concerned. To reflect a ten month bare boat charter entered in to between Cecon Shipping 2 AS (the wholly owned subsidiary of Rever Offshore AS) and Italian company Micoperi SLR, the ship was renamed Micoperi Pride upon delivery, which had been delayed. The ship sailed for the Mediterranean from the Davie Shipyard on the first high tide after the handover process was completed and reached the Mediterranean on 2nd September bound for Limassol having crossed the Atlantic. The Micoperi Pride is undertaking construction work for Italian energy group ENI. Chantier and on 28th November was noted at work in the eastern Mediterranean off Ras El-Bar near Port Said. Micoperi, based in Ravenna, Italy, is an offshore subsea contractor with a history dating back to 1946.

The company also handled the contract to recover the Costa Concordia. This OSV will operate in support of the oil and gas, renewable energy and naval sectors in Europe. No sooner had the vessel become acclimatised to her new surroundings than she found a new owner. On 15th September came the announcement that Cecon ASA, via its subsidiary Rever Offshore AS and the ship owning company Cecon Shipping 2 AS, had reached an agreement to sell the Micoperi Pride to the single purpose vehicle (SPV) FTAI Pride Inc, a company controlled by Fortress Investment Group. Fortress is a highly diversified investment manager with more than $60 billion under management. Cecon holds a minority shareholding in the buying company and will, together with Fortress, collaborate to manage the vessel and identify and secure future charters for her. The maximum cash consideration and 16.2% of the SPV taken into account give an implicit valuation of the newbuild at close to $160 million on a debt free basis. Cecon also reached the necessary agreement with York Capital, the holder of all A and B bonds for the newbuild, to align receipt of the sales proceeds with repayment of the construction financing. Cecon and its financier, which has an equity stake in the three ships ordered by Cecon, were said in 2013 to be mulling the possibility of accelerating the construction schedule to deliver the two remaining VS4220 class vessels in 2015, rather than 2015 and 2017, but delays with the Cecon Pride may have impacted upon this.

Pride in the Workplace

The 14,203gt Micoperi Pride can handle ice navigation and, vital for her subsea role in pipe laying, maintenance and SURF operations, is equipped with a Dynamic Positioning III (DP3) system. In simple terms, SURF is the engineering, manufacturing and installation of umbilicals, risers and flowlines as well as the accompanying services and is one section of the subsea industry that will play an increasing role in oil field development due to the need of activity in deeper and more hostile environments. The DP3 technology can keep the Micoperi Pride within 30cm of her required position, even in the harshest of conditions and uses seven referencing systems (2x HiPAP acoustic position/ 3x Differential GPS position/2x Taut wire position/2x Fanbeam short range laser position) which ensure the vessel’s six electrical thrusters can maintain her station. Because of the configuration of the thrusters, the vessel can move in all directions, including diagonally as well as rotating perfectly on her own axis during pipelaying, diving operations, well intervention and ROV support to name but four roles.

Hull 717 also has a fully integrated bridge system and can be controlled from thirteen locations throughout the ship including from two remote control units. Located aft are three 3000kW Steerprop SP-35CRP/W0150 azimuthing propellers that both propel the ship and assist with DP3. Two are counter rotating propellers with a 0-1,260rpm input speed. The pulling propeller diameter is 3,200mm and the pushing propeller diameter is 2,600mm. In the bow are two Brunvoll FU-100- LTC-2,750 1.5 MW variable speed/pitch transverse tunnel thrusters with a diameter of 2,750mm and 0-205rpm (for DP3 and manoeuvring in port etc) plus one 2,000kW and 2600mm diameter Brunvoll AR-100-LNC-2600 bow mounted retractable azimuth thruster with variable speed/pitch (0-300rpm). This is deployed in DP3 mode but otherwise stowed within the hull lines. Located midway along the port side of the 2,000m2 working weather deck is a Hydramarine 250t safe working load (SWL) active heave electro hydraulic crane capable of working to a subsea depth of 3000m. To assist the allweather operation the unit’s main components are located underdeck to ensure maintenance and operation in all environments.

A special nitrogen-based heave compensation system ensures that the crane hook and the load does not deviate even when the vessel is moving. The crane has a main and auxiliary winch with their maximum outreaches being 36m and 40m respectively. The crane also utilises an ultra-large 7.5m x 7.5m moonpool installed in to the working deck which allows items to be deployed and recovered through the centre of ship. A large Remotely Operated Vehicle (ROV) hangar accommodates two large, work-class ROVs which exit the vessel through sliding doors at A-C deck level. Located aft on the starboard side is a multipurpose TTS Marine GPK 1600-35-30 35t SWL electro hydraulic knuckle boom crane. As the VS4220 is a multipurpose OSV, beneath and forward of the outer deck are areas for a purpose built modular rigid pipe laying system, a 200-400t flexible lay system and a 2500t carousel, workshops etc. The diesel electric system produces 22 megawatts of power on board to supply all systems. This is generated by six General Electric 16V250 marine diesels (4,871bhp/3,632 KW each @ 900rpm) located in the hull beneath the aft section of superstructure. The main alternator is a 3.5MW Leroy Somer LSA 58 55 8P whilst emergency back-up power is provided by a 620kW MAN D 2848 LE 201 generator and a 500kW Leroy Somer LSA 50.1 VL10 alternator. Operating at sea in missioncritical roles such as those mentioned above means ensuring that in the event of any or even multiple failures, the ship will always be able to maintain her ability to hold position and manoeuvre. Every system is built with three levels of redundancy to ensure that the vessel can hold station in the event of multiple flooding, fires or machinery failures. Indeed, she boasts more redundancy than a warship. To assist with personnel transfers an aluminium 13t SWL and 22.20m diameter helideck protrudes atop the Bride Deck. This can handle some of the largest helicopters such as the Sikorsky S61N or similar.

The accommodation areas for crew and technicians are located on four levels from C Deck to the Bridge Deck. There are 40 single and double cabins on C Deck, 38 single/double cabins on D Deck plus hospital/client office and project office whilst E Deck offers Captain and Officer accommodation, offices, project library/office and an instrument room. Above here is the Bridge and atop that adjoining the helideck is the helicopter reception lounge, winch house and emergency bridge control room. The accommodation areas are outfitted to hotel standards and B Deck houses galley, mess rooms etc plus there is also an internet room and gymnasium. Offices and operations control rooms are also fitted with their own closed circuit television system controls and screens so that all areas on board the vessel can be monitored. Crew comfort is always a top priority with all working spaces being fitted with comfortable Italian leather furniture. Refreshment areas and toilet facilities are located in close proximity to every working area to ensure crew and clients can carry out their work on board the vessel with minimal disruption and in maximum comfort. Every space within the accommodation is also equipped with underfloor heating as well as its own controllable thermostat for heating and air conditioning. To assist life at sea the Micoperi Pride is even fitted with a large 8-person sauna plus several lounges.

Special thanks must go to Magnus Eilertsen (Manager, Document Control, Cecon) and Petter Hatlem (CEO, Rever Offshore AS) for their invaluable assistance with information and images.

Comments

Sorry, comments are closed for this item