SAAM Towage (Sociedad Matriz SAAM) was founded in 1961 in Chile, South America, and has grown to become a major player in the towage industry across the Americas with operational bases in Brazil, Canada, Chile, Columba, Costa Rica, Ecuador, El Salvador, Guatemala, Honduras, Mexico, Panama, Peru and Uruguay. The company operates a fleet of over 170 tugs, 35 of which have been delivered in the past 7-8 years. SAAM has involvement with the marine sectors of towage, oil and gas, salvage assistance and special services (barges and civil construction). In 2014 SAAM commenced a joint operation with SMIT Boskalis before buying the latter’s share of this operation five years later. The common trading name of SAAM Towage was launched on 30th October 2019, reflecting the adoption of a single common operating model, name and image for SAAM’s nine towage operations. The company’s growth continued with the acquisition of 70% of Intertug in 2021, entering the Colombian market, strengthening its position in the Caribbean and strengthening its regional leadership. In April 2021, SAAM Towage announced the launch of its operations in Peru and commenced operations in El Salvador, providing services to the Energía del Pacífico LNG terminal. This terminal supplies the new Acajutla LNG power station, a 378mW natural gas-fired power project constructed at the Port of Acajutla, Sonsonate, El Salvador. This is fuelled via a permanently moored floating storage and regasification unit (FSRU), an underground natural gas pipeline, a 44km-long 230kV transmission line, and three substations. Energía del Pacífico (EDP), a joint venture between the US-based power generation company Invenergy and the El Salvador-based Quantum Energy, is the owner and developer of the project. Estimated to cost £702 million, the Acajutla LNG power project represents the largest energy infrastructure investment in the history of El Salvador. Work began in 2019 with commissioning in 2021 and the site is one of the first LNG-fired power projects in Central America. Some Readers may be interested to learn that the new gas-fired power station consists of no fewer than 19 Wartsila 18V50SG/ 500rpm/18.3mW engines, each fitted with heat recovery boilers and a combined steam cycle system generating an additional 26mW using the exhaust gases from the engines. These power units are designed to operate with low-pressure gas, while the plant will be equipped with Wartsila’s Dry Flexicycle technology to avoid the use of cooling water. The entire facility will increase the electricity production capacity of El Salvador by 23% and help reduce the country’s dependence on diesel and heavy fuel oil for power generation. The LNG is delivered to Acajutla via 165,000m3 capacity gas carriers 32 times per year, which will be transferred to the aforementioned 174,000m3 FSRU for storage and re-gasification.

Newbuilds for New Venture

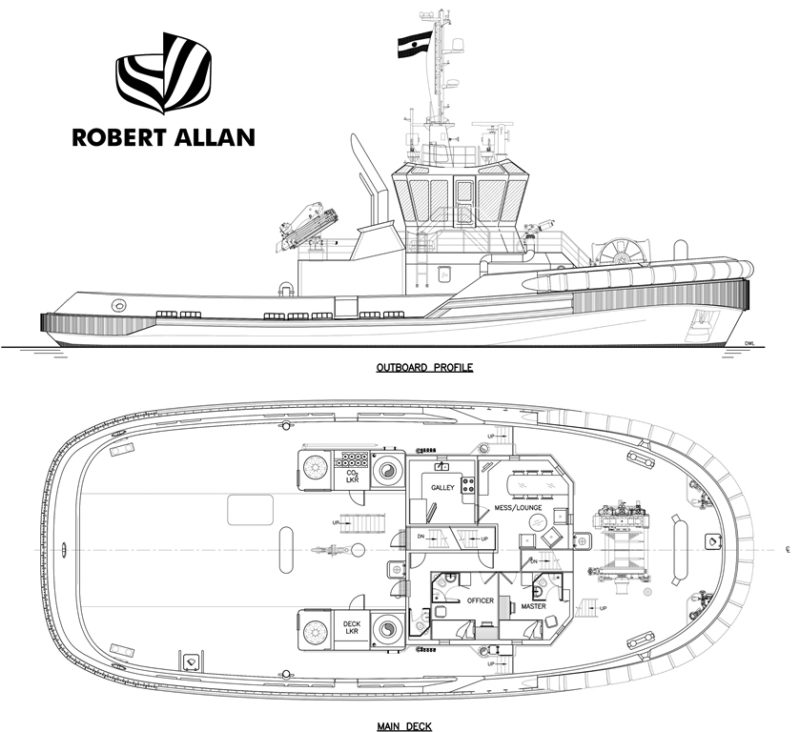

The towage duties for the Energía del Pacífico at Acajutla were awarded to SAAM Towage El Salvador S.A. with orders for two newbuild tugs being signed on 31st January 2020 with UZMAR Shipyard at Kocaeli Free Zone, near Istanbul, Turkey. UZMAR was founded in 1972 by Senior Harbour Pilot Captain Altay Altug as a pilotage and towage company and, almost 50 years later, the company provides pilotage, towage, salvage and emergency response duties at Nemrut Port, Izmit, Akcansa Port Canakkale. Ambarli Port, Istanbul and Iskenderun Port, Hatay. UZMAR has its own fleet of vessels, totalling 29 at the time of writing. In 1993 UZMAR started to build tugs for its own fleet requirements and later for the international market using the modern designs of Robert Allan Ltd. in Canada. The present modern-day facilities were established in 2005. In 49 years, the company has evolved from being the first private pilotage and towage operator in Turkey to a world-class shipbuilder, with over 200 vessels for 22 countries in 6 continents built thus far. The new vessels ordered by SAAM are 32m long ASD RAstar 3200W Class Escort Tugs designed by Robert Allan. This azimuth stern drive (ASD) class of tug was specially designed to meet the requirements of offshore operations with a bollard pull in excess of 75 tonnes and an operating speed of over 12.5 knots. The Computational Fluid Dynamics (CFD) analysis of the RAstar 3200W design tug has been completed by Robert Allan Ltd. so as to supply immense steering and braking forces when the vessels are on escort operations.

UZMAR had previously delivered a RAstar 3200W design to SAAM Towage Canada Inc. in early 2019 named SAAM Tsimshian Warrior (498gt/built 2019). This was the first IMO Tier III certified tug for Canada and she works at the AltaGas Terminal. The very first RAstar 3200 tug was delivered in February 2009 in the form of the 495gt/2009-built Monterrey for Servicios Marítimos de Baja California, S. de R.L de C.V. of Mexico. She was built by Union Naval Valencia (UNV) of Valencia, Spain with the operating company being a joint venture between Moran Towing of the USA and Grupo Boluda of Spain. The tug was the first of 4 expressly designed to work at the Costa Azul LNG terminal on the north-west coast of Mexico, a terminal exposed to fully developed Pacific swells. The basic requirements for the tug design stipulated that the tug and winch must be able to sustain a line pull of 75 tonnes throughout the entire terminal approach in a 2m plus significant swell. The RAstar 3200 Class produces tugs of under 500gt with a minimum bollard pull of 75 tonnes. In order to cope with the predominant sea conditions on Escort Tug duties, Robert Allan Ltd. chose to utilise the then new RAstar hull form for the best sea-keeping. The gross tonnage constraint of 500gt forced some minor modifications to the 3200 Class concept, and also required a shortening of the forecastle. The basic hull form reflects the double chine form that characterises all Robert Allan Ltd. designs, with a sweeping chined stern. A large escort skeg is fitted forward which, in conjunction with the sponsoned hull shape, enhances the indirect towing capability and provides much enhanced roll stability. On trials the Monterrey performed exceptionally well, achieving a mean bollard pull of 82.5 tonnes and a free-running speed of 14 knots.

Speedy Delivery

The two tugs destined for El Salvador had their keels laid on 6th April and 15th May 2020 respectively, were launched on 10th November and 11th December 2020 with delivery being instigated on 9th March 2021. The duo was placed into the hands of Dutch company Redwise Maritime BV, an outfit that specialises in delivering newbuilds around the globe from shipyard to Owner/Operator. The tugs departed from the port of Izmit (Turkey) on 12th March and, on 21st April, the arrival of the vessels at the Port of Acajutla was announced following a 40-day voyage across the Atlantic Ocean and through the Panama Canal.

The tugs carry the names SAAM Acaxual and SAAM Centzunat, names from the native language Nahuatl in El Salvador, meaning Acajutla and Sonsonate (the region where the port is, meaning Big River/Four hundred waters).

These robust 32m long RAstar 3200W tugs have a 13.20m beam, a hull depth of 5.50m, a draught of 6.20m, a deadweight of 315 tonnes and a maximum displacement of 950 tonnes. Each vessel’s deckhouse has been outfitted to the highest standards for a crew of 5-7. The main deck features generous en-suite cabins for the Master and Chief Engineer, both with en-suite facilities, and a spacious crew mess/lounge, served by a fully equipped galley. The lower deck contains three en-suite crew cabins, two of which are equipped for double occupancy. The remainder of the lower deck space is dedicated to stores spaces, the laundry, HVAC and Switchboard rooms. The wheelhouse is designed for maximum visibility with a single control station providing maximum visibility to both fore and aft deck working areas. Low noise levels throughout the accommodation and control spaces of the tug are achieved by utilising advanced methods of isolating main propulsion machinery, as well as high-grade insulation and floating floor techniques. B

Beneath the Lower Deck are fuel and fresh water tanks plus the domestic/auxiliary machinery space. Midships in the hull is where the “business end” of the tugs can be found. Power is provided by two Caterpillar 3516C V-16, 4-Stroke Water-Cooled Diesel engines. These robust units have a 170mm bore, a 215mm stroke and a compression ratio of 14.7:1.

Engine output per unit is 2,350kW (3,150bhp) @ 1800 rpm and each 3516C drives a Kongsberg (formerly Rolls Royce) US 255S P30 fixed pitch azimuthing Z-drive propeller with a diameter of 2,800mm. The 255S propeller units have a maximum output power of 2,600kW, an input power range of 750-1,800rpm, a stem length from the hull of 3,600-3,800mm and weigh 25-30 tonnes. A free-running service speed is provided and, with a bollard pull of 81 tonnes, these tugs can work under dynamic traction loads of more than 135 tonnes at a speed of 10 knots. The design steering force at 10 knots is 86 tonnes and the design braking force at 10 knots is 129 tonnes. The electrical power on board is supplied via a pair of Caterpillar C7.1 ship service generator sets, 118ekW @ 60 Hz each plus one Caterpillar C4.4 harbour generator set, 44 ekW @ 60 Hz. Firefighting capability is a Fi-Fi 1 class system with water spray, supplied by Marsis, featuring two 1,200m3/hr water monitors with foam capability (300 m3/hr). The system is supplied via a 2,750m3/hr pump driven by a dedicated CAT C32 engine, 1,193 kW @ 1800 rpm. Specific safety features onboard include a remotely operated gas detection and automatic isolation system, plus deck equipment and machinery with explosive atmosphere certification (ATEX).

Deck machinery on the SAAM Acaxual and SAAM Centzunat includes an escort (bow) winch (hydraulic), DMT model RRW-H800kN, 800 kN @ 0-10m/min pull, 2700 kN brake, spooled with 2 x 220m of 72mm synthetic line over 7 layers, ATEX Zone 2 rated plus two vertical windlasses (hydraulic), DMT model ACH-22K2, ATEX Zone 2 rated and a towing hook with quick release, Data Hidrolik model DTH 90-135P. A Palfinger PK23500(M)A folding knuckle boom crane, 1.85t SWL @ 8m outreach, is fitted on the port side aft of the superstructure for general purpose use. The aft deck provides a clean and spacious working area.

Onwards and Upwards

SAAM Towage admitted that completing these sister vessels was an enormous challenge due to the complications presented by the pandemic, but each hurdle was navigated and the project remained on schedule. The arrival of the RAstar 3200W newbuilds in April coincided with SAAM Towage commencing a new operation in Peru. To undertake this, a tug was redeployed to the Port of Callao with a second being delivered in the form of the 312gt/2021-built Albatros from Sanmar Shipyards in Turkey. Built as the Bogacay XLII, the Albatros is a 24.4m long Robert Allan RAmparts 2400SX design workhorse with a beam of 11.25m. She is powered by two 2,100kW main engines, providing a running speed of 13 knots and 70 tonnes of bollard pull. Fire-fighting equipment is also fitted, driven through a clutched flexible coupling in front of the port side main en

gine, with capacity to deliver 2,700m3/hr of water and foam. Earlier in 2021 SAAM Towage also expanded services in Ecuador with two more tugs built to handle larger ships. The first of these, the Ramparts 2500W design SAAM Tarqui (365gt/built 2016), arrived at the port of Guayaquil on 26th January after her long voyage from Med Marine, Turkey. This example was previously known as the Efesan Port, and was later joined by another tug from Mexico.

Comments

Sorry, comments are closed for this item