Svitzer Towage is a global brand with a history that began in 1833 when the salvage company Em. Z. Svitzers Bjergningsentreprise was established. The founder, Emil Zeuthen Svitzer, was an entrepreneurial tradesman who saw the potential of establishing a salvage business on the basis of the many unfortunate losses occurring on trade routes to and from Denmark. The company has been part of the Maersk Group since 1979 and boasts over 180 years of running a towage and salvage company with operations all over the world including across Europe, South America, Mexico, U.S.A, Canada, Angola, Australia, Singapore and Oman. Overall, the company has in excess of 430 vessels operating from over 100 locations and around 20 oil terminals across the globe. As of 11th November 2019, Svitzer added the Suez Canal Container Terminal in Port Said, Egypt to its sphere of operations after signing a 10 year agreement with the Suez Canal Authority (SCA) in March of that year to deliver two 70tbp ASD tugs to provide towage services at the Suez Canal Container Terminal (SCCT), which is operated by APMT, in Port Said. The first vessel, the 492gt/2019-built and 32m long Svitzer Port Said 1, an RAstar 3200 CL tug, went on duty on 11th November while the second, the 492gt/2019-built sister vessel Svitzer Port Said 2, arrived in January 2020. These tugs have Schottel SRP 490FP propulsion. The initial volume of 10 tug jobs per vessel per day was expected to double with the jetty extension at Port Said. Svitzer had already been successfully operating in Egypt at the Idku LNG plant since 2005 under a 20-year contract with Egyptian LNG and the Suez contract was Svitzer’s second operation in the country. On 11th August 2021 Svitzer announced that it had extended its current contract with the Suez Canal Authority to include two additional tugs. Whilst the initial tugs had been based at the Mediterranean entrance, Port Said, since 2019, the new vessels would be based at the Red Sea entrance to the canal at Port Suez. The new tugs were newbuilds delivered from the Cheoy Lee Shipyard and manned by all Egyptian crews. Operations were planned to commence in the fourth quarter 2021. The expansion of the SCA tug fleets was at least partially influenced by the extraordinary incident involving the 22,940gt/2018-built and 20,124 TEU capacity containership Ever Given, which ran aground in the Suez Canal on 23rd March 2021 whilst en-route from Tanjung Pelepas in Malaysia to Rotterdam in The Netherlands. The ship was stuck fast and remained in situ for 6 days before salvage crews freed her on 29th March 2021. The incident highlighted a number of areas for improvement including the need for additional support vessels for canal traffic.

FIRST IN CLASS

The new tugs earmarked for the Port Suez contract were the first examples of the all-new RAstar 2800-CL ASD escort tug, designed by Robert Allan Ltd. of Canada and built by Cheoy Lee Shipyards, located 45 miles west of Hong Kong, China, a company with over 100 years and five generations of uninterrupted shipbuilding. The shipyard can trace its routes back to the 1870s although it was in 1936 that the family business moved to the then British colony of Hong Kong, marking the start of the Cheoy Lee Shipyards that we know today. Initially specialising in mechanising sail powered cargo vessels during World War II, by the mid-1950s Cheoy Lee had diversified into the production of teak sailing and motor yachts, mostly built for export to America. Come the 1960s, this now burgeoning pleasure craft division of Cheoy Lee accounted for 90% of all production from the yard. Expansion of the shipyard was required, and it was at this time that the Penny’s Bay site in Hong Kong was established. As a pioneer in the development of fibreglass as a boat building material, Cheoy Lee recognised the savings in weight, greater strength and longevity that this new material offered.

Constantly investing in research and improving production techniques, Cheoy Lee honed their fibreglass capabilities to become a forerunner in the marine use of GRP (and foam sandwich) construction. In 1977, Cheoy Lee built the world’s largest moulded fibreglass yacht of its time, the Shango II. At the end of the 1990s, Cheoy Lee relinquished the Penny’s Bay site that had been home for some 35 years, to take advantage of the skilled and competitive labour that existed just across the border in Zhuhai, China. The Penny’s Bay site was transformed into what is now Hong Kong Disneyland. Cheoy Lee is a prominent commercial vessel builder with tugs being a major source of work. Several examples from the numerous classes of the impressive Robert Allan Ltd. range of tug designs have been built here and delivered around the world.

The Canadian Naval Architect company of Robert Allan Ltd. was founded in 1930 when Robert Allan commenced private practice as a consulting Naval Architect after serving as Technical Manager of a local major shipyard. Robert F. (Bob) Allan joined his father in the practice in 1945. The business grew steadily and was instrumental in the development of specialised tugs and barges for the burgeoning forestry and mining industries along the B.C. coast, and for many unique shallow-draught vessels for Canada’s remote Northland. Incorporated as Robert Allan Ltd. in 1962, the company continued to expand and achieved international recognition for the high standards and performance of its many unique and specialised designs. In 1973, Robert G. (Rob) Allan joined the company, following the family tradition. In 1981 he succeeded his father as President, leading the company into a new generation of computer-based design technology. Today, a vessel is built to one of Robert Allan Ltd.’s designs somewhere in the world almost every week.

The Svitzer Suez 1 became one such example on 27th October 2021 when she was delivered to Svitzer as the very first RAstar 2800-CL ASD design. Svitzer were the first owners of this new breed of escort tug with a further 9 sister tugs to this design having already been ordered from the Cheoy Lee Shipyard. The RAstar 2800-CL design started with a “blank sheet of paper” with one of the primary goals of the design being to make it extremely flexible, allowing for various propulsion machinery options, IMO Tier III solutions, deck machinery choices, accommodation layouts, etc. all with minimal impact on the overall design. This was to allow Cheoy Lee to easily offer customised solutions to clients even at a relatively late stage in the construction process. The hull form has the proven sponsoned shape typical of all RAstar designs and was refined and tested using CFD to ensure the desired free running performance, manoeuvrability, and escort performance characteristics. The escort performance was analysed using CFD at various stages of the design to ensure the desired escort performance while achieving a design that is fully compliant with IMO escort stability criteria at speeds up to 10 knots. The deckhouse has a low profile for working under the flared bow of attended vessels and visibility from the operator’s position is excellent. Design work was completed to ensure compliance with all the major classification societies, and it exceeds many flag and/or owner specific safety requirements such as being fitted with 45 degree stair angles throughout. The 433gt/2021-built Svitzer Suez 1 is 28.40m long with a 13.00m moulded beam, a hull depth of 5.40m, a maximum draught of 5.50m and has a deadweight of 222dwt. The vessel began life as Yard No. 411 and has a net tonnage of 129.

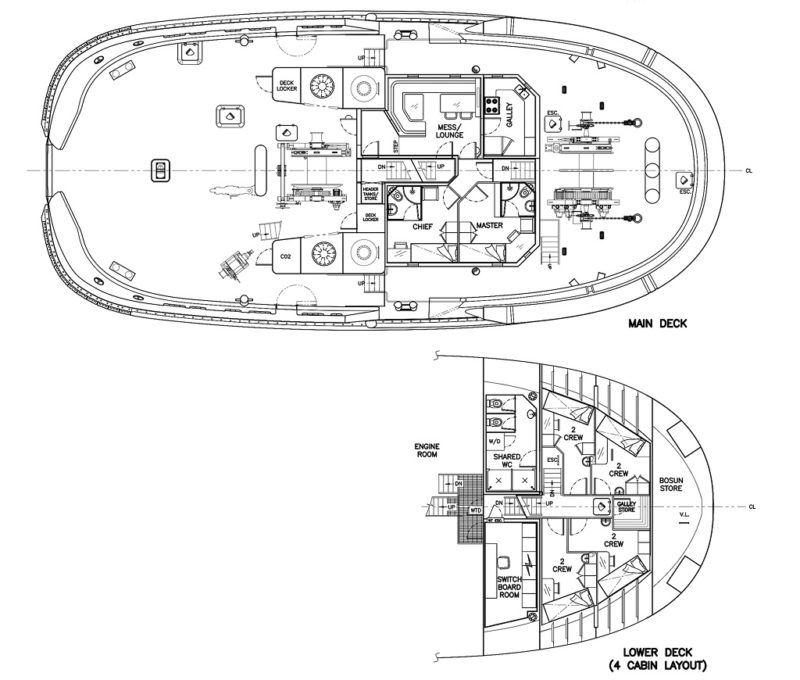

As with all Robert Allan Ltd. products, the accommodation is outfitted to high, MLC compliant standards for a crew of up to 10 personnel. The Master and Chief Engineer cabins are located on the main deck with four double crew cabins located in the lower accommodation area, positioned forward in the bow. The tug’s main propulsion comprises a pair of CAT 3516C diesel engines, each rated at 2350kW at 1800rpm, with each driving a Kongsberg US 255S P30 Fixed Pitch Z-drive. The installed power produces an ahead bollard pull of 82.1 tonnes, an astern bollard pull of 77.6 tonnes and a service speed of 13.3 knots. The CAT 3516C is a 78.08 litre engine with a 170mm bore and a 215mm stroke. The dry weight is 10,447kg with each unit being 1,184.5mm long and 2,129.6mm high. The Kongsberg 255S azimuthing units are available with a 2,500mm or 3,000mm diameter propeller, a stem length of 3,600mm/3,800mm and each weigh 25t-30t depending on type. Onboard power is provided by 2 Caterpillar C 7.1 diesel generator sets, each with a power output of 118ekW.

The Svitzer Suez 1 boasts various deck equipment including a MacGregor MG-HAET/GDG-22-1224U02060 x 2-BL hydraulically driven, split drum, escort towing winch on the foredeck. This accommodates 2 x 200m lengths of 60mm diameter synthetic rope and is fitted with double gypsies and warping heads. The winch is equipped with a length and tension monitoring system with load indicating display in the wheelhouse. First layer low speed pull is 120t @ 5 m/min. and high-speed pull is 5t @ 80 m/min. First layer pay-out is 144 tonnes @ 5 m/min. and 36 tones @ 18 m/min. The brake holding force of the winch is 240 tonnes.

On the aft deck is a MacGregor MG-HTW1-0220D07556-BL hydraulically driven towing winch. The drum can accommodate 750m of 56mm diameter steel wire rope and has a brake holding force of 200 tonnes. First layer low speed pull is 20 tonnes @ 15m/min. and high-speed pull is 8 tonnes @ 30m/min. The winch has a spooling gear and a 530mm diameter horizontal warping head. The aft deck is further outfitted with a gob eye, tugger winch, rescue boat, and knuckle boom crane. The vessel is also equipped with an off-ship fire-fighting system meeting class Fire Fighting Ship 1 requirements with water spray. The system was supplied by Fire Fighting Systems and comprises one main engine driven centrifugal pump type FFS SFP 300 x 400 XPC with capacity of 2,850m3/hour. The two monitors deliver 1,200m3/hour of water and 300m3/hour of foam.

Ship handling fenders at the bow consist of an 800mm diameter cylindrical fender with 480mm x 300mm “W” block fendering below. Further 300mm x 300mm hollow “D” fendering provides protection at the sheer line, and 480mm x 300mm “W” block fendering is used at the stern. Sister vessel Svitzer Suez 2, IMO 9892925, was delivered on 4th November and joined her sister at Port Suez.

BUILDING FOR THE FUTURE

Robert Allan Ltd. and Svitzer signed a design agreement in November 2021 for a new generation of methanol fuel cell tugs. Utilising a combination of fuel cells, batteries, and electric propulsion in a new and unique towing configuration, this new breed of tug will serve as a pilot project for future Svitzer newbuilds. The close co-operation between Svitzer and Maersk will allow for the transfer of knowledge and experience from the small scale of inshore tug operations to ocean going containerships. As the designers of the world’s first hybrid tug, Robert Allan Ltd. has been at the forefront of ‘green’ technology for more than a decade, continually pushing the boundaries of new technologies to provide customers with innovative and environmentally friendly alternatives to conventional diesel-mechanical powertrains. This new project, a bold step forward, once again validates Robert Allan Ltd.’s position as a world leading tug designer.

The following month, the two companies signed a deal to design and build a new Transverse Tug design that incorporates several unique elements and combines them in a package that promises to be safer and more efficient. Working under guidance from Svitzer’s teams from Technical Innovation, Projects and Engineering, and Marine Operations, an extensive tank testing programme has been conducted at HSVA, Hamburg. Several iterations of propulsion layout, appendages and towing arrangement were tested in various operating scenarios and the final layout was selected based on optimal performance, controllability, and safety. CFD validation of performance has been conducted by the hydrodynamics team at Robert Allan Ltd. and the results corroborated with the model testing. Robert Allan Ltd.’s ability to provide unique, flexible and innovative engineering solutions during the early design phases was a key factor in developing a tug that is exclusively customised to Svitzer’s requirements. Leading tug builder, Sanmar Shipyards of Istanbul, Turkey has been selected for the construction, and the nature of such an advanced and contemporary project will no doubt present many challenges and opportunities during the build process. Robert Allan Ltd., Svitzer and Sanmar have a proven history of co-operation on tug building projects and this latest collaboration will only serve to strengthen this relationship. As they say, watch this space.

Comments

Sorry, comments are closed for this item