There has been a vehicle ferry service operating between Portsmouth and Fishbourne, Isle of Wight, since 15th March 1926 when the 6-mile route (which is subject to low tide diversions around Spitbank Fort) opened for business. The route was transferred to Wootton Creek by the Operator, Southern Railway, from a berth by Ryde Pier that was subject to considerable tidal restrictions. The primitive tow boat service was transformed into a Ro-Ro service using the small, 15 car capacity Denny built Fishbourne, Wootton and Hilsea built 1927-30. The route went from strength to strength through the Sealink and Sealink British Ferries eras with the Operator changing to Wightlink in 1990. By 2001 a dozen vehicle ferries had been built for the service.

New Era, New Build

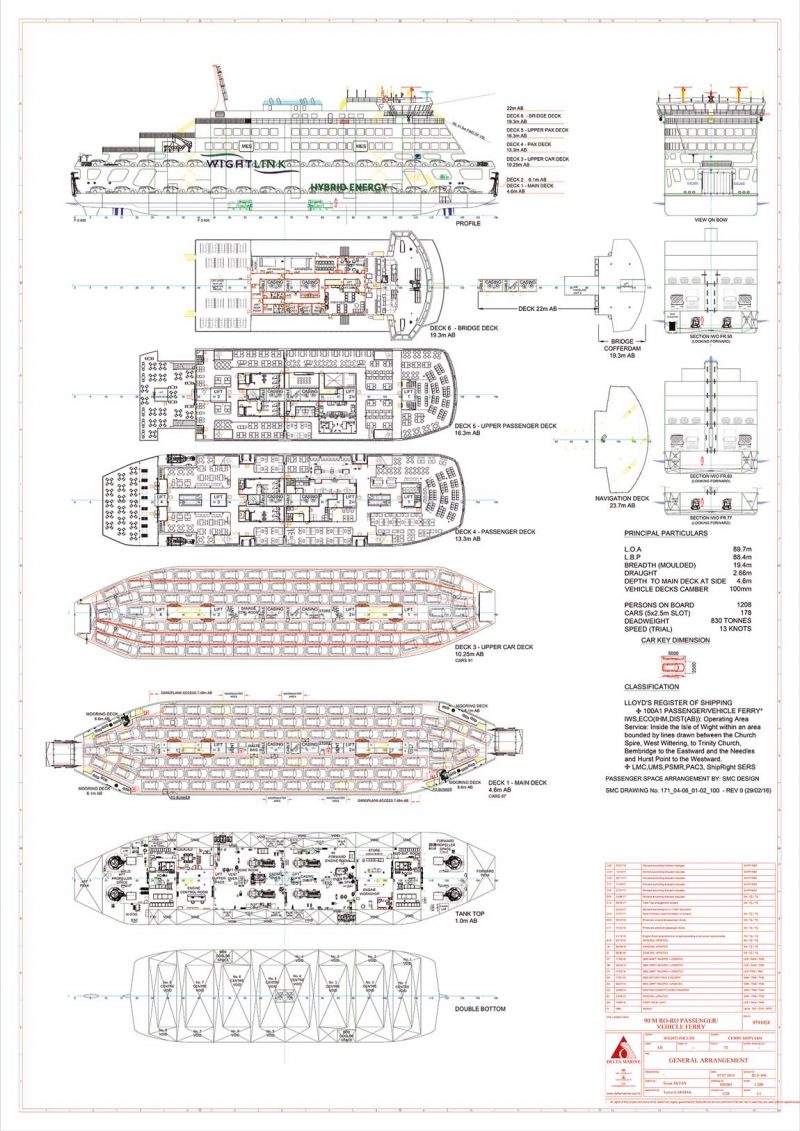

On 28th April 2016 Wightlink signed a contract in the region of £30 million for the building of a new ship that would be the most environmentally friendly ever to serve the Isle of Wight with delivery scheduled for 2018. Designed by Houlder, the new flagship was to be larger than the 5,952gt/2001 built St. Clare and built to the maximum footprint possible for a ferry using the confines of the Camber Docks in Portsmouth. Hybrid battery technology would also be used on a cross-Solent ferry for the first time as well as conventional marine gas oil for a diesel electric system to reduce emissions and make the vessel quieter. The newbuild was part of an overall £45 million project to upgrade the company’s gateway route to the Island and included the provision of two-tier linkspans at both terminals, an upper level marshalling area and new customer services building at the Portsmouth Gunwharf terminal, new mooring technology and the conversion of the routes incumbent flagship, the St. Clare, to double deck loading/unloading, something her design had cried out for from delivery. The contract to build the new ship was awarded to the Cemre Shipyard in Yalova, Turkey, an establishment known for ferry, Ro-Ro and specialised newbuilds.

More than 50 shipyards around the world, including the UK, were invited to bid for the building contract. Wightlink received 22 tenders and shortlisted five yards from Turkey, Spain and Croatia before choosing Cemre on the Sea of Marmara, at Yalova, south of Istanbul. The decision was made on the grounds of value for money and the capacity to deliver the vessel within two years. No U.K based Shipbuilder was able to build such a ferry in the timescale or to the required budget. Indeed, there was little home-grown interest in the contract but of course there was an outcry as to why Wightlink did not use a British yard, something that rattled on even beyond the arrival of the ferry at her new home. Cemre was established in 1996 as a site for repainting works, ship repair and scraping activities. In 2005 Cemre leased an area from the Pendik Military shipyard in order to develop the company and subsequently entered the shipbuilding industry. The first ship to be built was the Havila Mars and she was delivered to the Havyard Grup A.S. in 2006. In 2008 Cemre’s own shipyard was founded in Yalova in the Altınova shipyard region, which is the hub of the Turkish shipbuilding industry. A 10,000m2 workshop was established 500m away from the shipyard and the general shipyard site grew to an area of 70,000m2. The first ship to be delivered from the new site was the Havila Jupiter. A 7,000m2 indoor hangar was added in 2011 and in 2012 two new slipways were completed in order to increase annual shipbuilding capacity. In 2015 a further 65,000m2 was added to the shipyard site.

Cross-Solent Royalty

The steel cutting ceremony to signal the start of the construction process for Yard No. NB52 took place on 4th October 2016 in Yalova. The new ship was initially dubbed the G-Class by Wightlink but this was later modified to H-Class as in H for Hybrid. Sections of the ship were then fabricated with the keel laying taking place in November 2017. NB52 quickly took shape and, at 1150 local time on 7th February, the new ferry was launched down the slipway to cheers from Wightlink staff and hundreds of shipyard workers. Wightlink’s Project Manager, John Burrows, cut the ribbon to signal the launch. By this time Wightlink had held a competition for staff to decide on the name of the new ferry.

Five suggested ‘Victoria’ in honour of Queen Victoria who loved the Isle of Wight, with her Island residence of Osborne House being just along the coast from Fishbourne at East Cowes. As the name Victoria was already in use on another ship, the variant Victoria of Wight was chosen instead. So, complete with a striking “Hybrid Energy” variation of the company livery, the Victoria of Wight took to the water draped in the national flags of Turkey and Great Britain. The fitting out process continued and, on 12th June, it was revealed that the ship had impressed during her first 3 days of sea trials in the Sea of Marmara. Tests completed included the hybrid system, full speed trials, manoeuvring, the deployment of one of the ship’s four marine evacuation systems and the car deck drenching system.

She’s Coming Home

As the 89.70m long, 19.40m beam, 2.66m draught and 8,041gt Victoria of Wight was specifically designed to operate to and from the Isle of Wight, a route where no crew are required to sleep on board, the ship was to be towed to Portsmouth instead of making the journey under her own power as the ship has no facilities to allow crew to live aboard for 2-3 weeks.

Following official handover to Wightlink on 11th July, the Victoria of Wight set off from Yalova on the evening of 16th July for her 3,019 nautical mile voyage home to Portsmouth. She was towed by the 975gt/2007 built Amber II at a sedate pace of around 6 knots through the Sea of Marmara, past Gallipoli through the Dardanelles (where a second tug assisted at the stern of the new ferry), then westward through the Mediterranean passing Greece, Sicily and Spain before turning north at Gibraltar to sail along the Portuguese coast, across the Bay of Biscay and into the English Channel.

Weather conditions caused delays in progress off Catania, Italy and shelter was also taken off Faro, Portugal, until sea conditions abated. These occasions probably added around 4 days to the voyage. An image showing the small assisting tug at the stern of the ferry on Social Media prompted a deluge of questions as to why the ship was being towed backwards! This rumbled on almost as long as the “why wasn’t the ship built in the U.K” saga. However, the ensemble arrived off the South Coast on 9th August, sheltering for much of the time in Poole Bay, before heading around the south of the Isle of Wight and entering Portsmouth Harbour from Nab Tower in appalling weather conditions late morning on 10th August. The ship was boarded by her Captains, some crew and a Pilot off Outer Spit Buoy for the homecoming. Assisted by the SMS Towage tugs Guardsman (188gt/built 1991) and CMS Warrior (161gt/built 2015), the ship tied up on the Hulk Moorings in the harbour. On the morning of 12th August, the Victoria of Wight set out for the first time in home waters under her own power for sea trials and berthing trials at Fishbourne and then Portsmouth. A low-key entry into revenue earning service came on 26th August when the Victoria of Wight made an unscheduled 10.30am departure from Portsmouth Gunwharf and an 11.30am return from the island. This went without a hitch and a 5 round trip diagram was operated the next day, the August Bank Holiday Monday. Regular service for the new girl was expected from around mid-September when more of the 11 crews had been trained and the naming ceremony took place at Fishbourne on 20th September when HRH Sophie, Countess of Wessex, did the honours.

VoW causes a WoW

Representatives of the local Media were invited aboard the Victoria of Wight at the Camber layby berth in Portsmouth on 17th August allowing the Writer’s first look at this impressive ship. The travelling public had their first taste of the new era on 26th August and the reaction of the majority as each passenger entered the accommodation areas was “wow!” The new H-Class ship takes several influences from the ever-popular Saint Class including the prow flap design from the St. Catherine, the conventional single-ended format and the central casing on the vehicle decks. The latter provides more deck space and allows three 2.5m wide lanes along each side on both the main vehicle deck (Deck 1) and the upper vehicle deck (Deck 3). Deck 1 can accommodate 87 cars or 14 articulated HGVs and Deck 3 has space for 91 cars. The vehicle capacity is based on a Car Equivalent Unit (CEU) being 5m long in a 2.5m wide lane. There are no mezzanine decks. Upon boarding the ship the sheer size of the car decks cannot be overlooked. Deck 1 is accessed via hydraulically operated two-piece prow ramps (approx. 5m wide each) and Deck 3 is accessed via similarly wide aprons with manually operated gates at either end of the deck. To fit the existing berths the Victoria of Wight’s design is asymmetric, especially noticeable when you look at her bow or stern on. The prow ramps are offset accordingly and the starboard side of the superstructure also differs slightly in profile to the port side. The bridge however is located centrally. Decks 4 and 5 offer 500m2 of passenger accommodation to a level of comfort and luxury not previously seen aboard a Cross-Solent car ferry. Overlooking the bow in both lounges are 6 rows of seating offering panoramic views. Several varieties of individual, at-table and sofa seating in a pleasing array of pastel colours can be found on both levels. On the port side of Deck 4 is the Wight Taste food and drink outlet plus there is also a reception area, toilets, medical room and the aft lounge area offers pet friendly seating. The Deck 5 lounge is slightly shorter but the layout largely mirrors that on Deck 4. This level also has the Kid’s Play Area and Cinema on the port side, the Costa Coffee outlet on the starboard side and toilets. LED mood lighting is located in the ceilings on both decks. Waste heat from the engines is used for heating and excess energy generated by the four eco-efficient passenger lifts is harnessed for the ship’s electrical supply. Together with motion-activated LED lighting, such initiatives lead to a significant reduction in the ferry’s carbon footprint. The passenger area flooring is a mixture of laminate and colourful carpeting. The 550m2 of promenade deck is located aft of the passenger lounges plus on Deck 6. Indeed, the raked stern decks give the impression of being aboard a cross-channel ferry. Talking of which, the ship’s navigation bridge, also on Deck 6 forward of the crew area (Mess Room, Conference/Training Room & Ship’s Office) is comparable in size to a channel ferry and is most impressive. From the bridge the ship’s four Voith Schneider 21R5/150 units (two forward/two aft) can be controlled from the Captain’s chair or bridge wings via joysticks or from a centrally located standard two-wheel control console. The Damage Control Room for emergencies is located on Deck 3. The “business end” of the ship is of course below decks in the machinery spaces.

The two engine rooms are located centrally within the double-bottomed hull and both contain two 6-cylinder Wartsila 6L20 marine diesel generator engines that each develop 1200kw @ 1000rpm and run on marine gas oil. Astern of the aft engine room is the Engine Control Room and an office. Adjoining this area is the aft battery and switchboard room. Next to the forward engine room is a workshop and stores and forward from here is the forward battery and switchboard room. The propulsion system is diesel electric so there is no need for drive shafts.

This newbuild is the first to feature Wärtsilä’s hybrid battery technology to improve efficiency, reduce exhaust emissions and lower noise levels. The package installed also includes electrical and automation (E&A) systems and a sanitary discharge system. Among the E&A systems supplied are an integrated automation system (IAS), a power and energy management system (PMS/EMS), and a 690V main switchboard.

The hybrid system enables a significant energy improvement over conventional systems by running the engines at optimal load whilst absorbing many of the load fluctuations using batteries, known as peak shaving. Wärtsilä’s Orca Energy energy storage system (ESS) is also installed. Supplied by Corvus Energy, the two 405kw battery packs are designed to smooth out power demands to maintain economic operation of the engines. The stored energy is used to increase the required power in an instant without increasing the engine load. The batteries are then replenished from excess energy generated during normal operation.

Port arrivals and departures can be completed solely on battery power when conditions dictate with one or more generators recharging the cells. The four Voith Schneider propellers are the same as those installed on the St. Clare and the three 2,546gt/2008 built W Class ships. The only difference is that the blades are 1500mm long compared to 1350mm on the other vessels. The Victoria of Wight has more than 146km of cable, weighing 76 tonnes, aboard and almost 30,000 litres of paint were used to paint her.

Special thanks must go to John Burrows (Operations Manager, Wightlink Ltd.) and Karen Woods (Media Relations, Wightlink Ltd.) for all the invaluable help with information, images and diagrams.

Technical Specifications

| Designer | Houlder |

| Passenger Space Design | SMC Design |

| Shipyard | Cemre Shipyard |

| Location | Yalova, Turkey |

| Yard No. | NB52 |

| IMO No. | 9791028 |

| Operator | Wightlink Limited |

| Flag | United Kingdom |

| Port of Registry | Portsmouth |

| Service | Portsmouth-Fishbourne (Isle of Wight) |

| Ordered | 28th April 2016 |

| Keel Laid | November 2017 |

| Launched | 8th February 2018 |

| Sea Trials | June 2018 |

| Delivered | 11th July 2018 |

| Service Debut | 26th August 2018 |

| Christened | 20th September 2018 |

| Ship Owner/Manager | Wightlink Ltd., Gunwharf Terminal, Gunwharf Road, Portsmouth, PO1 2LA, United Kingdom |

| Type | Ro-Ro Vehicle & Passenger Ferry |

| Classification |

Lloyd’s Register of Shipping 100A1 Passenger/Vehicle Ferry* IWS,ECO(IHM,DIST(AB)) |

| Operating Area Service | Inside the Isle of Wight within an area bounded by lines drawn between the Church Spire, West Wittering, to Trinity Church, Bembridge to the Eastward and the Needles and Hurst Point to the Westward. LMC,UMS,PSMR,PAC3, ShipRight SERS |

| Gross tonnage | 8,041 |

| Deadweight | 830 |

| Net tonnage | 2,550 |

| Length overall | 89.70 m |

| Length b.p. | 88.40 m |

| Beam (Moulded) | 19.40 m |

| Hull depth | 4.60 m (to main deck) |

| Hull draught | 2.66 m |

| Service Speed | 13 knots (trials speed) |

| Passenger Capacity | 1,176 passengers (1,208 maximum) |

| Car Capacity | 178 (based on the CEU size of 5m long with 2.5m lane width) |

| Main Deck | 87 |

| Upper Deck | 91 |

| Truck Capacity | 14 (Main vehicle deck) |

| Lane width | 2.50m (cars) |

| Lifts | 4x Passenger + 1x Service Lift |

| Crew | 13 (Mode 11 – 11 + 2 coffee shop personnel) |

| Crew Cabins | 0 |

| Crew Facilities | Mess Room, Conference/Training Room & Ship’s Office – Deck 6 |

MACHINERY |

|

| Main Engines | 4x Wartsila 6L20, each developing 1200kw @ 1000rpm. |

| Hybrid Power | 2x banks of batteries, each producing 405kw, located forward and aft |

| Power Output | 4,800kw (main engines) & 810kW (battery banks) |

| Propulsion System | Diesel Electric |

| Propulsion | 4x Voith Schneider 21R5/150 units |

| Fuel | Marine Gas Oil |

Comments

Sorry, comments are closed for this item