Turning the spotlight onto the marine industry in the UK once again, the Chartwell 24 Crew Transfer Vessel was initially introduced to the working vessel scene in September 2018 when the design was launched commercially having been developed over a period of 10 years from data analysis and experience in offshore wind vessel design, alongside extensive dialogue and collaboration with CTV operators, wind farm owners and turbine manufacturers. This versatile craft was designed by Chartwell Marine and is available in two different variants, a 24.4m-long maximum length version and a 19.8m-long version that is compliant with legislation protecting the migration route of the protected Right Whale. The vessel design also underwent rigorous and scientific testing, which was conducted by Seaspeed Marine Consulting. The tests, including computational fluid dynamics (CFD) modelling and 1:12 scale model tank testing, helped in validating the sea-keeping performance, stability and manoeuvrability of the vessel. The first Chartwell 24 delivered was Seacat Service’s 111gt/2020-built Seacat Weatherly, followed by the 110gt/2020-built Seacat Rainbow, having been ordered in April & July 2019 respectively. In December 2019, Atlantic Wind Transfers signed a contract with Chartwell for two Chartwell 24 vessels for delivery in 2020-2022, constructed by Blount Boats, a shipyard on Rhode Island in the USA (built in the U.S to comply with the Jones Act). A further vessel was added for 2023. The first of these, the waterjet propelled Atlantic Endeavor, was delivered on 1st January 2021 with both vessels being of the specialised 19.8m model to conform with the American environmental and USCG regulations and legislation protecting the Right Whale. The vessel was put to work at the Dominion Energy Coastal Virginia Offshore Wind Farm to support two Siemens Gamesa turbines. The project is located 27-miles off Virginia Beach. Chartwell Marine then entered a partnership with BAR Technologies to develop next-generation offshore wind CTVs in May 2020, working on the development of 30m CTVs and 60m service accommodation and transfer vessels (SATVs) while also integrating BAR’s foil optimisation and stabilisation system (FOSS) into the Chartwell 24 CTV to improve its sea-keeping capability and manoeuvrability. On 1st July 2020 came a contract to design and build a new hybrid Chartwell 24 CTV for High Speed Transfers (HST). Diverse Marine in Cowes, Isle of Wight, was handed the building contract for the vessel, to be named HST Ella. The award-winning Chartwell Marine was founded in December 2017 with offices now in Bursledon, Southampton, and offers Marine Design and Naval Architecture services including full product design (from general arrangement and hull form through to vessel on the water), feasibility studies, 3D Modelling and Renders plus vessel build services and ship surveying. The shipyard, Diverse Marine, evolved from South Boats I.o.W in July 2018 when the new company’s Directors acquired the assets and equipment of their former employers, South Boats I.o.W., securing the employment of 20 staff on the site at Medina Yard, Cowes. The facility continues to build and maintain a multitude of craft (including windfarm vessels and lifeboats) as well as offering vessel design, refit and repair services.

Turning the spotlight onto the marine industry in the UK once again, the Chartwell 24 Crew Transfer Vessel was initially introduced to the working vessel scene in September 2018 when the design was launched commercially having been developed over a period of 10 years from data analysis and experience in offshore wind vessel design, alongside extensive dialogue and collaboration with CTV operators, wind farm owners and turbine manufacturers. This versatile craft was designed by Chartwell Marine and is available in two different variants, a 24.4m-long maximum length version and a 19.8m-long version that is compliant with legislation protecting the migration route of the protected Right Whale. The vessel design also underwent rigorous and scientific testing, which was conducted by Seaspeed Marine Consulting. The tests, including computational fluid dynamics (CFD) modelling and 1:12 scale model tank testing, helped in validating the sea-keeping performance, stability and manoeuvrability of the vessel. The first Chartwell 24 delivered was Seacat Service’s 111gt/2020-built Seacat Weatherly, followed by the 110gt/2020-built Seacat Rainbow, having been ordered in April & July 2019 respectively. In December 2019, Atlantic Wind Transfers signed a contract with Chartwell for two Chartwell 24 vessels for delivery in 2020-2022, constructed by Blount Boats, a shipyard on Rhode Island in the USA (built in the U.S to comply with the Jones Act). A further vessel was added for 2023. The first of these, the waterjet propelled Atlantic Endeavor, was delivered on 1st January 2021 with both vessels being of the specialised 19.8m model to conform with the American environmental and USCG regulations and legislation protecting the Right Whale. The vessel was put to work at the Dominion Energy Coastal Virginia Offshore Wind Farm to support two Siemens Gamesa turbines. The project is located 27-miles off Virginia Beach. Chartwell Marine then entered a partnership with BAR Technologies to develop next-generation offshore wind CTVs in May 2020, working on the development of 30m CTVs and 60m service accommodation and transfer vessels (SATVs) while also integrating BAR’s foil optimisation and stabilisation system (FOSS) into the Chartwell 24 CTV to improve its sea-keeping capability and manoeuvrability. On 1st July 2020 came a contract to design and build a new hybrid Chartwell 24 CTV for High Speed Transfers (HST). Diverse Marine in Cowes, Isle of Wight, was handed the building contract for the vessel, to be named HST Ella. The award-winning Chartwell Marine was founded in December 2017 with offices now in Bursledon, Southampton, and offers Marine Design and Naval Architecture services including full product design (from general arrangement and hull form through to vessel on the water), feasibility studies, 3D Modelling and Renders plus vessel build services and ship surveying. The shipyard, Diverse Marine, evolved from South Boats I.o.W in July 2018 when the new company’s Directors acquired the assets and equipment of their former employers, South Boats I.o.W., securing the employment of 20 staff on the site at Medina Yard, Cowes. The facility continues to build and maintain a multitude of craft (including windfarm vessels and lifeboats) as well as offering vessel design, refit and repair services.

Express Delivery

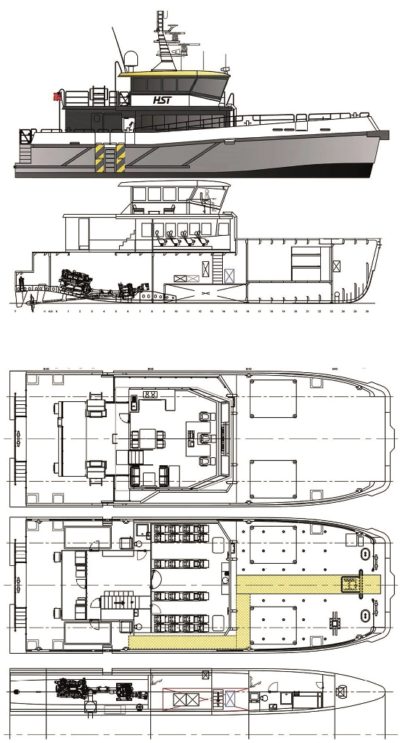

Following the order being placed for the HST Ella in July 2020, the keel was laid in August 2020 with delivery following in August 2021 to High Speed Transfers (HST). Those familiar with iconic rail travel in Great Britain will instantly associate HST with the famous Intercity 125 Highspeed Train, with these 1970s trains still gracing the tracks across the UK in the 21st century. However, in this instance, HST is the abbreviation for the Swansea-based offshore logistics company that was founded in September 2017. HST handles the crew transfer of technicians for construction and maintenance of offshore platforms, cargo transport to offshore platforms, undertakes ROV support, dive support, survey and guard vessel operations and more. The initial fleet of four vessels consisted of the 135gt/2018-built HST Hudson, 242gt/2019-built HST Harri, 135gt/2019-built HST Sofia and 132gt/2020-built HST Euan. The vessels are all from the range of Fast Crew Supplier 2710 Fast Twin Axe Crew Supply Vessels built by Damen Group. Following the order for the HST Ella, HST acquired 2 crew transfer vessels from Gardline Ltd. in October 2020, namely the HST Thomas and HST Grace (formerly the Marian Array and Gardian 14/Scoot 2). These 21m long and 12 passenger CTV were refurbished for introduction scheduled for 2021. The HST Grace operated for the short-lived Scoot Ferries November-December 2015 between Cowes and Portsmouth, with capacity for 41 passengers. HST also signed a contract with Damen Shipyards for the delivery of a Multi Cat 2309 in late 2021 and, in March 2021, a deal was sealed for two BARTech 30 CTVs from BAR Technologies, and an additional hybrid Chartwell 24, with BAR Technologies’ Foil Optimised Stability System (FOSS), from Chartwell Marine, underlining the company’s status as a pioneer in next-generation vessel design. The vessels will all be built at Diverse Marine, on the Isle of Wight. The 120gt/2021-built HST Ella was launched into the River Medina, Cowes, on 27th May and given a champagne naming ceremony the following day. Upon completion of trials, the newbuild was delivered to High Speed Transfers on 13th August before being deployed on the East Anglia 1 Windfarm, operating from Lowestoft. HST’s Hybrid Chartwell 24 is a revolutionary crew transfer vessel (CTV) that refines the formula for offshore wind support and has been described as hitting a “sweet spot” in terms of size and capability compared to other CTV designs currently operating in the offshore wind market. The HST Ella is 25.10m long overall with an 8.63m beam, a hull depth (amidships) of 3.42m, an operational draught of 1.10m and a deadweight of 26.6t. The Chartwell 24 offers a number of key technical innovations to the market including advanced engine and hull design, a large foredeck (70m2) and safety features such as step-free access, sliding handrails and unrestricted visibility from the wheelhouse. Another huge bonus was the fact that the vessel design offers high levels of operational familiarity for crews and technicians, meaning that the newbuilds have the ability to fit seamlessly into some existing fleets. The deckhouse has the capacity to accommodate a maximum of 24 personnel on Modell Bahama Diplomat Business Class Seats so technicians can travel in comfort at transit speeds whilst crew transfers can also be implemented efficiently and safely even at wave heights of 1.75m due to the vessel’s advanced hull form, high bollard push of 19.6t and a superior bow height. The accommodation also includes power points and on-board Wi-Fi. The overall cargo area on board is 90m2 with the spacious foredeck having a load capacity of 1.75t/m² and can accept two 10ft containers. The deck equipment includes a dedicated boarding gangway, deck crane and cargo tie-down points. The forward part of the wheelhouse houses a skipper seat with a full-height forward window for unrivalled visibility. Aft in the wheelhouse is an area for the standard crew of 3-4, including a sofa and coffee table area. On the main deck, aft, there is a dedicated wet room with space also available for changing and storing technician baggage. Below deck in the forward area of the hulls are 4 crew bunks plus one en-suite cabin.

The HST Ella is the first Chartwell CTV of her type to offer a hybrid propulsion system, incorporating electric motors alongside diesel engines, which allows her to deliver silent, zero-emissions operation at lower speeds, enabling compliance with port air quality requirements. The machinery spaces are located aft in the twin hulls with one Caterpillar C32 marine diesel unit in each of the two engine rooms. These 4-stroke turbocharged V12 engines have a displacement of 32,100cm3, a cylinder bore of 145mm, a piston stroke of 162mm, a compression ratio of 15.3:1 and an idle to maximum rpm range of 545-2,350. The engine management is electronic (ACERT) with mechanical failsafe. Power output is 1,417kW and each unit has a dry weight of 3.075t. The C32 engine is generally up to 2,284mm long, 1,587mm high and 1,528mm wide. As a market first for a modern CTV, besides the system being coupled with the vessel’s advanced hull form for reduced frictional resistance, the engines use Hydrotreated Vegetable Oil (HVO30) as fuel. HVO Renewable Diesel is a premium fossil free diesel product made of 100% renewable raw materials, which does not release any new carbon dioxide into the atmosphere. It is produced by hydrotreatment of vegetable oils and/or animal fats, and the result is a premium quality fuel with a chemical structure almost identical to regular diesel and can therefore fully replace fossil diesel. Pure HVO, HVO100, can be used in diesel engines without modification and is approved for all heavy vehicles of the market leading engine manufacturers such as Scania, Volvo, Mercedes, MAN among others. Fossil free diesel HVO is significantly better for the environment than fossil diesel, while keeping up with equal performance. HVO can be used immediately without modification of engines or infrastructure. In addition, HVO has better combustion, filterability and cold temperature resistance than other diesel products in the market. The HST Hybrid Chartwell 24 is propelled by a twin Servogear Ecoflow Propulsor, controllable pitch propeller (CPP) system with 1,200mm diameter propellers. These are driven by the main engines via two Servogear HD295PTIL gearboxes. Due to the hybrid capability, each of the two CPP systems can also take power from a high efficiency Danfoss Editron 200kW electric motor. The HST Ella’s electric mode can propel her at speeds of 10-15 knots compared to a top speed of 29 knots in full diesel mode. The Corvus Dolphin hybrid battery system consist of four banks of Corvus 46.4kWh batteries. The arrangement has a Brunvoll Mar-El integrator and an overall energy storage capacity of 188 kWh, with the cells being recharged during diesel propulsion mode. The operating modes are DM Mode, both main engines running and engaged – combinator curve no. 1 in the control system is selected for this mode. Maximum available power for propulsion is supplied by both engines and charging is available for the installed batteries; EL Mode: Both main engines disengaged and electric motors used for propulsion. Power source is battery only – combinator curve no. 2 in the control system is selected with this mode offering a limited running time depending on the level of battery charge, Hybrid Mode, one main engine providing power to a propeller whilst it’s electric motor runs as a generator charging the onboard batteries. The other propeller can be driven by the electric motor with power supplied from the battery banks – combinator curve no.3 in the control system is selected for the main engine driven propeller and likewise combinator curve no.4 for the electric motor driven propeller. The hybrid mode has no running time limitation and maximum power is available for propulsion from both main engines and both electric motors.

Design Advance

One innovation not selected for the HST Ella, but has been for her newbuild sister, was the aforementioned new foil optimisation and stability system (FOSS) designed by BAR Technologies. The system enhances vessel stability, improving comfort for technicians, and creating substantial operational efficiency gains without compromising service speed. The addition of the FOSS to the Chartwell 24, with its high payload and large deck space, will help dampen pitch and roll, further enhancing seakeeping capabilities and manoeuvrability. Optimising the vessel in this way also contributes to reduced fuel burn and emissions, with efficiency savings of up to 15%, representing a valid alternative to rival, or at least compliment, hybrid designs. Judging by the images released, the foil system incorporates a large foil between/beneath the hulls towards the bow with a small foil located further aft, beneath each hull. HST’s next Chartwell 24 newbuild will feature the foil technology whilst the first newbuilds to have the system fitted will be Seacat Services’ Seacat Sceptre and Seacat Sovereign.

Comments

Sorry, comments are closed for this item