The Newbuild of the Month features highlight a wide selection of vessels as they take their place in the 21st century shipping scene from Pilot Launches and Tugs to Subsea Rock Installation Vessels and mega Cruise Ships. Some often overlooked types are included and this month is no exception as another unassuming workhorse, a Pusher Tug (also known as a Push Tug), takes centre stage. With an overall length of 24.90m, a beam of 12.50m and a draught of 3.30m, the Island Raider is one of two sister ATB Tugs (Articulated Tug Barge) built for Island Tug & Barge of Burnaby, British Columbia, Canada, a subsidiary of Tidewater Canada Inc. The new series of tugs was designed by Robert Allan Ltd. of Vancouver, British Columbia, Canada. This world-renowned business was founded in 1930 when Robert Allan commenced private practice as a consulting Naval Architect after serving as Technical Manager of a local major shipyard. A 1907 graduate naval architect from the University of Glasgow, he was responsible for numerous enduring designs produced for the growing British Columbia fishing fleet and coastal ferry services, among others. Robert F. (Bob) Allan joined his father in the practice in 1945. The business grew steadily and was instrumental in the development of specialised tugs and barges for the forestry and mining industries along the B.C. coast, and for many unique shallow-draught vessels for Canada’s remote Northland. Incorporated as Robert Allan Ltd. in 1962, the company continued to expand and achieved international recognition for the high standards and performance of its many unique designs. In 1973, Robert G. (Rob) Allan joined the company, following the family tradition and succeeded his father in 1981 as President, leading the company into a new generation of computer-based design technology. The expanding firm created a wide range of distinctive designs including modern high-performance ship-assist and escort tugs, icebreakers, government service vessels, and fast craft. With significant growth since the mid 1990’s the firm has established itself as an international force in commercial working craft design.

The Owner of the ATB Tugs is Island Tug and Barge Ltd., a company that can trace its roots back to 1958 by way of cable-laying operations in B.C.’s Gulf Islands. In 1962 the assets of Coal Island Ltd. were purchased and, due to the inadequacy of existing services, a tug and barge combination was purchased in 1964. This acquisition somewhat accidentally resulted in a towboat business being established by then company Owner Peter Shields. The following year Shields Navigation Ltd. was created to take over marine operations with Coal Island Ltd. remaining as the parent company.

The company later became Shields Navigation and Standard Towing and in the period 1970s-1990s a series of barges were built, managed by third parties, to serve companies wishing to control their own transportation requirements. Shields Navigation was one such third party with ownership of the barges passing to the company in the 1990s when the priorities of Oil Companies changed.

Peter Shields therefore created a new company, International Tug and Barge (ITB), to be the primary entity for owning and managing the oil transportation fleet. ITB established contracts encompassing shipping operations from South East Alaska to Puget Sound. With a sizable commitment to the acquisition of new equipment, the stage was set for the primary role that ITB would play in the tug and barge and oil transport industry. Several mergers later saw Island Tug merge with Vancouver Tug to form what is now Seaspan International Ltd. in 1970. Sixteen years later, Peter Shields acquired a controlling interest in Seaspan and Vancouver Shipyards from Amasco in partnership with 3 other investors and, in 1993, Coal Island Ltd. purchased the name Island Tug and Barge Ltd. from Seaspan and restarted the company. The name ITB can be traced back beyond the formative years of the modern-day company to 1935 when the then Island Tug & Barge employed the tug Island Planet. By 2000 a number of separate marine companies were operating, including International Tug and Barge, Standard Towing, Seatow Marine, Island Tug and Barge and Shields Navigation. Brand recognition was becoming confusing so in the late ‘90s companies began to join together with the final merger occurring between Shields Navigation and Island Tug and Barge in 2000 leaving the single entity, Island Tug and Barge Ltd. In 2005 ITB made its first delivery to the Canadian Arctic with ATB Island Trader followed by annual voyages until 2012. A newly retrofitted and ice strengthened Cindy Mozel, together with the Island Tugger and tank barge ITB Supplier, then established a new base in Tuktoyaktuk. In the following year, ITB designed, built and delivered four new double-hulled tank barges from China to join the fleet in Tuktoyaktuk which became the first modern double hulled barges in operation on the McKenzie River. The group of companies (composed of ITB Subsea, ITB North, ITB Fuels, and Island Tug and Barge) were gathered under the umbrella of ITB Marine Group in 2013 with Tidewater Canada Inc. acquiring ITB from the Shields family in 2017, the first occasion that ownership had changed in over 50 years. Tidewater itself has a long history with the original company appearing in 1932 to form Tidewater Barge Lines. Considerable growth and diversification followed over the years with the company now being known as Tidewater Infrastructure Holdings Inc.

Pushing Ahead

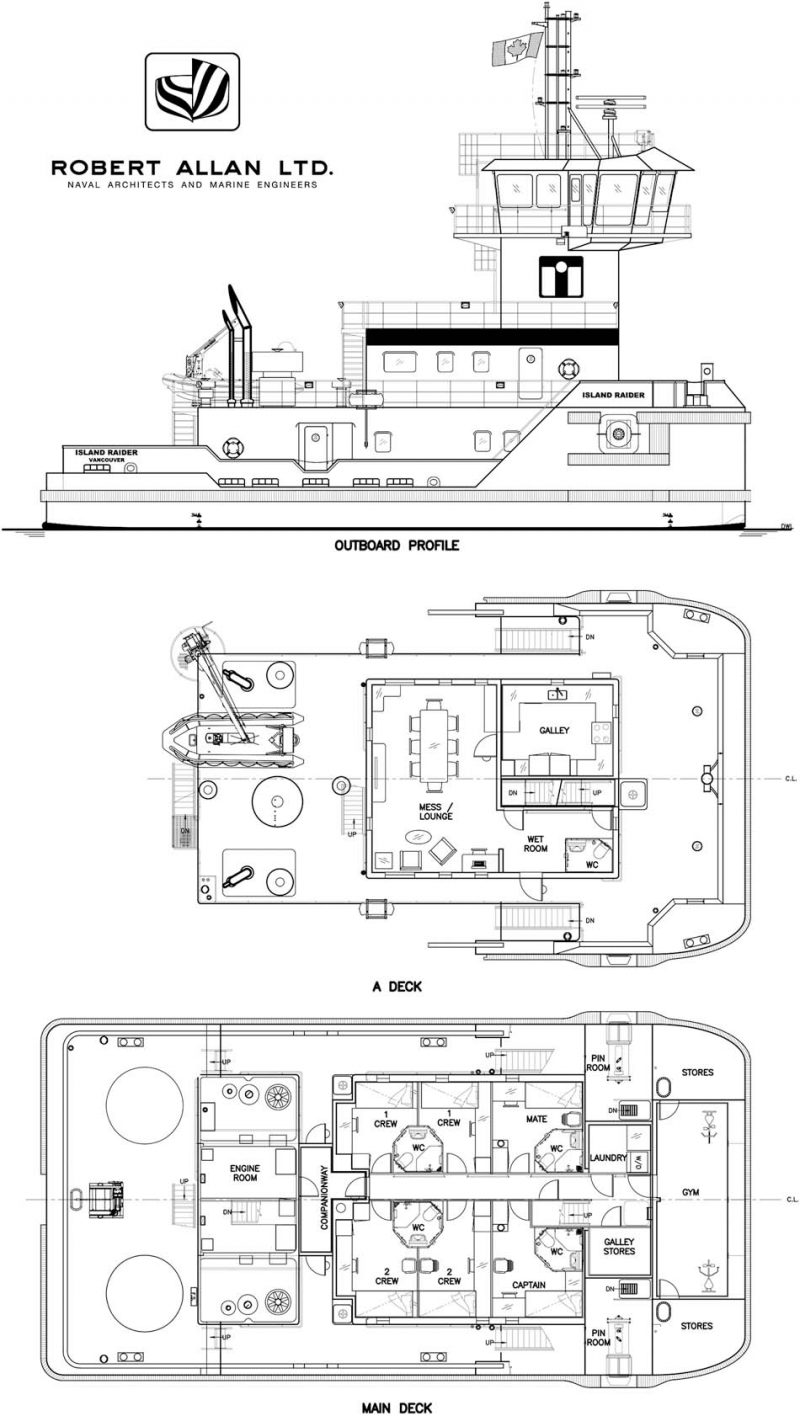

Prior to the takeover by Tidewater, ITB placed an order for two new ATB Pusher Tugs at its own Annacis Island Shipyard in Delta with construction getting underway during 2015 within a huge pair of leased warehouses on the Fraser River. The keel laying took place on 7th December 2015. These vessels would join ITB’s fleet of 8 tugs and 11 barges but as Pusher Tugs only without any provision of towing equipment. During an emergency, a towing bitt mounted on the foredeck will hold the emergency towing cable on the barges, allowing the tug to hold the barge in position. The company’s first ATB came about following the conversion of the 453gt/1966 built Island Monarch back in 2003. The aforementioned dimensions of a length of 24.90m and a 12.50m beam fall below the 25m long/500gt threshold for SOLAS regulations and the tugs are designed for ITB’s refined oil tank barge routes between Vancouver, Vancouver Island and Puget Sound, all of which are in relatively sheltered waters. The hulls of the Island Raider and sister vessel Island Regent were completed in May and then loaded onto the 100m long Dynamic Heavy Lift barge, the Dynamic Beast, which is equipped with a 900 tonne Manitowoc M-1200 Ringer crane and a 230 tonne Manitowoc 4100 crawler crane, in partnership with Mammoet. The logistical manoeuvre of relocating the vessels from the covered building areas to the quayside was quite an exercise and even involved the raising of some power lines. The duo was then shipped to Burrard Inlet, Vancouver, where both were lowered into the water for the first time on 2nd June 2018. The first vessel was then fitted with deck equipment, completed and commissioned. The articulated tug was delivered on 16th August 2018 and then christened on 28th September during an afternoon ceremony at ITB’s headquarters in Burnaby, British Columbia. After Reverend Mark Schwab from St. Stephen’s Church delivered a blessing, Beth Vandemoor, ITB’s payroll/invoice manager and long-term employee, broke a champagne bottle over the vessel’s hull while a group of ITB and Tidewater Canada Inc. employees, vendor representatives, and business partners cheered from the shore.

The design of this new generation of Pusher Tugs underwent extensive research and development with optimum hull efficiency being a primary factor in the process. The design features a broad bow that is designed to fit tightly into the barge notch for optimum water flow efficiency. Forward, a raised forecastle deck contains an Articouple FRC 35S pin system built by Japanese firm Taisei Engineering Consultants. Two hydraulically powered pins slide horizontally from the pin chambers in the bow of the tug and engage into vertical slots in the barge to create a semi-rigid connection. The self-aligning coupler system lets the tug compensate for changes in the barge’s draught during loading/ unloading by remote control from the wheelhouse. The coupling system is designed for a 3m significant wave height operating ceiling and allows for relative vertical movement/pitching but not rolling. The double hulled refined petroleum products barges that work in tandem with the tugs, the ITB Resolution and ITB Regent, both underwent modifications at Vancouver Shipyard (pin ladders and stern extensions) in readiness for the delivery of the newbuilds.

The Island Raider features a 4-deck layout and was designed with considerable emphasis on crew comfort and endurance. By incorporating Sika vibration and sound dampening floors, and Norac wall and ceiling panelling, noise levels register at less than 59 decibels in the wheelhouse during vessel operation, which is equivalent to an air conditioner. In addition, fully heated and air-conditioned accommodations can house up to eight persons in six cabins. The standard crew is four, master, mate and two deck hands. Within the steel A-Deck deckhouse can be found the engine room (aft) which is separated from the accommodation by a companionway. There are four crew cabins, 2 singles on the port side and two twins (bunk beds) on the starboard side with shared facilities. Forward of these areas are the Captain and Mate en-suite cabins. Ahead of the sleeping area is the raised forecastle that contains the two hydraulic pin rooms, stores, laundry, workshop, galley stores and the gym in the bow. Above on the aluminium B-Deck can be found a spacious mess room, stainless-steel finished galley and a wet room. From B-Deck, stairs lead up to a smaller cabin area for the HVAC and wheelhouse electronics. Above on A-Deck is a large wheelhouse, 12 metres above the water providing the helmsman with a 12.3m clear line of sight. The wheelhouse also boasts a full walk around outer deck and 360 degree visibility via full-height windows for optimal situational awareness. The navigation equipment is supplied by JRC Alphatron, including radar, electronic chart display, weather station, bridge navigation watch alarm system, magnetic compass and automatic identification system. Deck equipment consists of a Burrard Iron Works E3W aft-mounted anchor winch, a Palfinger Ned-Deck SOLAS davit with Polaris self-righting rescue boat and Schuyler Companies laminated fendering around the hull.

Working Partnership

The Island Raider is powered by a pair of V-12, IMO Tier II-certified Cummins KTA38M engines that each produce 634kW (850bhp) at 1,800 rpm. The 38 litre KTA38M engines are 2,152mm long overall, 1,462mm wide, 2,083mm high and 4218kg in weight. The bore stroke is 159mm and the bore diameter is also 159mm. Centa hollow carbon fibre floating shafts connect the engines to two Rolls-Royce Z-drives via integral slipping clutches. These are US105 FP azimuthing thrusters with a Kaplan style four-bladed and 1,600mm diameter in-nozzle propeller. The engines and their systems are entirely independent, allowing propulsion if one sustains a catastrophic failure. There are considerable benefits in manoeuvrability from the use of Z-drives as these units can rotate 360 degrees. Fuel savings of 25% are achieved using this set-up and the Island Raider can turn 360 degrees in her own length in 20 seconds. A fully laden tug/barge combination can perform a crash stop in just over one length (102.86 metres) of the ensemble. Additionally, the ATB pushing arrangement brings with it substantially higher efficiency over conventional towing. As an example, one of ITB’s existing tugs, the Island Scout, tows barges at about 5.8 knots loaded and about 7 knots empty. With identical twin KTA38 main engines, the 162gt/2006 built Island Raider can achieve 8 knots loaded and 10 knots empty at the same rpm with the same capacity barges. The engine room is also equipped with two John Deere 4045 AFM85 generators, producing 99 kW of electrical power each. The machinery space fire extinguishing system is of the Kidde FM200 type.

Upon delivery, the Island Raider was partnered with the 77,96m long, 20.15m beam, 3.95m maximum draught and 2,414gt tank barge ITB Resolution. This Oil Tank Barge was built in 2007, has 12 cargo tanks and a 95% capacity of 4,200m3. Four Goulds Centrifugal pumps with a capacity of 350m3 per hour are installed for loading/unloading. The combined length of tug and barge is 102.86m and the barge is fitted with 500hp Schottel omnidirectional pump jets at the bow. These thrusters are commonly used on inland waterway barges in Europe and draw water through a flat grid on the barge’s bottom. The water is then driven out through thruster ports that give the barge 360-degree propulsion control. This, together with the tugs’ Z-drives, allow the ATB unit to effectively walk sideways parallel to her moorings. The remote-controlled thruster can propel the tug and barge unit at 5 knots. When transitting narrow sections of the route, such as the Narrows in Vancouver Harbour, the thruster is placed on standby mode for immediate response. Unlike conventional bow thrusters, these Schottel units are still effective while the ATB is underway. Sister vessel Island Regent is due for delivery in February 2019.

Special thanks must go to Ernst Schneider of Robert Allan Ltd and Carolyn Matt of ITB Marine Group for all the invaluable help with information, images and diagrams.

TECHNICAL SPECIFICATIONS

| Designer | Robert Allan Ltd |

| Builder | Island Tug & Barge Ltd |

| Location | Annacis Island Shipyard, Derwent Way, Delta |

| Hull No. | 1 |

| IMO | 9802360 |

| Keel Laid | 7th December 2015 |

| Launched | 2nd June 2018 |

| Delivered | 16th August 2018 |

| Christened | 28th September 2018 |

| Service Debut | 4th November 2018 |

| Flag | Canada |

| Port of Registry | Vancouver |

| Ship Manager | Island Tug & Barge Ltd., Unit 310, 10991, Shellbridge Way, Richmond BC V6X 3C6 |

| Ship Owner | Island Tug & Barge Ltd., Unit 310, 10991, Shellbridge Way, Richmond BC V6X 3C6 |

| Operating area | West Canada |

| Employment | ATB pushing petroleum products barge |

| Type | Sea-going ATB |

| Class | Lloyd’s Register |

| Classification | LR 100 A1 Tug, MCH, IWS, UM |

| Gross Tonnage | 384 |

| Deadweight | 90 |

| Length Overall | 24.90m |

| Length b.p. | 23.90m |

| Moulded Beam | 12.50m |

| Draught (Design) | 3.30m |

| Lightship Displacement | 259.39t |

| Lightship Draft | 2.77m |

| Fully Loaded Displacement | 347.58t |

| Fully Loaded Draught | 3.57m |

| Hull Depth (minimum) | 3.65m |

| Bridge Clearance | 21.00m |

| Line of Sight Height | 12.30m |

| ATB light-ship speed | 10 knots |

| ATB full-load speed | 8 knots |

| Crew | 8 (Generally 4) |

| Crew Cabins | 6 |

| Crew Beds | 8 |

| Machinery | 2x Cummins KTA38M |

| Power Output | 634 kW each (850 BHP) @ 1800 rpm |

| Propulsion | 2x Rolls Royce US 105 P9 12FP Z-drives with 1.6 m propellers & integral slipping clutches. |

| Auxiliary Engines | 2x John Deere 4045 AFM85 with Stamford Generator UCM274E1, 99 kW |

| Bollard Pull (Ahead) | 21t/1,700bhp |

| Wheelhouse electronics | JRC Alphatron |

| Communications | Cobham Satcom |

| ATB coupler | Articouple FRC 35S pin |

| Tank Capacities at 98% | |

| Fuel oil | 99.8 m³ |

| Potable Water | 14.4 m³ |

Comments

Sorry, comments are closed for this item