Estonian ferry operator Tallink has blossomed considerably over the past 16 years since the construction of the 40,803gt/2002 built cruise ferry Romantika. Since then a further seven conventional ships have been built for Tallink namely the Baltic Queen, Baltic Princess, Galaxy, Victoria I, Star, Superstar and, in 2017, the Megastar. The company has also acquired the operations and ships of Silja Line, the 35,154gt/1989 built Isabelle (formerly Viking Line’s Isabella) and has chartered out Superfast VII/VIII to Stena Line (Cairnryan- Belfast) plus the Superfast IX, which currently operates as the Atlantic Vision for Canada’s Marine Atlantic. Tallink’s history can be traced back to 1965 when the Soviet Union-based Estonian Shipping Company (ESCO) commenced a service between Helsinki and Tallinn with the Vanemuine. Regular year-round services began in 1968 with the Tallinn, which served on the route until she was replaced by the new Georg Ots in 1980. In May 1989 ESCO formed a new subsidiary, Laevandusühisettevõte Tallink, together with Finnish company Palkkiyhtymä Oy. Tallink became a fully Estonian-owned company in 1993 when Palkkiyhtymä sold its shares. In 1994 Tallink attempted a Helsinki-Tallinn-Travemünde service. In September 1994 the Helsinki-Tallinn operation adopted the Tallink name and the route’s second large ferry arrived in 1997 in the form of the 25,772gt/1982 built Normandy (ex-Stena Normandy) prior to her moving on to Irish Ferries. The first sizeable ship was the Meloodia and the Normandy was replaced by the Fantaasia in 1998. In July 1998 Tallink purchased the freighter Kapella to open a service between Paldiski and Kapellskär, Tallink’s first route to Sweden. The Tallinn-Stockholm link came under Tallink’s wing in 2000 from Est Line and in 2002 AS Hansatee changed its name to AS Tallink Grupp. This was the catalyst for growth as in May 2002 the Romantika was delivered to the Helsinki-Tallinn service. In 2004 three new ships joined Tallink’s fleet, HSC Tallink AutoExpress 3 and HSC Tallink AutoExpress 4 plus the Romantika’s sister ship Victoria I for the Tallinn-Stockholm route. The latter replaced the Fantaasia which in turn opened a new route from Helsinki to St. Petersburg via Tallinn, which ceased in January 2005. In 2006 Tallink also purchased the Baltic Sea operations of Superfast Ferries from the Attica Group and opened a route between Riga and Stockholm using the Fantaasia (replaced by the Regina Baltica). The 48,915gt Galaxy replaced the Romantika on the Tallinn-Helsinki route, the latter transferring to Tallinn-Stockholm. The highspeed service also ceased this year and Silja Line was purchased from Sea Containers Ltd. From 2007 the former Superfast ships were repositioned under the Tallink brand and their route changed to Tallinn-Helsinki-Rostock. The 36,249gt Star was also delivered for Tallinn-Helsinki. Two new ships followed in 2008 in the form of the 36,277gt Superstar (for Tallinn-Helsinki) and the 48,915gt Baltic Princess. The latter replaced the Galaxy, which was transferred to Silja Line in place of the Silja Festival. The “odd one out” in the newbuild cavalcade was the Italian built 36,277gt Superstar as her design was based on Moby Lines’ Moby Wonder. The original order included an option for a second ship of the same type, which Tallink decided not to exercise. In November 2008 the Superfast IX went to Marine Atlantic and in April 2009 the 48,915gt Baltic Queen was delivered to the Tallinn- Mariehamn-Stockholm service alongside the Victoria I. The Romantika then switched to the Riga-Stockholm route. Financial issues subsequently affected the company in the wake of the massive investment made since 2002 but this stormy patch was ridden out. Debts incurred included €470m for purchasing Silja Line and €310m for Superfast Ferries. The Superfast duo were withdrawn in winter 2009-2010 and then reinstated to the Helsinki-Rostock link in April 2010 before withdrawal and charter to Stena Line after the 2011 season. Other tonnage not named here passed through the fleet as Tallink evolved and expanded including the much loved 10,002gt/1974 built Vana Tallinn and the unique 13,875gt/1980 built Regina Baltica. AS Tallink Grupp is now the leading passenger and cargo transportation service provider in the Northern region of the Baltic Sea, recording record carryings and substantial profits. The company owns 17 vessels and operates under the brands of Tallink and Silja Line on 6 different routes. The Group employs 7,000 people and annually conveys up to 9 million passengers.

The pinnacle of the Tallink fleet thus far, and indeed a new icon of the ferry scene, was arrived at on 11th December 2014 when the company announced that it had ordered a new environmentally friendly and 27 knot Ro-Pax ferry from Meyer Turku for the Tallinn-Helsinki route shuttle operations. The newbuilding, to be built in Turku, was due for delivery in early 2017. The 212m long and 2,800 passenger capacity ship would cost around €230m, provide approximately 2,000 man-years employment for the shipyard and be LNG powered. This new prototype of ferry provided an excellent opportunity to apply improved design & building methods to a blank canvas. The LNG specification follows Viking Line’s lead with the 57,565gt/2013 built Viking Grace and ensures that the ship complies with the new emission regulations for the ECA areas, which include the Baltic Sea. The Tallink Group was by this time in fine fettle once again having generated a €27.3m profit in 2014 and the newbuild contract was formally signed on 27th February 2015. According to the contract, 20% of the total cost was to be paid during the construction period and the rest upon delivery of the vessel. Tallink financed the project with a €184m long term loan from Nordea Bank guaranteed by Finnish Export Credit Agency Finnvera. The Megastar is also co-financed by the European Union’s Connecting Europe “Motorways of the Sea” programme. The total expenditure for the Twin-Port 2 project (including double deck linkspan construction at both ports and a new terminal at Helsinki) was €97.6 million plus €29.3 million of aid. The new facility in Helsinki was due to be ready for use by late February so the existing berth was used initially. The total amount of the project for the Tallink Grupp was €16 million plus €4.8m of aid. The 36,249gt/2007 built Shuttle ferry Star was also converted to double deck loading in January 2017 so that she could fully use the new berth facilities. With regard to the supply of LNG for the Megastar, Tallink signed supply contracts with partners both in Finland (Skangas) and Estonia (AS Eesti Gaas). The new Helsinki West Harbour berth also has an automated vacuum pad mooring system for the Star and Megastar. These pads can hold a ship at a windspeed of up to 17m/s with additional fastenings available if conditions exceed this threshold.

A Star is Born

On 4th August 2015 construction commenced at Turku with the steel cutting ceremony for what was known as NB 1391 (the yard number). The design phase for the vessel lasted 6 months and, once the 3D digital models for the ship were ready, the first steel was cut for building the blocks for the vessel`s hull. A total of 39 block sections (maximum weight 600t) formed the ship, joined by 500km of weld seams. When completed, the ship consisted of around 108,000 individual parts and included 7,000sqm of carpets, 600km of cabling and 11,500 lighting fixtures. A naming contest was opened for the ship on 7th August and on 22nd January 2016 the name was revealed as Megastar, a natural successor to Shuttle ferries Star and Superstar. Tallink said that the name expressed perfectly the characteristics of the ship and it is easy to pronounce in Estonian, Finnish and other languages. The first person to enter the name Megastar into the competition was Janar from Estonia, who received two tickets for the ship’s maiden voyage. Altogether, over 300 entries with the name Megastar were registered in the contest, making it one of the most popular names suggested. Altogether there were 14,200 entries from Finland, 5,300 entries from Estonia and 2,050 entries through the international website. The keel-laying ceremony followed on 9th February 2016 and was witnessed by over 100 guests from Meyer Turku, Tallink and classification society Bureau Veritas. Lucky coins were placed beneath the keel of the ship, to be retrieved upon completion and kept on board for good luck. The latter involves the mast stepping ceremony, which was held on 29th September. The coins from the keel were repositioned into the ferry’s mast step for luck. On 1st July 2016 the Megastar was christened at the Meyer Turku shipyard by former president of Finland Tarja Halonen. The formality included the traditional blessing speech by the Godmother, breaking a Champagne bottle on the hull and opening the dry-dock valves for the float-out of the vessel. Tarja Halonen is a Finnish politician who was the 11th President of Finland, serving from 2000-2012, and was the first female head of state in Finland.

The 49,134gt Megastar was delivered by Meyer Turku Oy on 24th January 2017. The yard is one of the leading European shipbuilding companies and was revived via a joint venture between the Meyer family (owners of Meyer Werft) (70%) and the Finnish State via Teollisuussijoitus (30%). The 144 hectare Perno yard in Turku employs 1,350 people and specialises in building cruise ships, ferries and special project vessels. The subsidiaries of Meyer Turku are Piikkio Works Oy, which is a Cabin Factory in Piikkiö, Shipbuilding Completion Oy, which provides turnkey solutions to public spaces in ships, and ENG´nD Oy, which is an engineering company offering services for shipbuilding and offshore. The history of shipbuilding at Turku dates back to 1737. Construction of the Perno yard began in 1975 by Wärtsilä Marine, which filed for bankruptcy in October 1989. The site became Masa-Yards Turku New Shipyard in November 1989 and was taken over by Kværner in 1990. By 2002 Aker took over Kværner and already owned a shipyard in Rauma. Two years later the two facilities became known as Aker Yards and in 2008 the STX Corporation of South Korea took over Aker Yards, renaming the company as STX Europe. A financial crisis beset STX in 2012 and the Rauma shipyard was closed in 2013. The Turku Yard was awakened again by the Meyer family in 2014 under the title Meyer Turku with the German shipyard owner having since purchased the remaining shares to own the yard outright.

Presented to the World

Following her delivery on 24th January the 49,134gt Megastar was unveiled to the media on 27th January. The official maiden voyage followed at 13.30 from Tallinn on 29th January. The Superstar had made her final arrival at Tallinn just after midnight that same day and a few days later departed bound for La Spezia and her new life as Corsica Ferries’ Pascal Lota. The promotional strap line for the state-of-the-art newbuild is “Megastar -shaped to be perfect” and never a truer word was spoken. The ship’s hull is designed by Meyer Turku and features new concepts to reduce water resistance and to improve operation in icy conditions. The structure is more rigid so as to decrease overload and vibration. A total of 35 models were created to decide the best hydro-dynamic shape for the new ship. Naturally her sleek, modern lines have been designed for optimum performance, efficiency and seakeeping. The ship is propelled via five Wärtsilä marine dual fuel engines of the 50DF type, three 12 cylinder units and two 6 cylinder units. These power two Wärtsilä fixed pitch propellers via a diesel electric system. Wärtsilä’s other input to the ship includes the latest version of the Nacos Platinum integrated navigation system and external communication facilities plus the Wärtsilä Genius services portfolio to optimise operational efficiency. Wärtsilä also signed a five year maintenance agreement, which includes the Condition Based Maintenance (CBM) facility. The Wärtsilä engines power five ABB generators which then provide the electricity to drive the propellers and all of the ship’s systems. The ABB propulsion arrangement is superior to conventional mechanical systems that are optimised for a single speed. Electric propulsion, which provides a quieter, smoother environment onboard ship, is based on variable speed control permitting the engines to operate efficiently at all speed profiles, an ideal factor for a short sea crossing such as the two hour Tallinn-Helsinki voyage. Port arrivals can, if conditions permit, be handled by the smaller engines thus providing further savings. Four ABB transverse tunnel thrusters are installed for manoeuvring in port, two at the bow (2,200kW each) and two at the stern (1,200kW each). Heat generated by operational engines whilst in port is harnessed to warm the ship. Two 600m3 LNG tanks are located within Decks 1 & 2, slightly forward of mid-ships, to provide the fuel for the engines. Low sulphur diesel bunkers are also carried as per the dual fuel capability to guard against LNG system or bunkering issues. The colourless and odourless LNG requires a full safety system with plentiful sensors to detect any leak. All electrical equipment in the vicinity of the LNG system is certified as explosion-proof. The LNG is stored at -160 degrees centigrade and pressurised to 4-6 bars. The LNG handling system, which heats the LNG to return it to a gas, is provided by Linde Group Cryoplant of Sweden. The vent mast for the LNG system can be seen forward of the ship’s stylish funnel. For the time being, LNG bunkering will take place overnight in Tallinn via road tankers.

ABB has also installed the Octopus smart energy monitoring system on the ship which monitors energy use, especially fuel consumption, in real time. This technology is expected to be installed on Tallink’s other ships. In total there are over 10,000 sensors around the ship monitoring conditions. The Megastar’s “green” credentials are further enhanced by the Evac Complete Cleantech Solution that includes vacuum collection, waste water treatment, dry and wet waste treatment, fresh water generation and automation systems. The mandatory Safe Return to Port requirement forms the basis of the Megastar’s onboard safety. The ship is divided into four vertical fire safety zones. If fire or water ingress affects one zone then passengers and crew can be moved to the other areas. The bridge and other systems are duplicated to maintain safe navigation in the event of an emergency onboard.

Ferry Idol

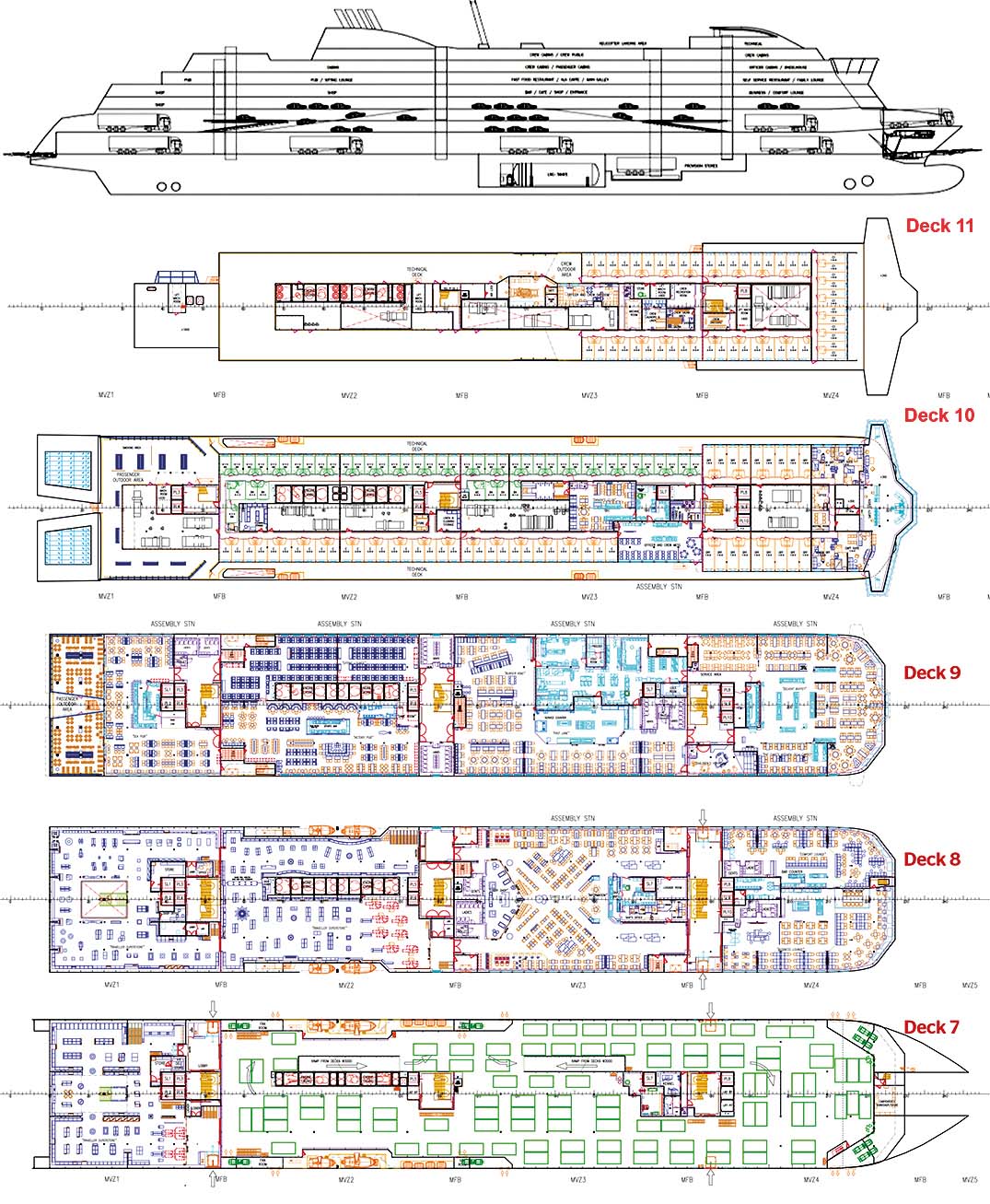

The Megastar offers 3,653 lanemetres of vehicle space, equivalent to 800 cars or the optimum load combination of 320 cars and 110 cargo units. Deck 3 is the main vehicle garage with a maximum clear height of 4.90m and 3.10m wide lanes. The deck load here is 1.5 t/m2. Looking from the stern the vehicle lanes are configured as lanes 1/2/3/4/5 leading from the starboard side, then a ‘centre casing’ followed by lanes 6/7/8 on the port side. Above on Deck 5 is a mixed vehicle garage capable of handling HGVs and cars simultaneously. The outer four lanes (1/2 & 7/8) have a 4.90m clear height and a width of 3.1m for trucks/coaches. Lanes 3/4/5 and 6 also feature hoistable mezzanine decks for cars. The car lanes are 2.4m wide and, when in use, the mezzanine decks have a clear height above of 2.10m and 2.40m below. The deck loads on Deck 5 are 0.3t/m2 for the car lanes/mezzanine decks and 2t/m2 for the HGV lanes. Internal ramps link the decks but the ship can load/unload over decks 3 & 5 concurrently. The clam shell bow doors on Deck 3 open to reveal a folding hydraulic ramp and a 6m wide and 4.9m high vehicle access. A hydraulic weather door at the bow of Deck 5 reveals a 9.0m wide and 4.9m high garage access. At the stern, Deck 3 is accessed via hydraulic ramps and two 7.0m wide and 4.9m high doors. The aft of the Deck 5 garage is open to the stern. A first for a Baltic ferry can be found on 75% of Deck 7. The equivalent of a shopping centre car park is provided for 100 cars, accessed via ramps from Deck 5. The car park remains open to passengers throughout the voyage so that shopping can be taken to vehicles. The clear height here is 2.40m with a 0.3t/m2 deck load. During peak time sailings a maximum of 150 cars can be stowed in this garage but the area is closed whilst at sea due to limited space. Aft of this area and above it on Deck 8 aft is the 2,500m2 tax free Traveller Superstore, the largest of any Baltic ferry. The store has 5 entrances, 14 check-outs, pre-order and bulk buy counters plus self-service ‘Q-shopping’ scan and shop equipment. The store has no warehouse on board with the inventory monitored by a central warehouse ashore. A further 385m2 of shopping is on offer at the Lobby Store on deck 8. Deck 7 also offers a kennel facility.

The Megastar combines a comfortable fast ferry service, social eating experience of open-layout dining areas, versatile choice of lounges and well-designed shopping solutions. Passenger areas have easy and wide access points plus a number of smart services. The ship offers seven different restaurants/ cafés and 3 travel classes, namely the standard or Star Class, Comfort Class and Business Class. For the first time, there are 2 separate lounges for Standard Class including a Driver’s Lounge. The décor on board is stylish, akin to a modern luxury hotel and designed by Finnish studio dSign Vertti Kivi & Co. The ship offers 3.1m2 of space per passenger and the public areas total 8,600sqm, spread over 4 of the 12 decks. Level 8 features the 170-seat Business Lounge forward, accessible via a €65 supplement, and this includes a restaurant, bar, meeting room and food stations. Aft of here is the Comfort Lounge where a €20 supplement applies and includes beverages and snacks. The Star Class lounge is also on this level along with the abundantly furnished 444-seat Coffee & Co. bar/lounge and passenger services desk. Above on Deck 9 is the Delight Buffet with large forward facing windows, the 60-seat Chef’s Kitchen A La Carte restaurant, a 100m2 children’s area, Fast Lane Cafeteria, the classic Sea Pub and an attractive 300-seat Winter Garden conservatory style area overlooking the stern plus the Sitting Lounge. The Victory Pub sports bar is also on Deck 9 and features an attractive horse sculpture with a lampshade on his head. This level also boasts the second Burger King restaurant at sea, the first being installed on board the Star. The Driver’s Lounge is located on Deck 10 along with the passenger cabins (port side), an outside deck aft and crew/officer cabins and facilities. Deck 11 features crew cabins, facilities, the bridge and a crew open deck. The Megastar is a shining example of a 21st century cruiseferry and has set the standards for others to follow, or strive to better.

With special thanks to Luulea Lääne, Communication Director, AS Tallink Grupp, and Tapani Mylly Communication Manager, Meyer Turku, for the information, diagrams and images

Technical Specifications

| Steel Cutting | 4th August 2015 |

| Keel Laid | 9th February 2016 |

| Launched | 1st July 2016 |

| Delivered | 24th January 2017 |

| Shipyard | Meyer Turku |

| Place of build | Turku, Finland |

| Yard No | NB 1391 |

| Owner | AS Tallink Grupp, Sadama tn 5/7, 10111 Tallinn, Estonia |

| Operator | AS Tallink Grupp, Sadama tn 5/7, 10111 Tallinn, Estonia |

| Service | Tallinn (Estonia)-Helsinki (Finland) |

| IMO | 9773064 |

| Flag | Estonia |

| Port of Registry | Tallinn |

| Classification | Bureau Veritas SYS-IBS-1, AUT-UMS (SS), SYS-NEQ-1 (SS), MON-SHAFT, GREEN PASSPORT, CLEANSHIP, INWATERSURVEY |

| Ship Type | Ro-Ro Passenger/Vehicle Ferry |

| Ice Class | 1A |

| Length Overall | 212.00 metres |

| Length (BP) | 192.60 metres |

| Beam | 30.60 metres |

| Draught | 7.10 metres |

| Hull Depth | 9.90 metres |

| Gross Tonnage | 49,134 |

| Net Tonnage | 15,621 |

| Deadweight | 6,080 |

| Freeboard | 1,312mm |

| Main Engine | 3x Wärtsilä 50DF 12 cylinder & 2x Wärtsilä 50DF 6 cylinder units |

| Dual Fuel | LNG/Marine Diesel Oil |

| LNG Capacity | 1189.3 m³ |

| Propulsion Motors | 2x ABB 20,300kW @ 138rpm |

| Propellers | 2x 5400mm diameter Solid 10.00 LB Propeller |

| Generators | 3x ABB 14250 kVA – 11400 kW – 15489 HP, 2x ABB 7125 kVA – 5700 kW – 7745 HP |

| Emergency Generator | 1x 846 kVA – 677 kW – 963 HP |

| Thrusters | 2x 2,200kW bow thrusters + 2x 1,200kW stern thrusters |

| Total Power | 40,600kW/55,164HP |

| Installed Power | 45.6MW |

| Service Speed | 27 knots |

| Boiler | 2x CHF ALFA LAVAL 9.00 bar & 2x CHR ALFA LAVAL 12.00 bar |

| Passenger Capacity | 2,824 |

| Cabins | 47 for passengers + 1x medical cabin facility |

| Crew | 176 |

| Crew Cabins | 105 |

| Passenger Capacity | 2,850 passengers |

| Vehicle Capacities | 3,653 lanemetres (800 cars or 320 cars & 110 cargo units optimum load) Deck 3: 1,200lm for freight; Deck 5: 800lm for freight + 100 cars; Deck 6: (mezzanine decks) 80 cars; Deck 7: car park 100 cars (150 maximum) |

| Vehicle Ramps | |

| Bow | 19.8m long + flaps/6m wide driving area -90t maximum load. Maximum operation inclination is +3/-7 degrees up/down |

| Stern | 2x 11.75m long ramps + 2m flaps. 7m driving width each |

| Max Clear Height | 4.60m |

Comments

Sorry, comments are closed for this item